InstallingtheAirConditioningCompressor

g036833

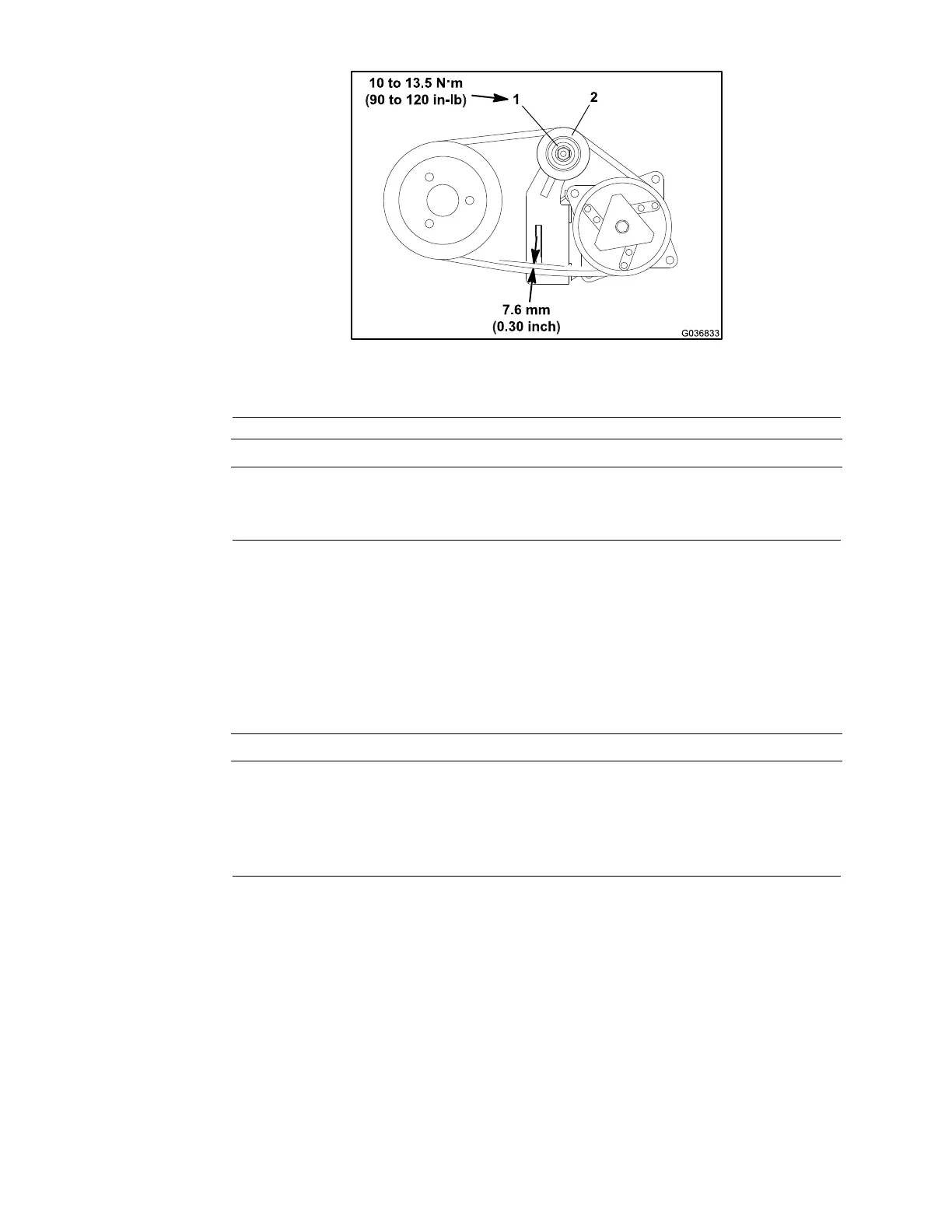

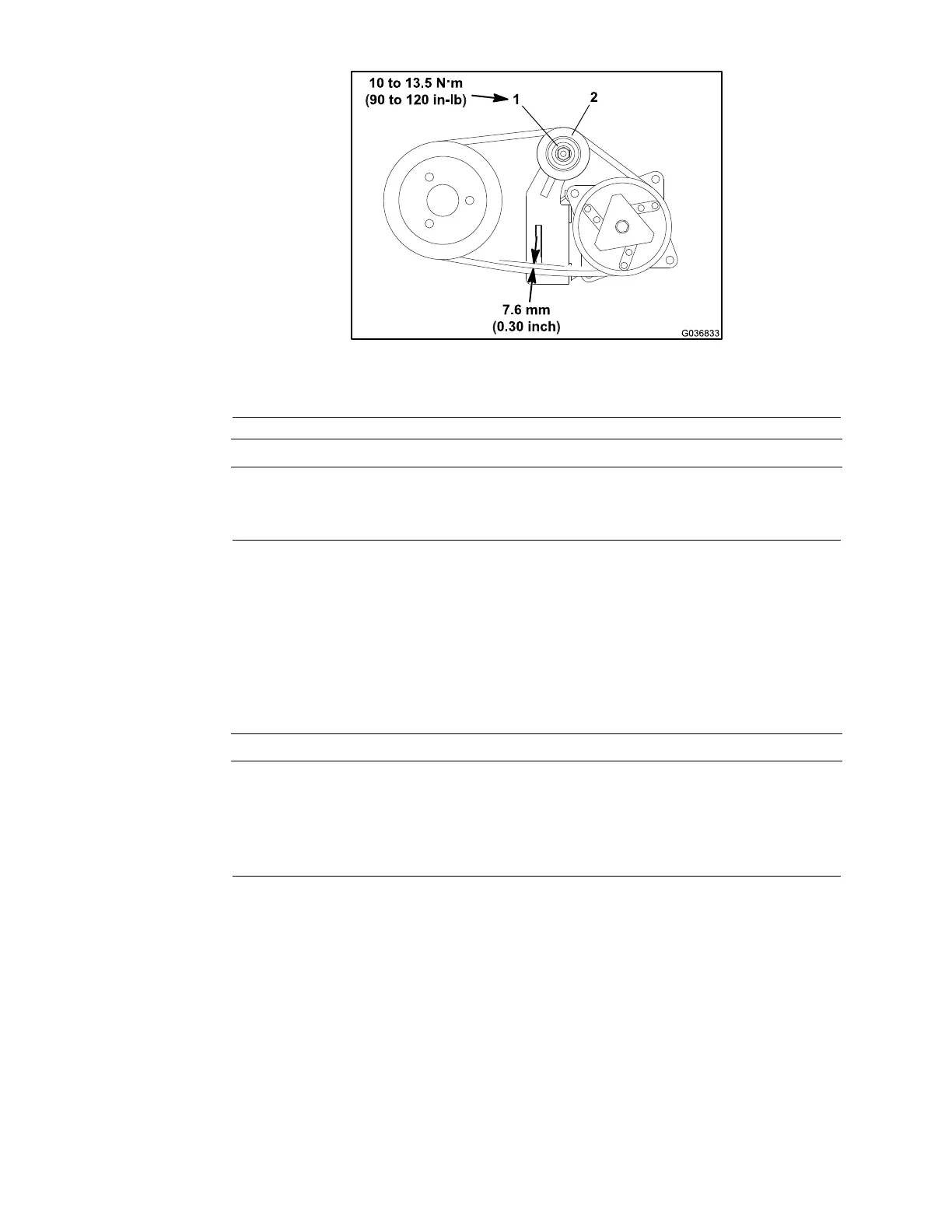

Figure320

1.Flangenut2.Idlerpulley

IMPORTANT

Thecompressormustbepositionedwiththelarger(suction)port

towardtheoutsideofthemachine.

1.Positionthecompressortothecompressormountonthemachineframe.

2.Ensurethattheclearancebetweenthecompressormountingangesand

compressorbracketislessthan0.10mm(0.004inch).Ifnecessary,install

shimsbetweenthecompressorangesandbrackettoadjustclearance.

3.Positionthecompressorwithsmallerrefrigerantportclosesttotheengine

andsecurethecompressortothecompressormountwiththe2screws(item

18inFigure319)and2locknuts.

IMPORTANT

Afterthecompressorisinstalled,ensurethatyourotatethe

compressordriveshaftseveraltimestocorrectlydistributetheoilin

thecompressor.Performthisproceduretopreventdamageofthe

compressorbecauseoftheoilslugging.

4.Manuallyrotatethecompressordriveshaftatleast10revolutionstoensure

thatthereisnocompressoroilinthecompressorcylinders.

5.Installtheairconditioningcompressordrivebelt.Adjustthedrivebelttension

untilthebeltdeectionis7.6mm(0.30inch)at10kg(22lb)forceapplied

halfwaybetweentheengineandcompressorpulleys,andtightenthenut

thatsecurestheidlerpulley(Figure320).

6.Removethecapsthatyouplacedonthehosesandttingsduringtheremoval

process.Usethelabelsthatyouattachedduringremovaltocorrectlyattach

thehosestothecompressor.Torquethedischargehosetting(smaller

tting)andsuctionhosetting(largertting)asshowninFigure319.

7.Connectthecompressorelectricalconnectortothemachinewireharness.

OperatorCab:ServiceandRepairs

Page8–8

Groundsmaster360

16225SLRevC

Loading...

Loading...