Workman HDX Auto

Page 3 − 5

Kohler Gasoline Engine

Service and Repairs

Accelerator Control

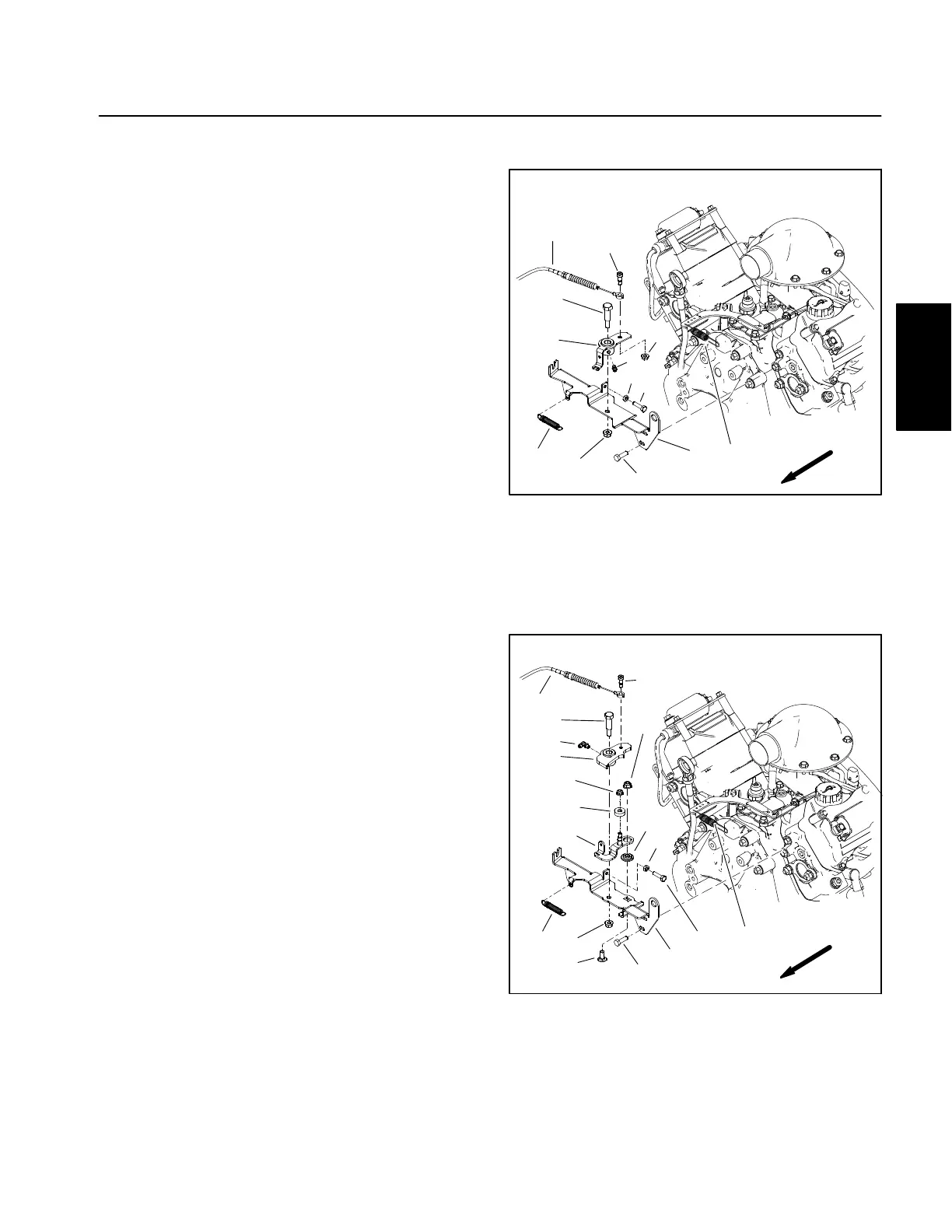

Two styles of accelerator control have been used on

Workman HDX Auto machines. On vehicles with serial

numbers below 315000000 (Fig. 4), the accelerator

control includes a bellcrank that is rotated by the accel-

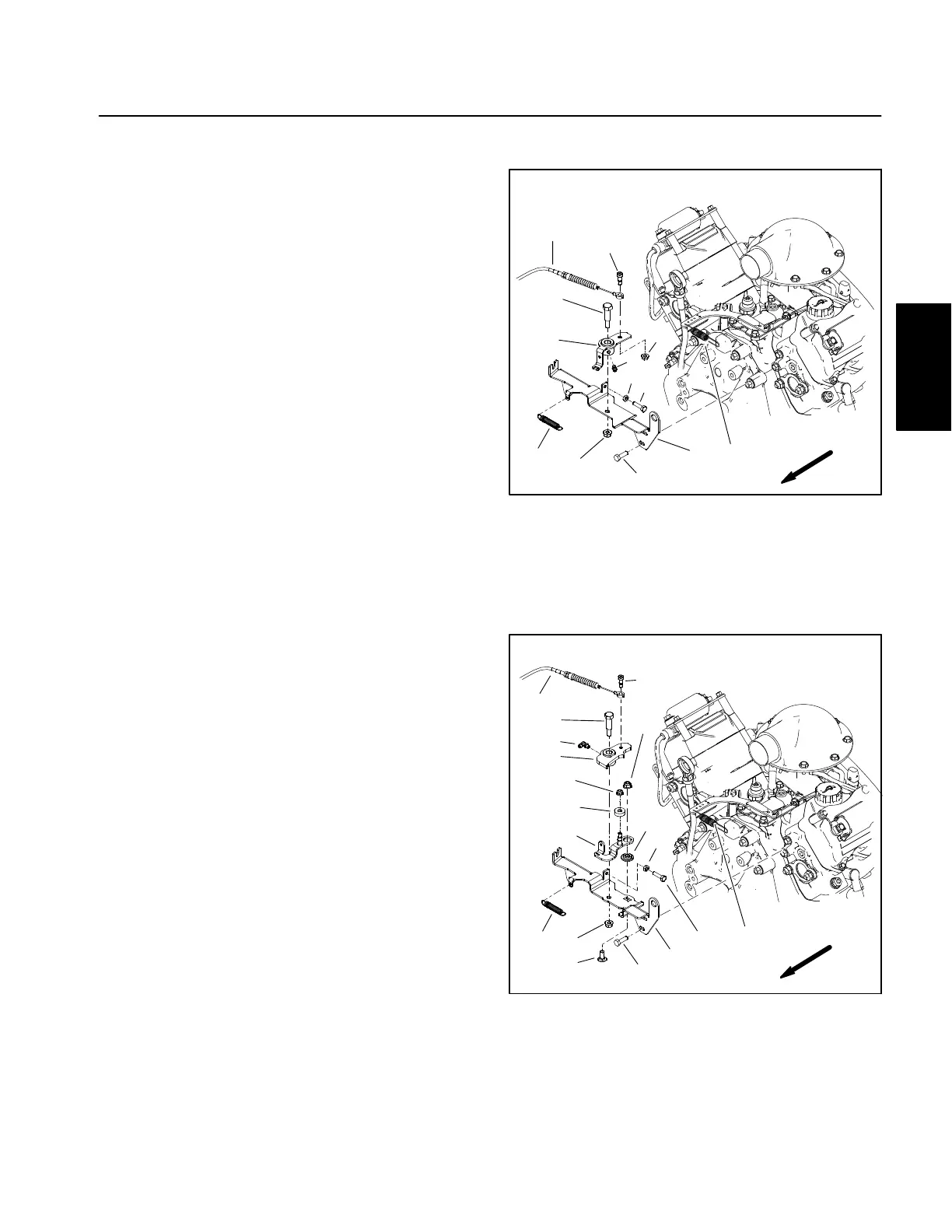

erator cable to change engine speed. Vehicles with seri-

al numbers above 315000000 (Fig. 5) use an

accelerator control with additional components.

Disassembly (Fig. 4 or 5)

1. Park vehicle on a level surface and engage parking

brake.

2. Raise or remove the cargo bed or other attach-

ment(s). If bed is raised, place safety support on lift cylin-

der.

3. Make sure that the engine is stopped and the key is

removed from ignition switch. Allow engine to cool.

4. Remove accelerator control components as needed

using Figure 4 or 5 as a guide. If engine governor spring

needs to be disconnected from bellcrank, note attach-

ment points for assembly purposes.

Assembly (Fig. 4 or 5)

1. Install removed accelerator control components to

engine using Figure 4 or 5 as a guide.

2. On vehicles with serial numbers above 315000000

(Fig. 5), make sure that ball bearing (item 15 in Fig. 5)

is lightly contacting bellcrank. If necessary, loosen

flange nut (item 5 in Fig. 5) and move throttle lever until

ball bearing is in light contact with bellcrank. Tighten nut

