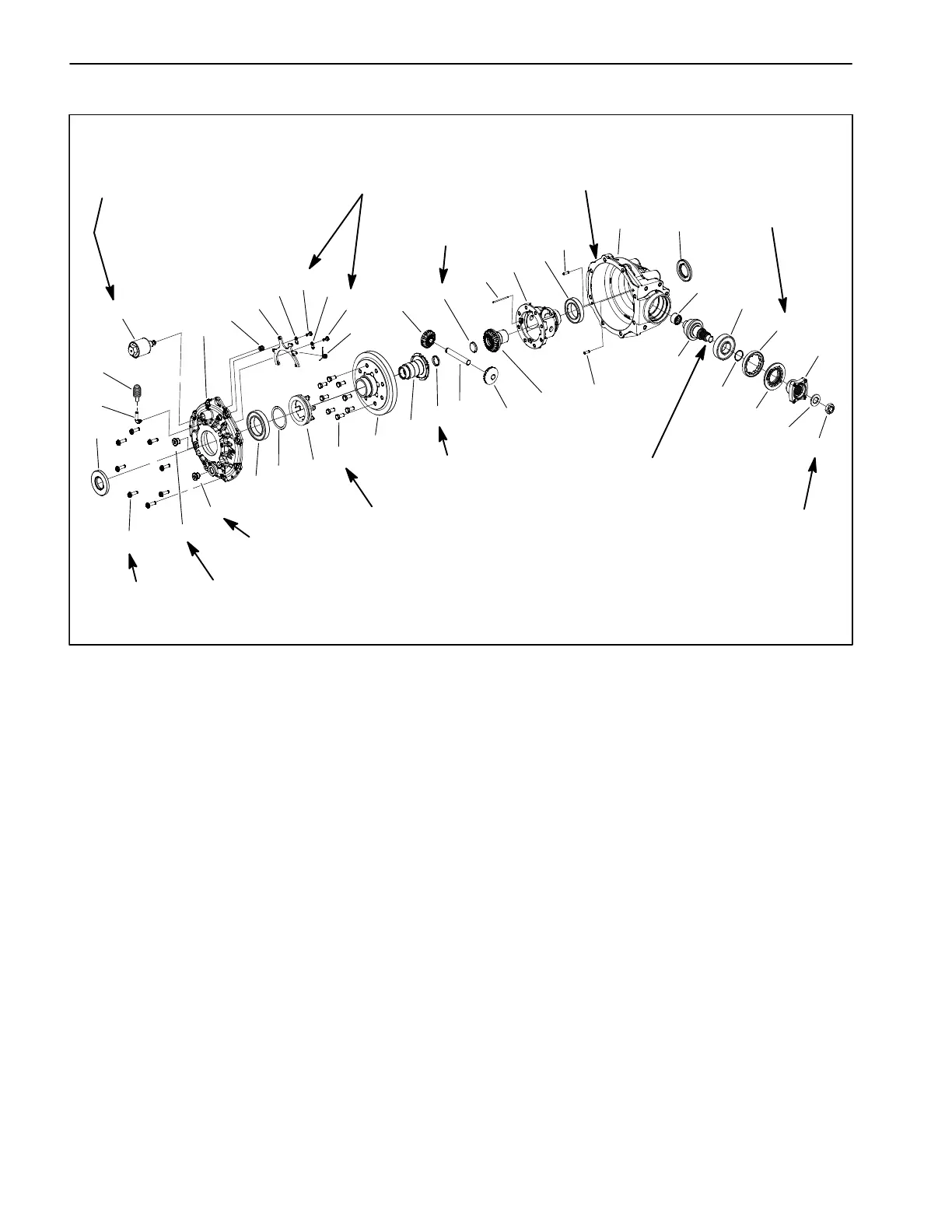

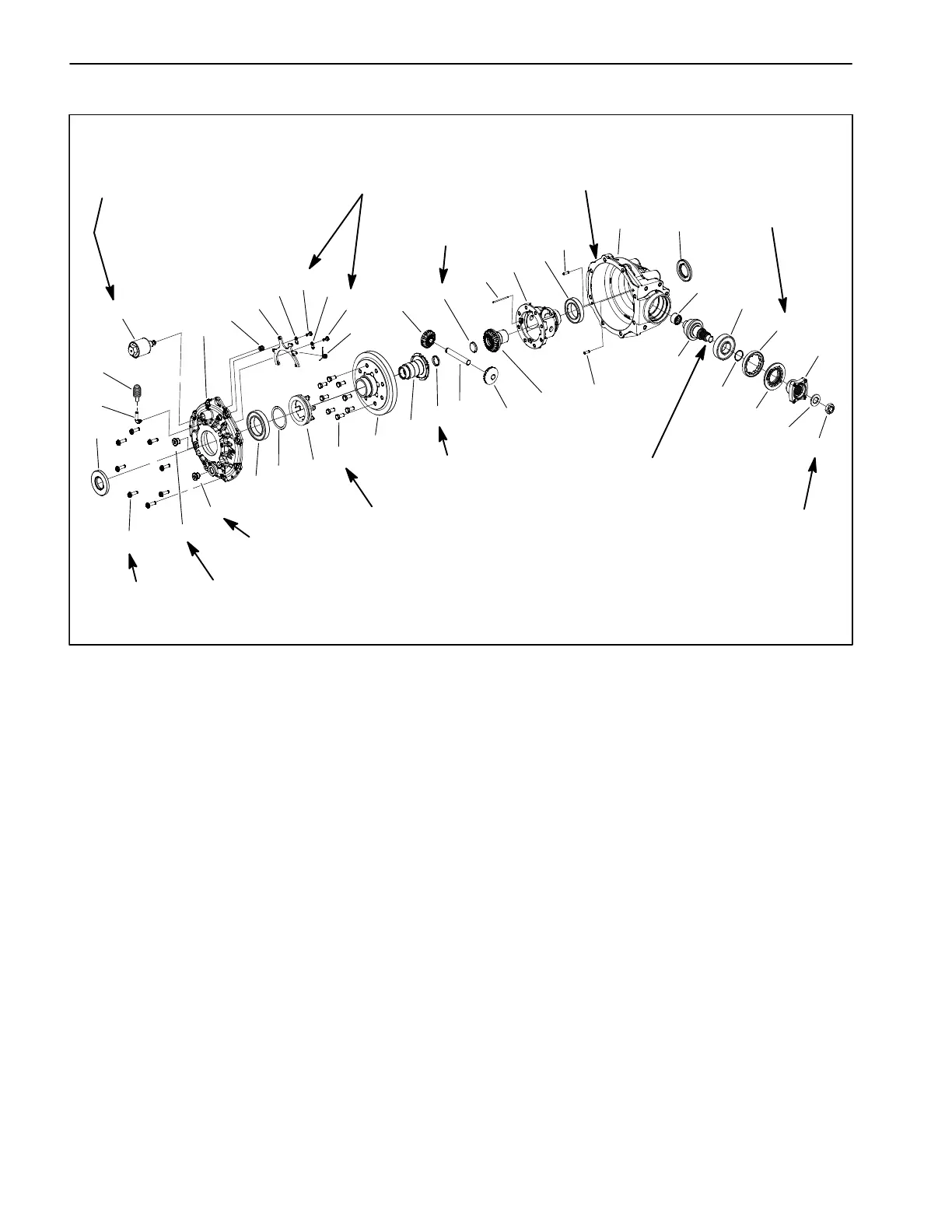

Workman HDX AutoPage 4 − 44Drive Train

Rear Differential Service

Figure 48

1. Fill plug

2. Engagement dog

3. Drain plug

4. Torx screw (2)

5. Flange head screw (8)

6. Vent tube

7. Hex nut

8. Lock washer set (2 halves)

9. Dowel pin (2)

10. Pinion gear

11. Shim

12. Lock collar

13. Ball bearing

14. Ball bearing

15. Caged needle bearing

16. Torsion return spring

17. Compression spring

18. Output cover

19. Gear case

20. Cap screw (8)

21. Spiral gear

22. Output gear

23. Output gear

24. Expansion plug (2)

25. Dowel pin

26. Differential gear pin

27. Differential pinion gear (2)

28. Differential housing

29. Ball bearing

30. Coupler

31. Fork retainer (2)

32. Shift fork

33. Solenoid

34. Seal

35. Seal

36. O−ring

37. Seal

38. Breather bellows

24

29

30

8

37

14

15

9

21

27

25

6

28

11

13

18

3

5

1

33

17

32

31

4

16

22

23

10

20

12

19

34

35

4

31

9

26

36

7

2

10 to 14 ft−lb

(14 to 19 N−m)

15 to 20 ft−lb

(21 to 27 N−m)

7 to 10 ft−lb

(9.5 to 13.5 N−m)

54 to 59 ft−lb

(74 to 80 N−m)

195 to 215 ft−lb

(265 to 291 N−m

490 to 510 ft−lb

(665 to 691 N−m)

20 ft−lb

(27 N−m)

10 to 14 ft−lb

Loctite #680

Loctite #680

38

(14 to 19 N−m)

24

27

Thread Locker

High Strength (Red)

Retaining Compound

Retaining Compound

Apply

Silicone Sealant

Rear Differential Disassembly (Fig. 48)

1. Clean the outside of the differential assembly.

2. Remove the solenoid (item 33) from the differential

cover. Then, remove compression spring (item 17) from

cover.

3. Support the differential assembly with the output cov-

er side facing up.

4. Remove the eight (8) flange head screws that secure

the output cover (item 18) to the gear case.

IMPORTANT: Do not use a pry bar or screw driver on

the differential output cover and gear case mating

surfaces when separating the cover from the gear

case. Damage to the sealing surfaces of the compo-

nents may result.

5. Using pry point areas as shown in Figure 49, carefully

separate the output cover from the gear case and then

remove the output cover. Locate and retrieve the shim

(item 11) and engagement dog (item 2).

6. For assembly purposes, note location of dowel pins

(item 9) in the cases. Remove pins to prevent them from

falling out unexpectedly.

Loading...

Loading...