Performthegearpumpowtestifyouidentifyasteeringorcuttingdeckraise

andlowerproblem.Thistestdeterminesifthehydraulicowfromthegear

pumpiscorrect.

TestProcedure

Note:Overaperiodoftime,thegearsandwearplatesinthegearpumpcan

wear.Awornpumpmaybypassthehydraulicuidandmakethepumpless

efcient.Aftersometime,sufcientuidlosswilloccurandcausethecuttingunit

motorstostallunderheavycuttingconditions.Continuedoperationwithaworn,

inefcientpumpcangenerateexcessiveheat,causedamagetothesealsand

othercomponentsinthehydraulicsystem.

1.Ensurethatthehydraulicuidisatnormaloperatingtemperature.

2.EnsurethatthetractiondriveiscorrectlyadjustedfortheNEUTRALposition.

CAUTION

Beforeopeningthehydraulicsystem,operateallthehydraulic

controlstoreleasesystempressureandavoidinjuryfromthe

pressurizedhydraulicuid;refertoReleasingPressurefromthe

HydraulicSystem(page4–5).

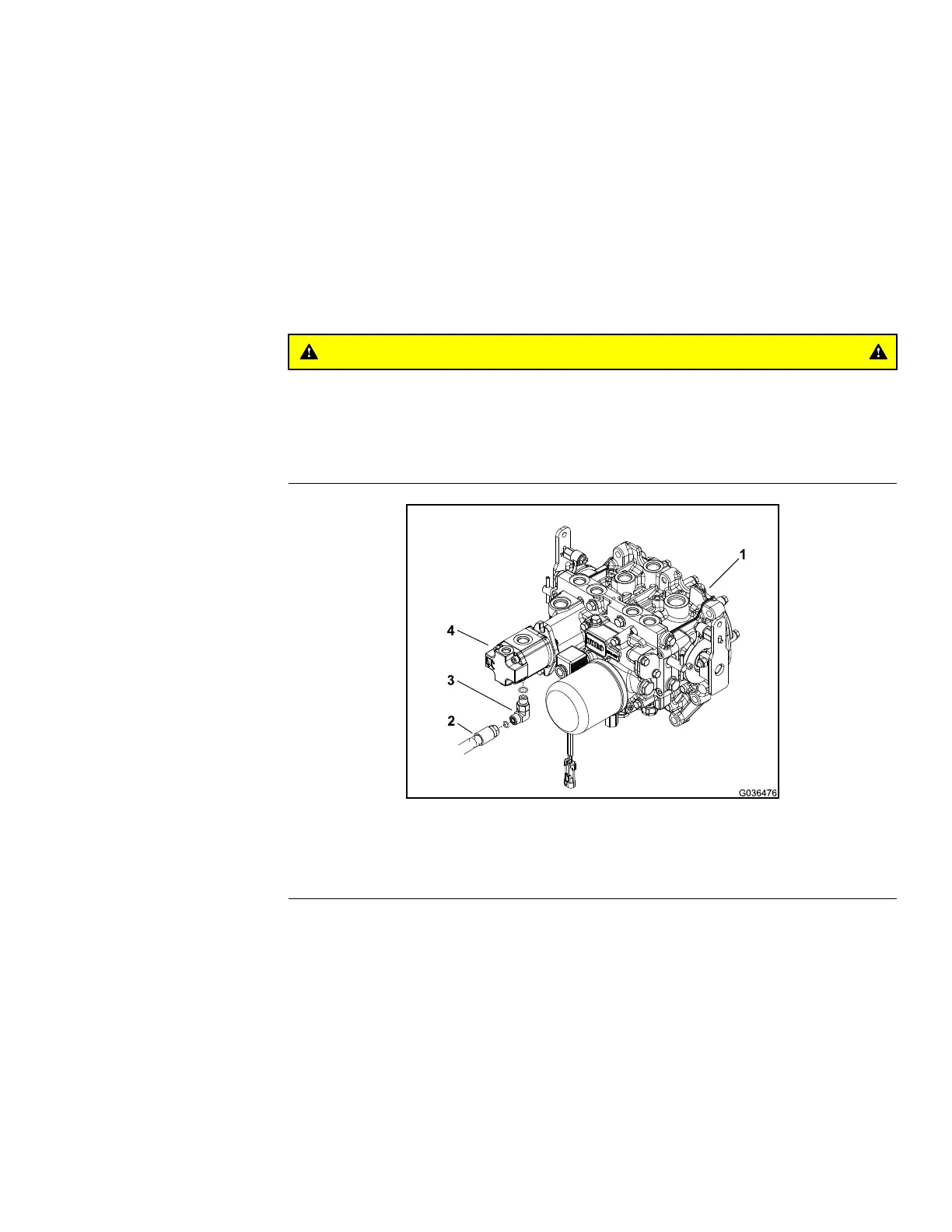

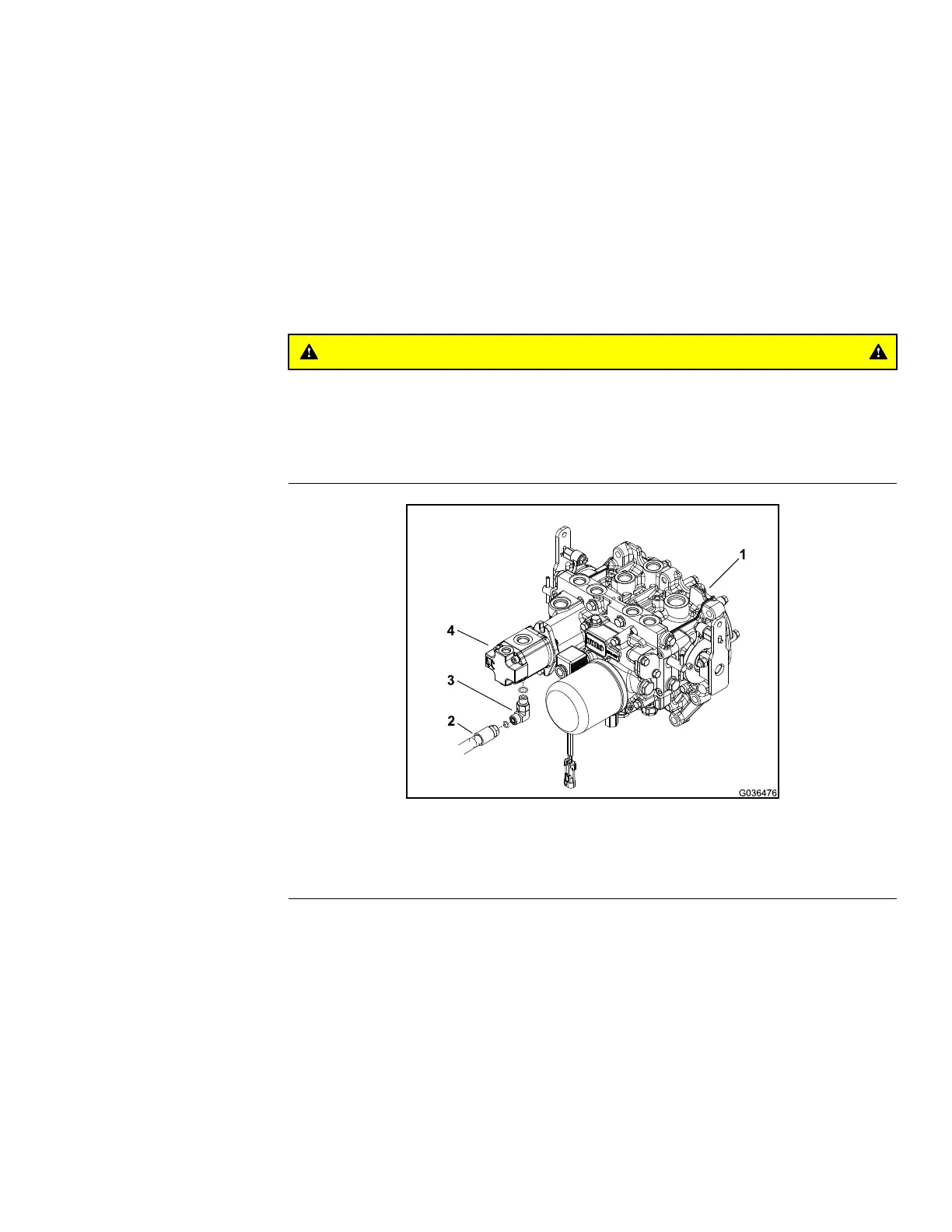

g036476

Figure57

1.Transmission

3.Lowertting

2.Hydraulichose

4.Gearpump

3.Parkthemachineonalevelsurface,lowerthecuttingdeck,shutoffthe

engine,andsettheparkingbrake.

4.ReadallWarning,Cautions,andprecautionslistedatthebeginningofthis

section.

5.Cleanthejunctionofthehydraulichoseandlowerttingonthegearpump.

6.Disconnectthehydraulichosefromthelowerttingonthegearpump(Figure

57).

7.Installahydraulictester(pressureandow)inserieswiththegearpump

ttinganddisconnectedhose.Ensurethatthetesterowarrowpointsfrom

thepumpoutletportandtowardthedisconnectedhose.Ensurethatthe

ow-controlvalveonthetesterisfullyopen.

Groundsmaster360

Page4–63

HydraulicSystem:TestingtheHydraulicSystem

16225SLRevC

Loading...

Loading...