after adjustment.

3. Make sure that the engine governor spring is at the

end of the slot in the bellcrank (item 3 in Fig. 4) or throttle

lever (item 12 in Fig. 5) without being tensioned. If the

governor spring is tensioned, the engine throttle will not

be closed when the accelerator pedal is released.

4. After assembly is completed, make sure that bell-

crank moves freely as accelerator pedal is depressed

fully and released.

5. Lubricate grease fitting on bellcrank.

6. Check adjustment of accelerator control (see Adjust

Accelerator Control in the Adjustments section of this

chapter).

7. Lower or install cargo bed or attachment(s).

1

2

3

4

5

6

7

8

9

10

11

12

12

Figure 4

1. Throttle bracket

2. Cap screw (4)

3. Bellcrank

4. Shoulder screw

5. Flange nut

6. Grease fitting

7. Accelerator cable

8. Shoulder bolt

9. Flange nut

10. Jam nut

11. Cap screw

12. Governor spring

FRONT

SERIAL NUMBER BELOW 315000000

Figure 5

1. Throttle bracket

2. Cap screw (4)

3. Bellcrank

4. Shoulder screw

5. Flange nut (2)

6. Grease fitting

7. Accelerator cable

8. Shoulder bolt

9. Jam nut

10. Cap screw

11. Extension spring

12. Throttle lever

13. Carriage screw

14. Idler bushing

15. Ball bearing

16. Flange nut

17. Governor spring

15

2

3

4

5

6

7

8

9

10

11

12

16

13

14

1

5

FRONT

17

SERIAL NUMBER ABOVE 315000000

Gasoline Engine

Kohler

Loading...

Loading...