Step9:

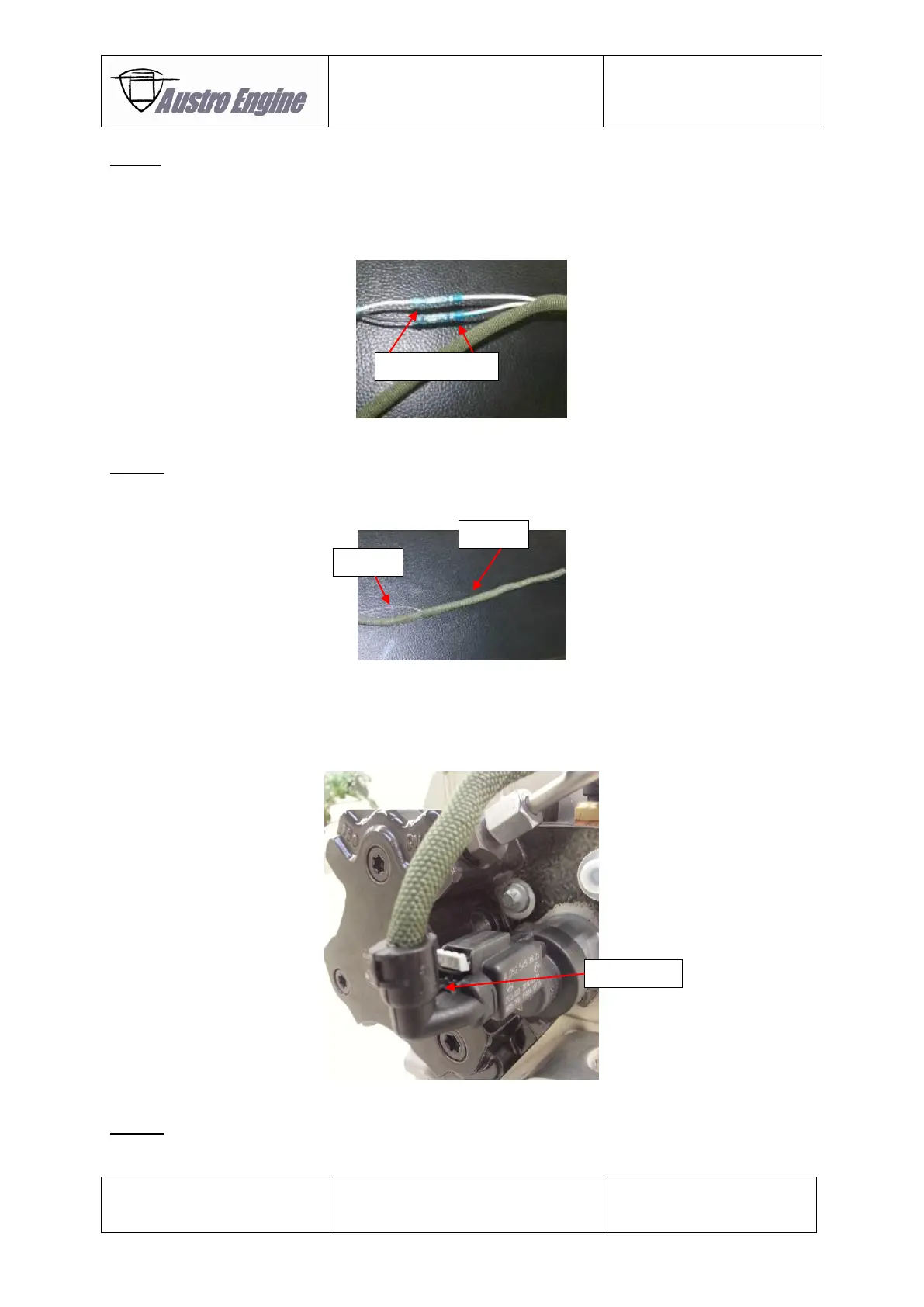

Put the blue isolation sleeve of the inline crimp D-436-37 directly over the splice crimp.

Heat the inline crimp isolation sleeve (300°C – 350°C) with a “hot air gun” until the inline crimp

isolation seals the inline crimp barrel and the single wires.

