FilteringtheClosed-LoopTractionCircuit

g036058

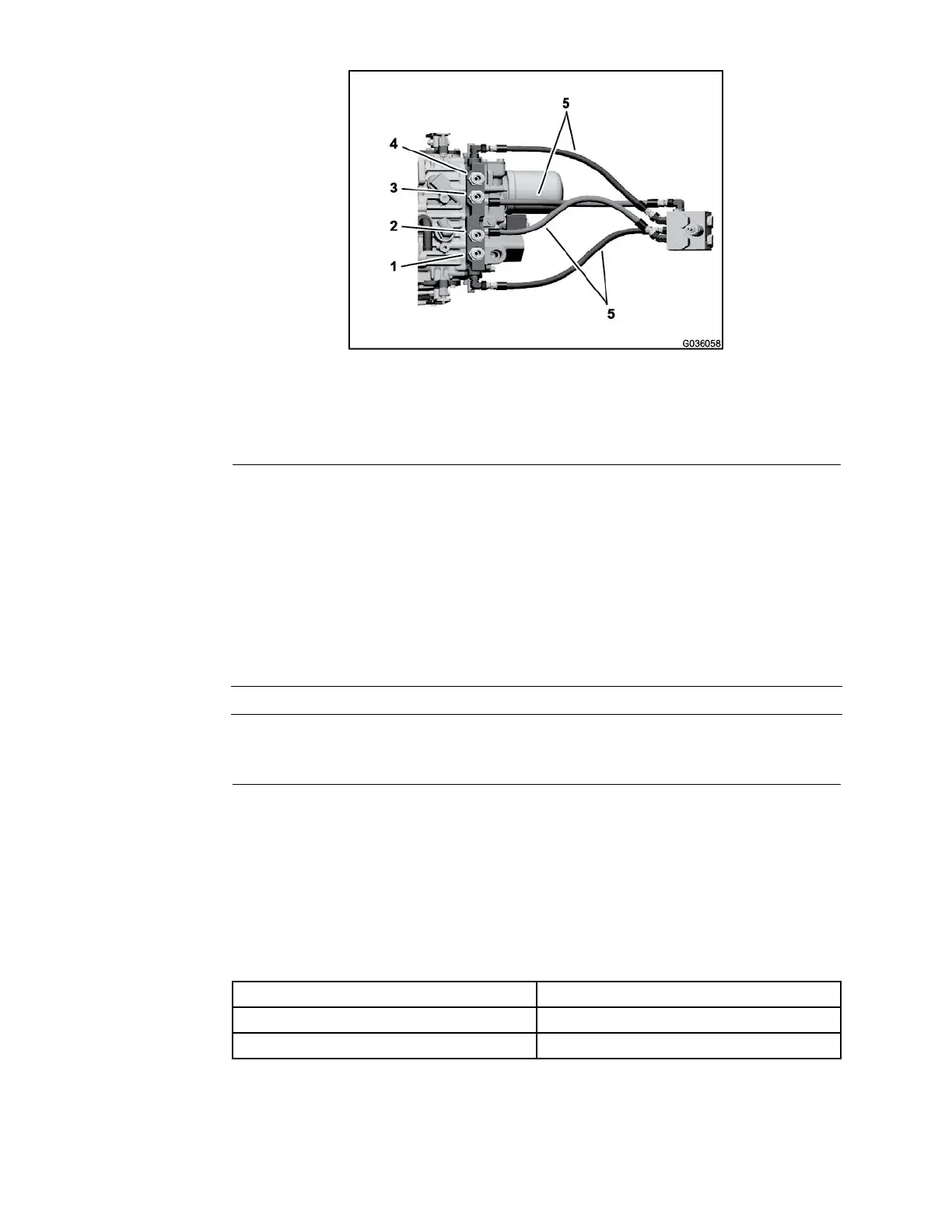

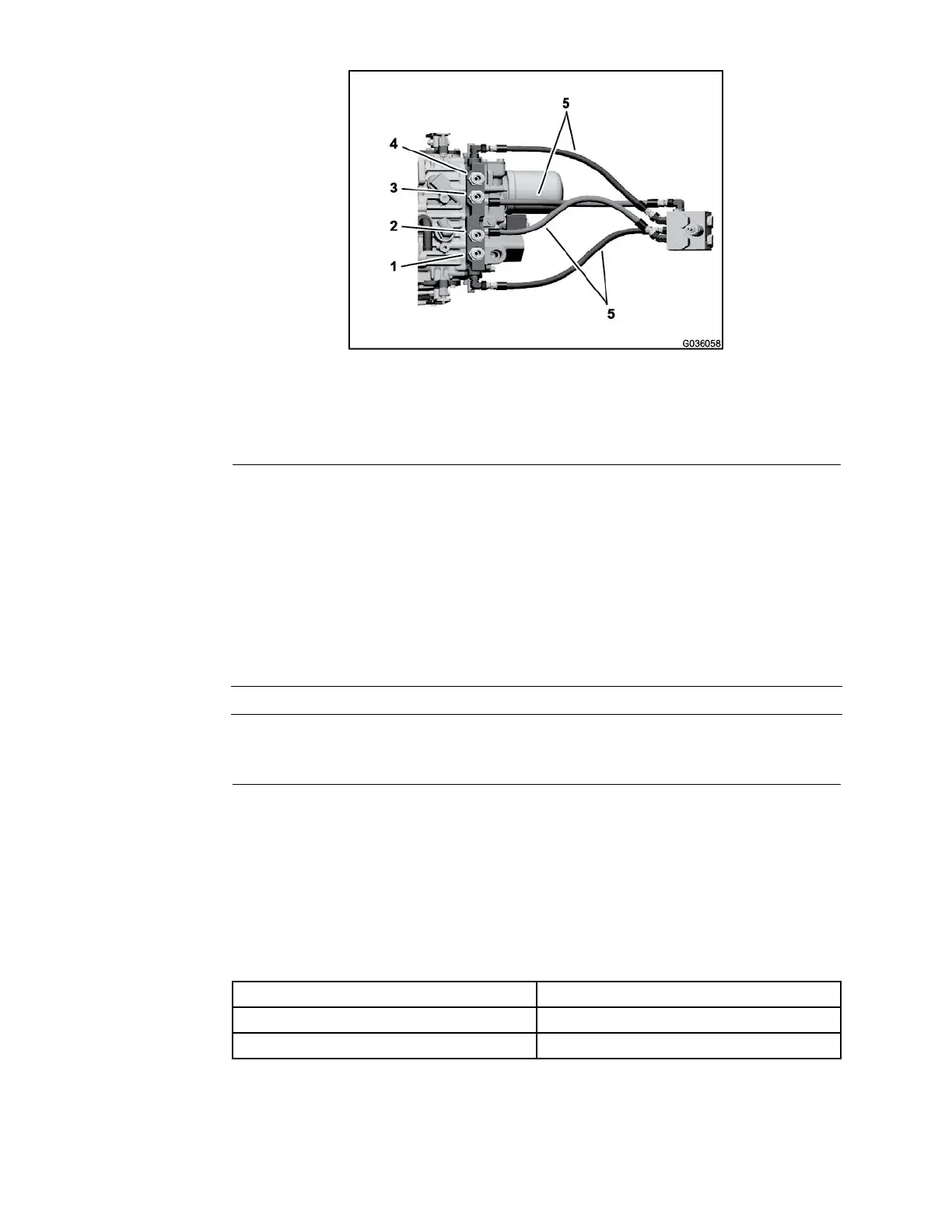

Figure61

1.PortA4.PortD

2.PortB5.Balancinghose

3.PortC

Filteringaclosed-loophydraulicsystemafteramajorcomponentfailure(e.g.,

transmissionpistonpumporwheelmotor)isnecessarytopreventunwanted

materialfromtransmittingthroughoutthesystem.Ifaclosed-loophydraulic

systemlteringtoolisnotusedtoensurethesystemcleanliness,repeatfailures,

aswellassubsequentdamagetootherhydrauliccomponentsintheaffected

system,willoccur.Toeffectivelyremovethecontaminationfromtheclosed-loop

tractioncircuit,usetheT orohighowhydrauliclterandhydraulichosekits

(refertoSpecialT ools(page4–27)).

1.Parkthemachineonalevelsurface,shutoftheengine,andremovethekey

fromthekeyswitch.

IMPORTANT

Beforeliftingthemachinewithajack,reviewandfollowJacking

Instructions(page1–7).

2.Liftandsupportthemachinesothatallthewheelsareofftheground.

Note:Ifthewheelmotorwasreplaced,installahigh-owltertotheinlet

ofthenewmotorinsteadoftothetransmission.Thiswillpreventsystem

contaminationfromenteringanddamagingthenewwheelmotor.

3.Cleantheareaaroundthetractioncircuithosesonthetopofthetransmission

(Figure61).Determinewhichpistonpumpcircuitistobeltered.

4.Disconnectthehydraulichosefromthetransmissionpumpinletttingforthe

pistonpumptobeltered(Figure61).

PistonPumptobeFilteredPumpInlet

RightsidepumpPortB

Leftsidepump

PortD

5.ConnecttheTorohighowhydrauliclterinseriesbetweenthepumpinlet

ttinganddisconnectedhose.Usethehydraulichosekit(refertoSpecial

Tools(page4–27))toconnecttheltertothemachine.Ensurethatthehose

connectionsareproperlytightened.

HydraulicSystem:ServiceandRepairs

Page4–72

Groundsmaster360

16225SLRevC

Loading...

Loading...