109

ELECTRICAL AND IGNITION

FLYWHEEL AND STATOR SERVICING

6

FLYWHEEL AND STATOR

SERVICING

IMPORTANT: Weak flywheel mag nets can

cause lo w alternator output and af fect outboard

performance. Weak flywheel magnets ca n also

cause low read ings on ignition test equipme nt,

such as a pe ak-reading voltmeter , which might

cause unnecessary parts replacement.

An accurate test o f alternat or ou tput can he lp

determine the flywh eel’s co ndition. Refer to

CHARGING SYSTEM TESTS on p. 97.

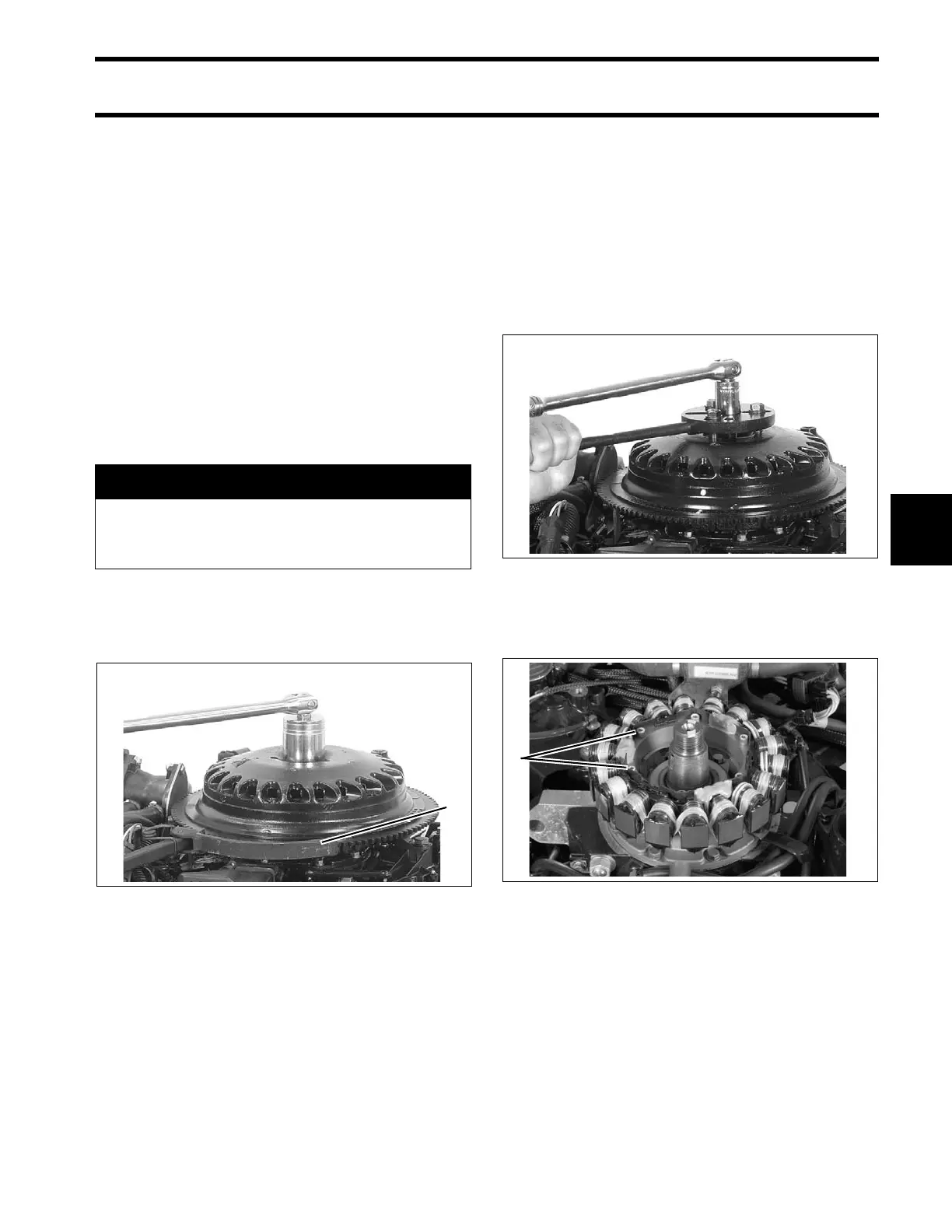

Flywheel Removal

Use Flywh eel Holder, P/N 771311, or equivalent,

and a 1 7/16 in. so cket to remo ve flywheel nut.

Discard flywheel nut.