Step10:

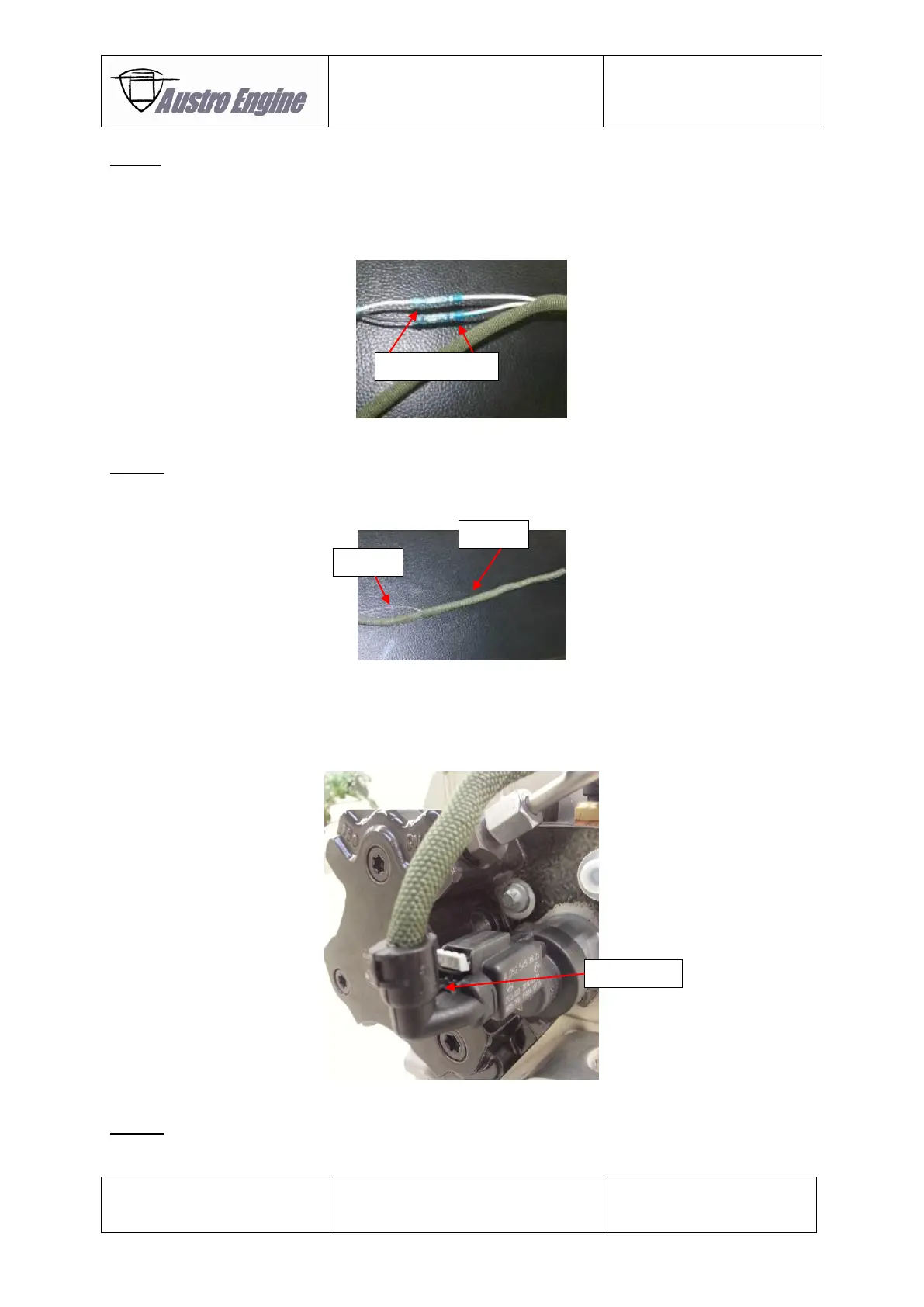

Put the chafing protection ROUNDIT 2000NX5-5 over the repair kit cable and the engine harness. The

length of the chafing protection ROUNDIT 2000NX5-5 can be reduced as necessary.

Ensure that the pig tail is not covered by the ROUNDIT. The connector shall be connected to FMU unit

as stated below. Ensure that the black plastic backshell has the correct position as stated in the

picture below.

Step11:

Use cable ties PLT1M-M30 and PLT4S-M30 for fixation of repair kit cable as required.

Loading...

Loading...