14

wallaceperimetersecurity.comPhone: 866.300.1110

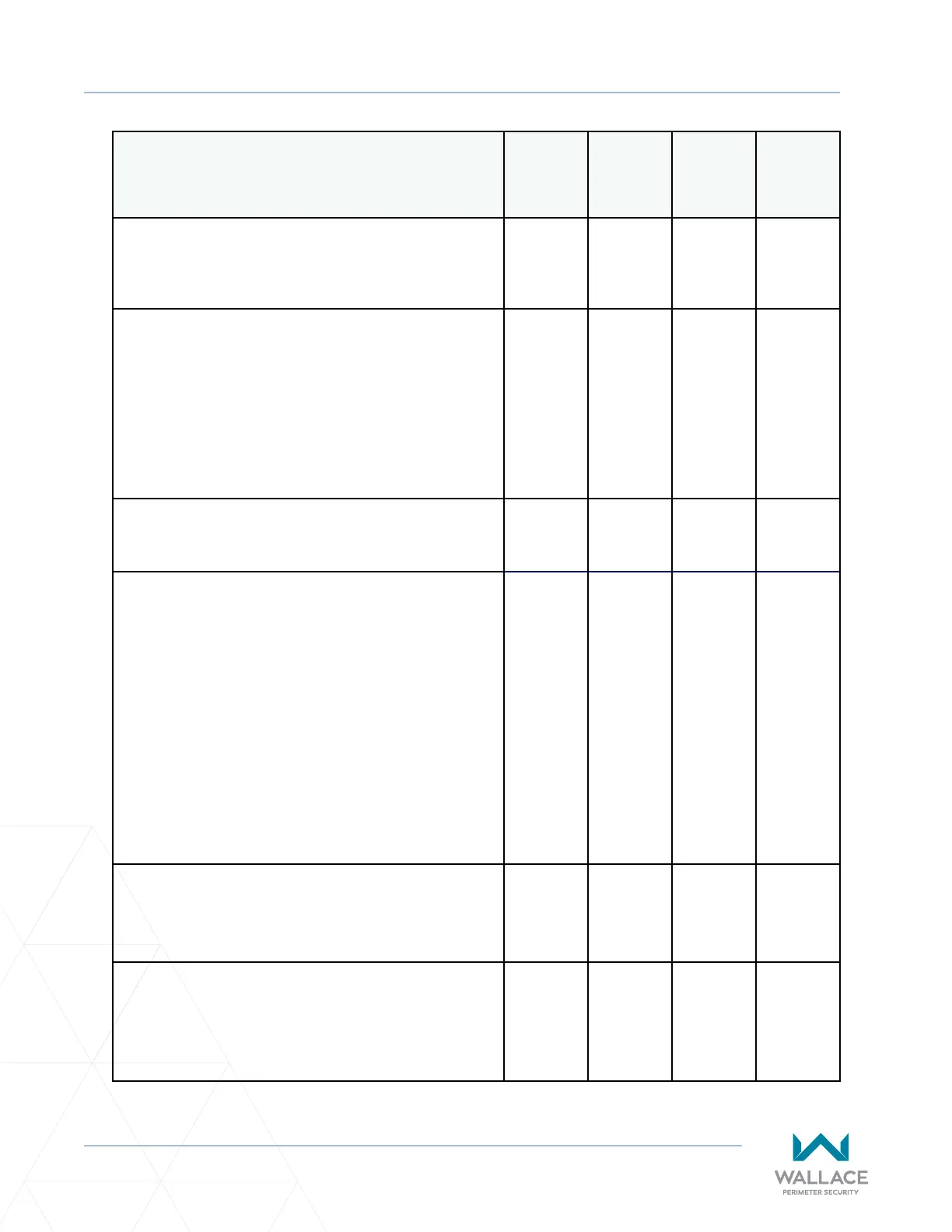

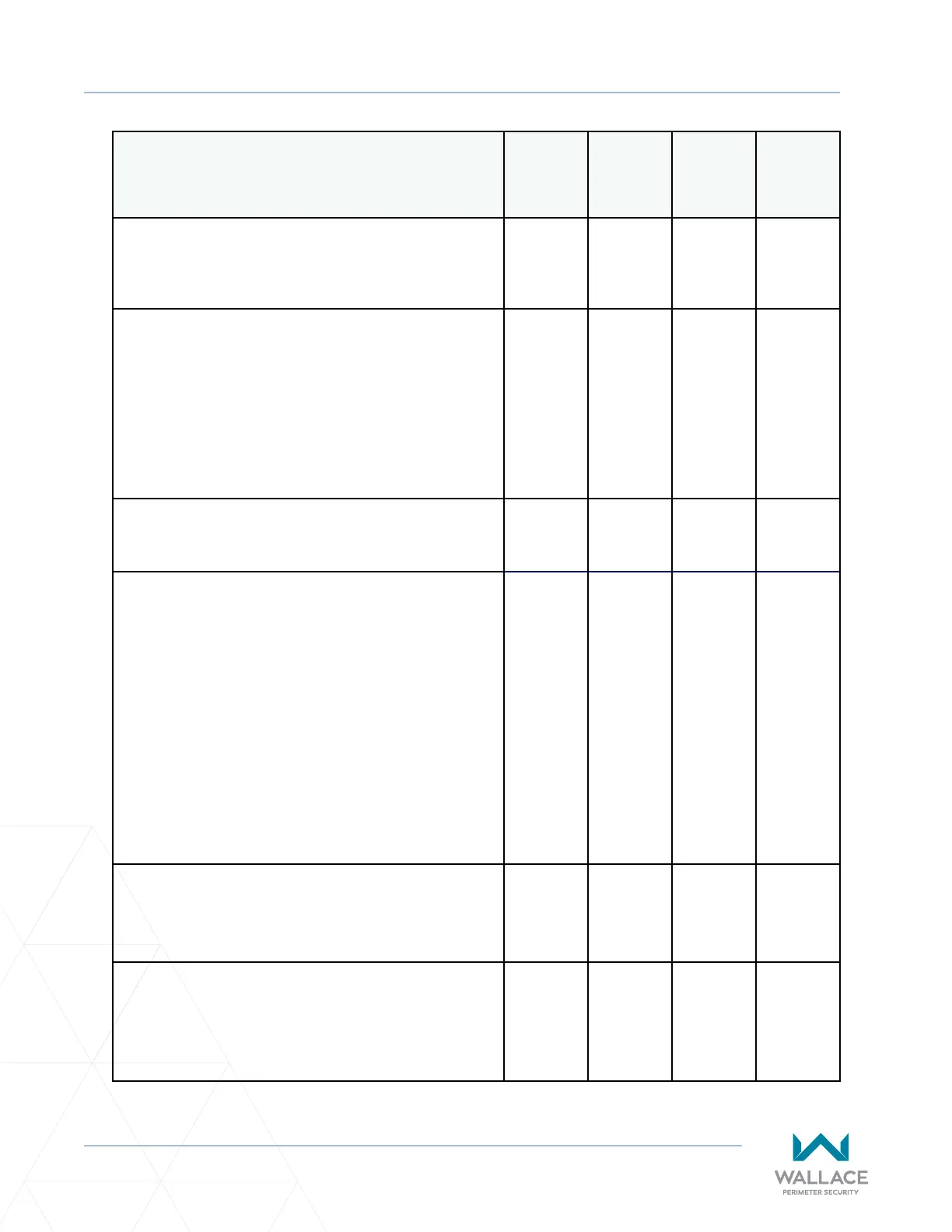

ALPHA/DELTA INSTALLATION & MAINTENANCE CHECKLIST

ALPHA/DELTA INSTALLATION AND MAINTENANCE

CHECKLIST

Checked Good Needs

Aenon

N/A

5� Top Rollers

Check top guide rollers for wear. Top rollers should

be replaced every 3 to 5 years depending on usage.

6� Leading/Trailing Edge Post

Pull on or twist the leading and trailing edge posts

by hand to make sure that they do not move – all

fasteners should be ght. Also, make sure that the

leading edge post foot is secure (boom of leading

edge post). If loose, use self-drilling screws to

hold in place. Locte should be used to secure the

fasteners holding the posts in place.

7� Gate Portals

Ensure gate portals are in line and level.

8� Operator

When mounng the operator cabinet, the right

height is very crical. If mounted too high, the

gate leaf will put extreme pressure on the gearbox,

therefore the teeth on the gear will wear out very

quickly and cause internal damage to the gearbox.

If mounted too low, the teeth on the drive gear

will not engage the tooth rack appropriately. The

operator must be installed parallel to the gate

beam; drive gear must run true in the middle of

the tooth rack throughout the length of travel. The

opmum gap is 2.7mm (0.106 inch) – roughly the

diameter of an 11-gauge e wire.

9� Drive Sprocket

Check the drive sprocket. Worn or broken teeth

will require replacement.

10� Drive Belt

Check drive belt for cracks and tooth wear. Either

condion will require the belt to be replaced. The

belt should be replaced every 2 years.

Loading...

Loading...