270

MIDSECTION

EXHAUST HOUSING SERVICE

Loosen and remove the upper mount plate screws

and remove the mount plate.

Lubricate the up per mount with soapy water and

pry up to remove it from the adapter housing.

Lift the a dapter/inner exhaust housing o ut of the

exhaust housing.

.

Cleaning and Inspection

Clean all parts with parts cleaning solvent and dry

with comp ressed air . All nut a nd screw threads

coated with thread locking material must be thor-

oughly cle aned b efore assembly . When u sing a

thread locking pro duct, be su re to prime t he

threads with Locquic Primer.

Examine the upper and lower thrust mounts, and

replace if deteriorated or damaged.

Before checking the ex haust housing fo r distor-

tion, thoroughly clean the top and bottom mating

surfaces and remove all sealer and corrosion.

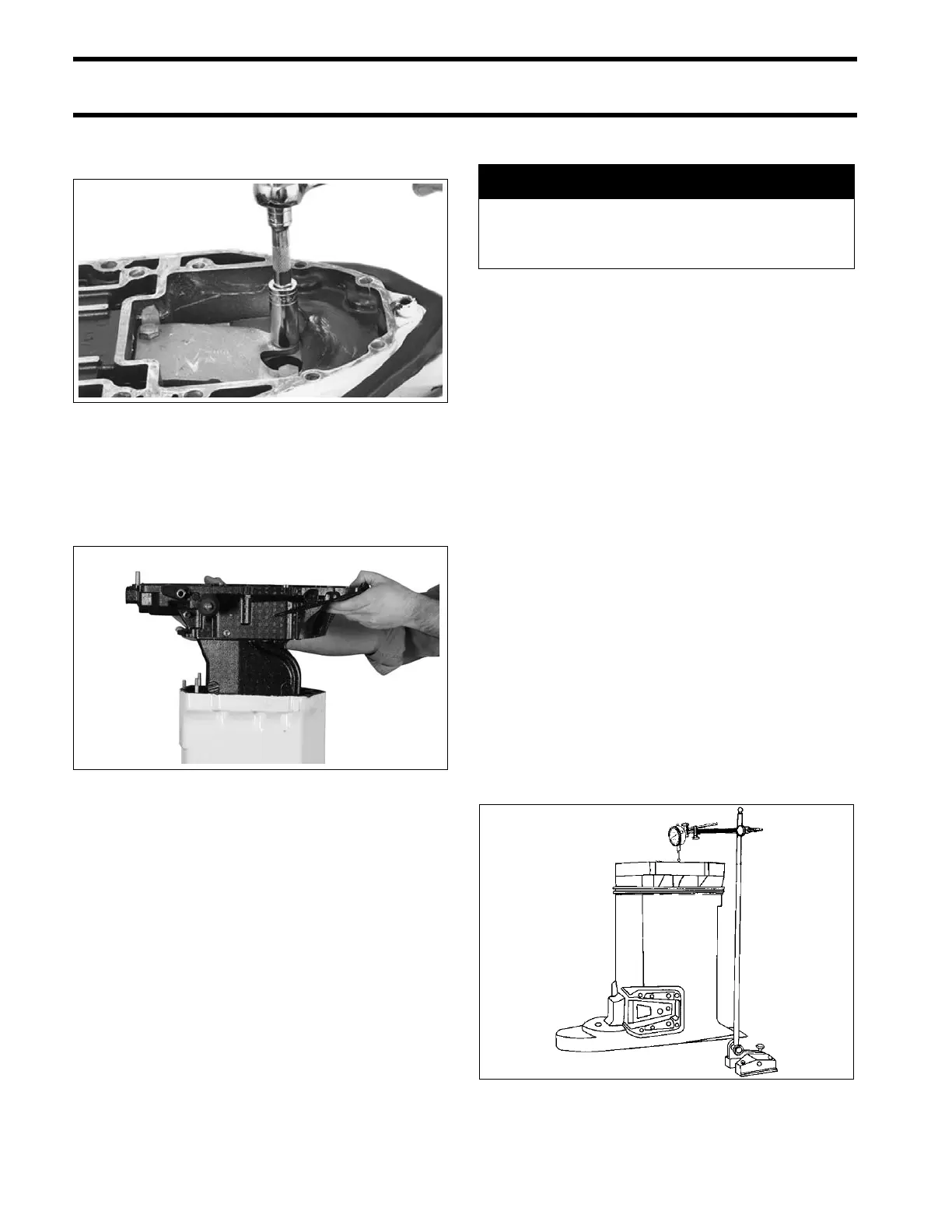

Check the e xhaust hou sing for distortio n. Place

the housing on a surface plate. Using a dial indi-

cator, check flatness by measuring the run-out on

the top edge of housing. The maximum allowable

run-out is 0.009 in. (0.228 mm). If you do not have

access to a dial indicator and surface plate, seek

the services of a machine shop. DO NOT attempt

to straighten a distorted housing. Replace it.

IMPORTANT: A d istorted exhaust ho using will

cause the upper driveshaft splines to wear exces-

sively and will damage the crankshaft splines.

32588

006981

A WARNING

Wear safety glasse s to avoid personal

injury, and set compressed air to less than

25 psi (172 kPa).

DR2223

Loading...

Loading...