Workman HDX Auto Page 6 − 33 Electrical System

Battery Testing

1. If battery filler caps are removable, conduct a

hydrometer test of the battery electrolyte.

IMPORTANT: Make sure the area around the cells is

clean before opening the battery caps.

A. Measure the specific gravity of each cell with a

hydrometer. Draw electrolyte in and out of the

hydrometer barrel prior to taking a reading to warm−

up the hydrometer. At the same time take the temper-

ature of the cell.

B. Temperature correct each cell reading. For each

10F (6C) above 80F (27C) add 0.004 to the specific

gravity reading. For each 10F (6C) below 80

o

F (27C)

subtract 0.004 from the specific gravity reading.

Example: Cell Temperature 100F

Cell Specific Gravity 1.245

100F minus 80F equals 20F

(38C minus 27C equals 11C)

20F multiply by 0.004/10F equals 0.008

(11C multiply by 0.004/6C equals 0.008)

ADD (conversion above) 0.008

Correction to 80F (27C) 1.253

C. If the difference between the highest and lowest

cell specific gravity is 0.050 or greater or the lowest

cell specific gravity is less than 1.225, charge the bat-

tery. Charge at the recommended rate and time given

in Charging or until all cells specific gravity is 1.225

or greater with the difference in specific gravity be-

tween the highest and lowest cell less than 0.050. If

these charging conditions can not be met, replace

the battery.

2. Perform a high−discharge test with an adjustable

load tester.

This is one of the most reliable means of testing a battery

as it simulates the cold−cranking test. A commercial bat-

tery load tester is required to perform this test.

CAUTION

Follow the manufacturer’s instructions when us-

ing a battery load tester.

A. Check the voltage across the battery terminals

prior to testing the battery. If the voltage is less than

12.4 VDC, charge the battery.

B. If the battery has been charged, apply a 150 amp

load for fifteen (15) seconds to remove the surface

charge. Use a battery load tester following the

manufacturer’s instructions.

C. Make sure battery terminals are free of corrosion.

D. If battery filler caps are removable, measure the

temperature of the center cell.

E. Connect a battery load tester to the battery termi-

nals following the manufacturer’s instructions.

Connect a digital multimeter to the battery terminals.

F. Apply a test load of 270 amps (one half the Crank-

ing Performance rating of the battery) for fifteen (15)

seconds.

G. Take a battery voltage reading at fifteen (15) se-

conds, then remove the load.

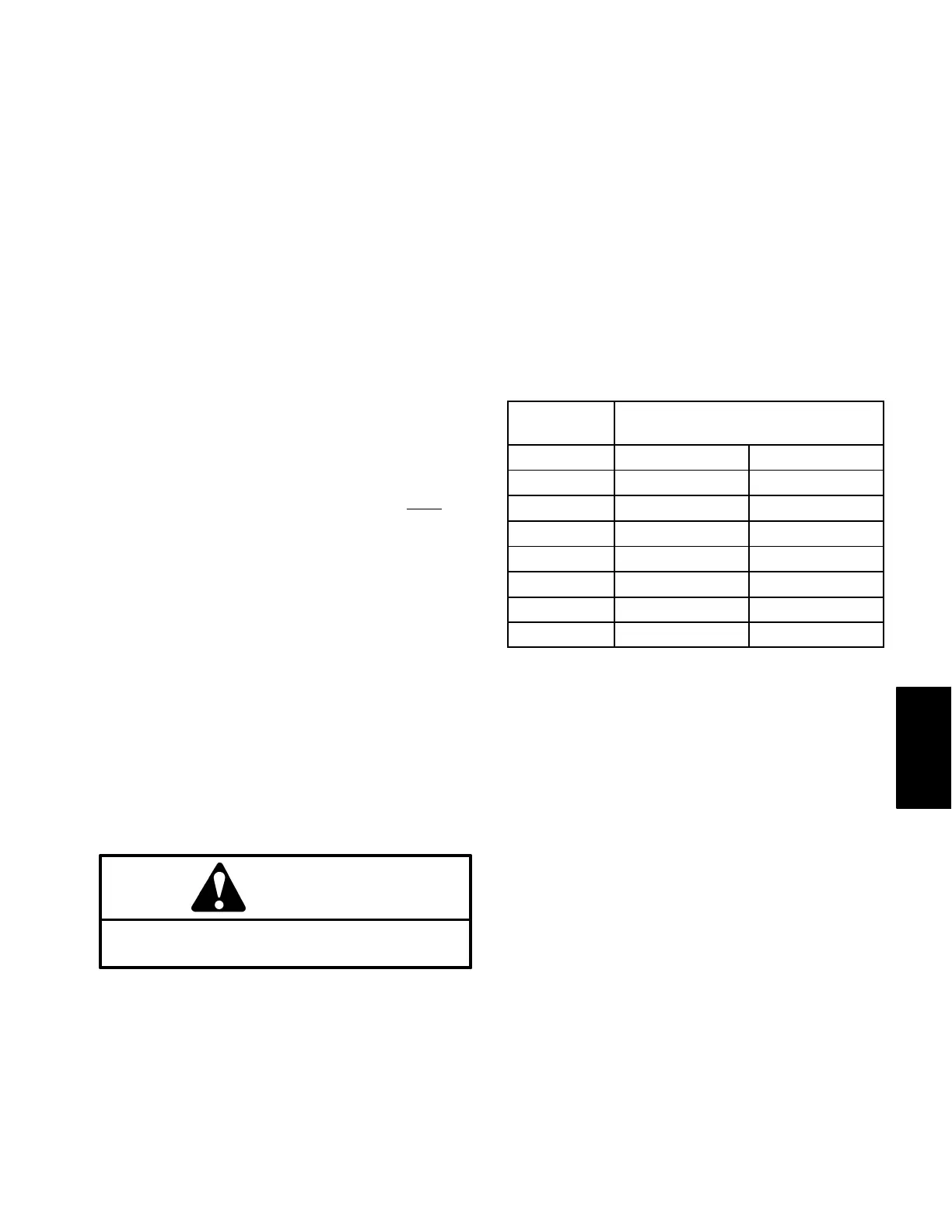

H. Using the table below, determine the minimum

voltage for the cell temperature reading.

Minimum

Voltage

Battery Electrolyte

Temperature

9.6 70F (and up) 21C (and up)

9.5 60F 16C

9.4 50F 10C

9.3 40F 4C

9.1 30F −1C

8.9 20F −7C

8.7 10F −12C

8.5 0F −18C

I. If the measured battery voltage is below the mini-

mum voltage shown in the table, replace the battery.

If the measured voltage is at or above the minimum

voltage shown in the table, return the battery to ser-

vice.

Electrical

System

Loading...

Loading...