Workman HDX Auto Page 7 − 59 Hydraulic System

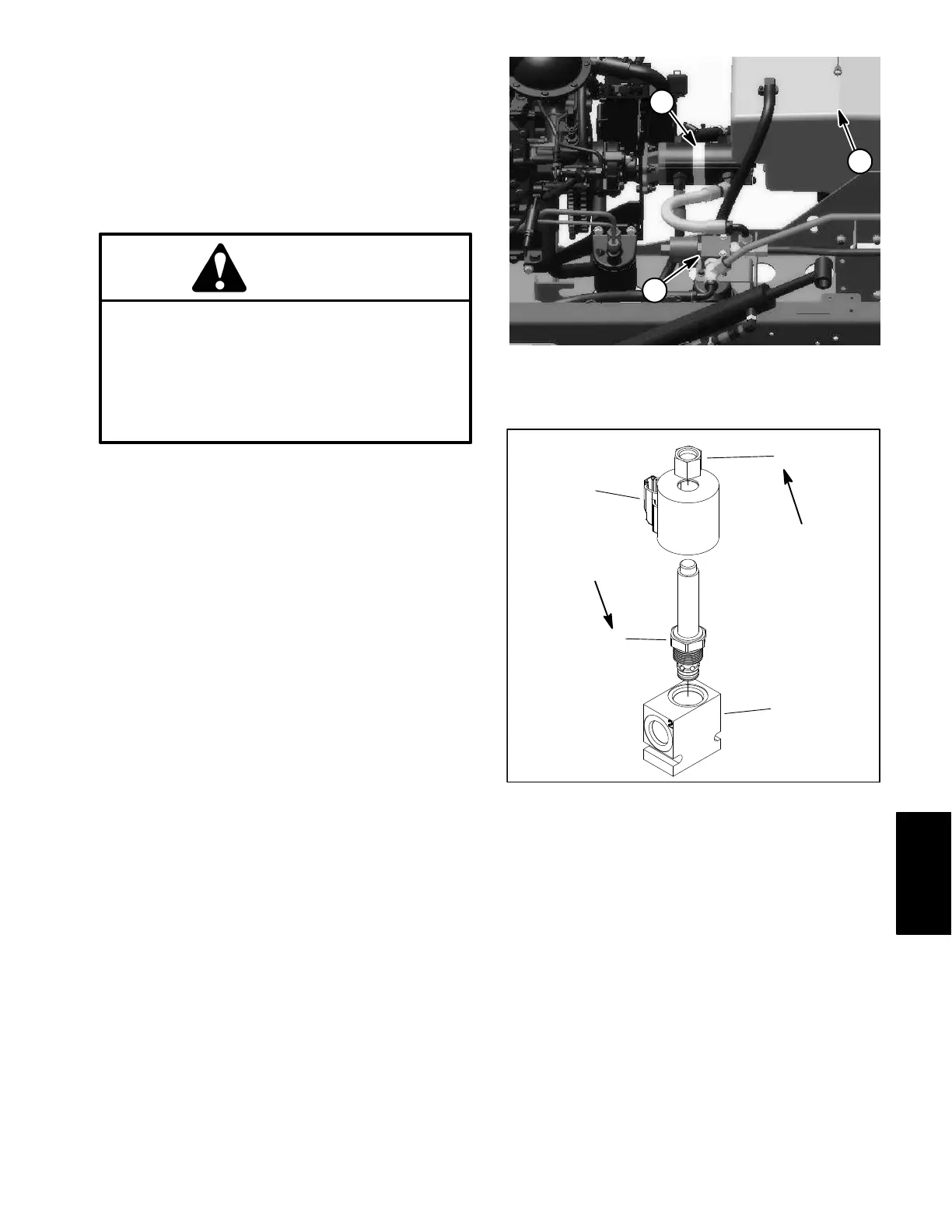

Removal (Fig. 46)

1. Park vehicle on a level surface, raise and support

cargo bed (if installed), shut engine off and engage the

parking brake. Remove key from the ignition switch.

2. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

CAUTION

Before performing any service or repair on hy-

draulic system components, relieve system

pressure to avoid injury from pressurized hy-

draulic oil. Stop the engine, remove key from the

ignition switch, rotate the steering wheel in both

directions, lower or support the bed and operate

other hydraulic accessories.

3. Label and disconnect hydraulic hoses and tubes at

hydraulic manifold. Install caps or plugs in open hoses,

tubes and fittings to prevent contamination and leakage

of hydraulic oil.

4. Remove manifold from vehicle using Figure 46 as a

guide.

5. If hydraulic tee fittings are to be removed from man-

ifold, mark fitting orientation to allow correct assembly.

Remove fittings from manifold and discard O−rings.