Assemble the following components from Univer-

sal Puller Set, P/N 378103:

• Body, P/N 307636

• Screw, P/N 307637

• Handle, P/N 307638

• Three screws P/N 309492

• Three washers, P/N 307640

Apply Moly Lube grease to th e thre ads of th e

puller pressing screw, P/N 307637, and the center

hole of the crankshaft.

Place the puller on flywheel with body flat side up.

Attach the puller b ody with the th ree should er

screws and washers. Hold p uller bod y with ha n-

dle, and tighten pressing screw un til flywhee l

releases. T urn the center screw an d lif t t he fly-

wheel off of the crankshaft.

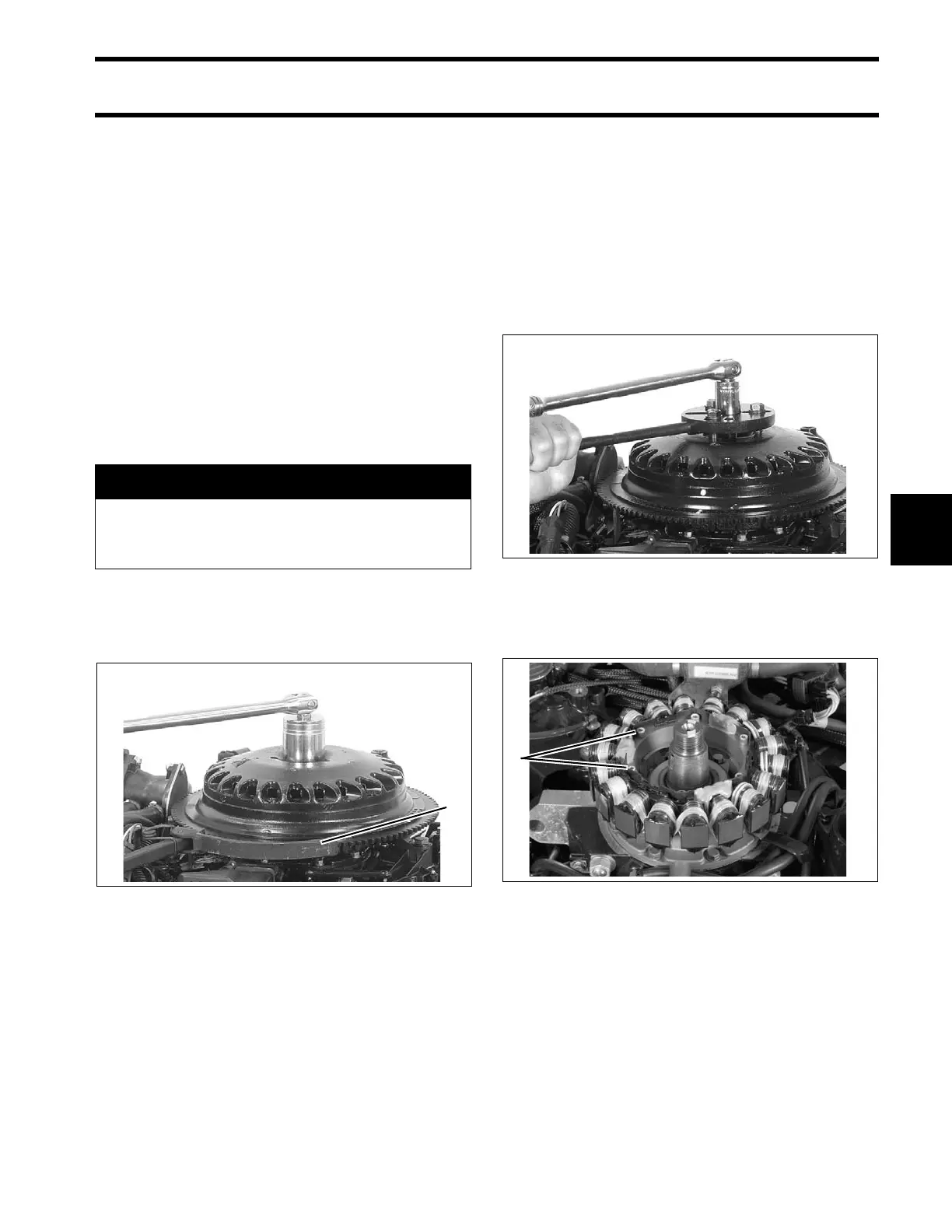

Stator Service

Remove six allen head screws to remove stator.

To install stator, position stator on cylinder block.

Apply Nut Lock to screw threads. Inst all scre ws

and tighten in crossing pattern to a torque of 24 to

36 in. lbs. (3 to 4 N·m).

A WARNING

To preve nt accid ental s tarting while s er-

vicing, discon nect battery cable s at the

battery.

1. Flywheel holder 000774

000772

1. Stator screws 006864

Loading...

Loading...