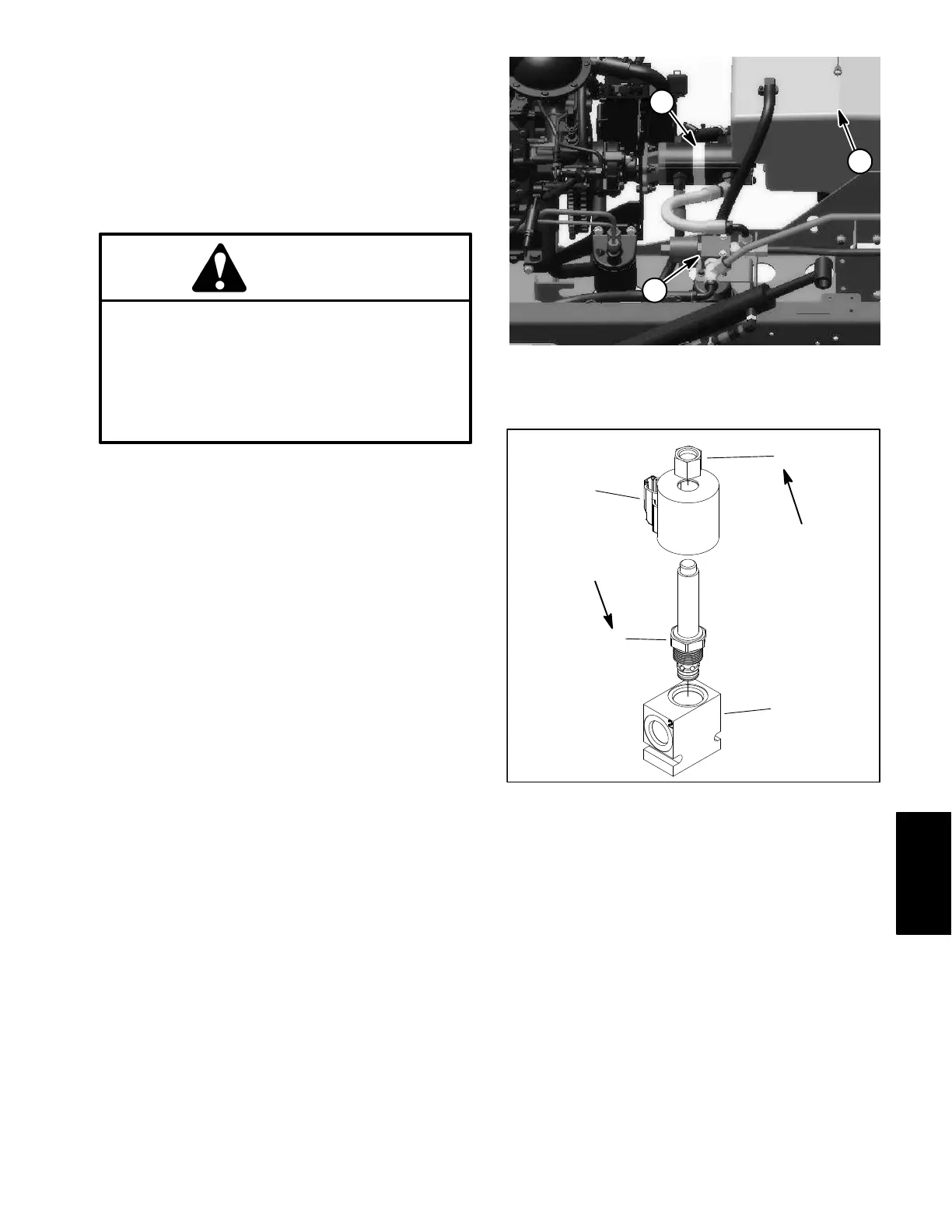

Valve Cartridge Service (Fig. 46)

1. Make sure the entire outer surface of the manifold is

clean before removing the cartridge valve.

2. Remove nut securing solenoid coil to the cartridge

valve. Carefully slide solenoid off the valve.

IMPORTANT: Use care when handling the valve car-

tridge. Slight bending or distortion of the stem tube

can cause binding and malfunction.

3. Remove cartridge valve with a deep socket wrench.

Note correct location of O−rings, sealing rings and back-

up rings on valve. Remove and discard seal compo-

nents.

4. Visually inspect the port in the manifold for damage

to the sealing surfaces, damaged threads or contamina-

tion.

1. Hydraulic reservoir

2. Gear pump

3. Hydraulic manifold

Figure 47

2

1

3

1. Nut

2. Solenoid coil

3. Solenoid cartridge valv

4. Manifold body

Figure 48

1

2

3

4

5 ft−lb

(6.8 N−m)

25 ft−lb

(34 N−m)

5. Visually inspect cartridge valve for damaged sealing

surfaces and contamination.

A. Contamination may cause valves to stick or hang

up. Contamination can become lodged in small valve

orifices or seal areas causing malfunction.

B. If valve sealing surfaces appear pitted or dam-

aged, the hydraulic system may be overheating or

there may be water in the system.

Hydraulic

System

Loading...

Loading...