140

FUEL SYSTEM

FUEL SYSTEM TESTS

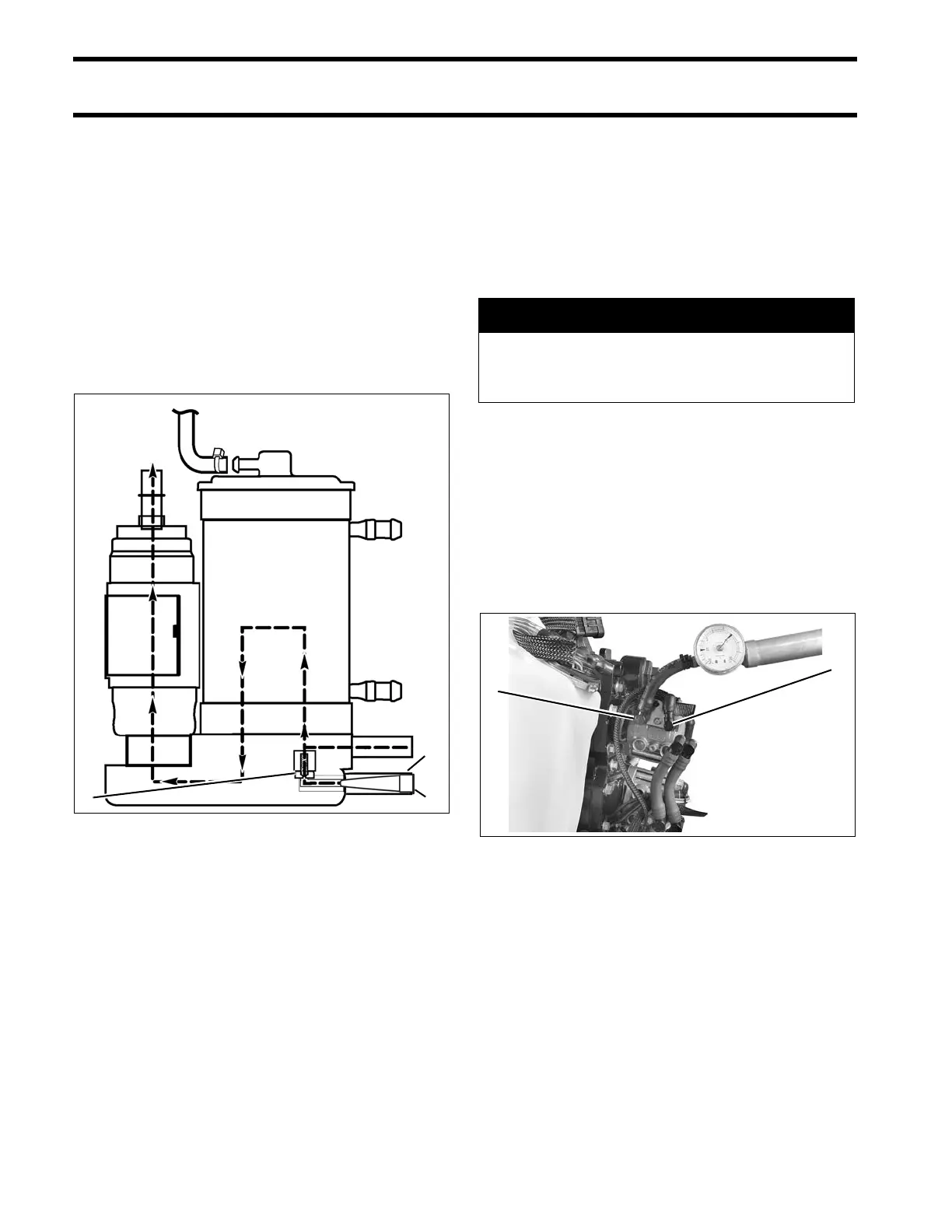

Pressure Regulator Test

Refer to Vapor Sep arator Service on p. 146 to

remove vapor separator.

Make su re filter is no t clogg ed. Clean or r eplace

as needed.

Apply oil to valve and connect pressure pump and

hose to the fuel return fitting of vapor separator.

Apply pressure to ch eck regulator ope ration. The

pressure sh ould open check valve at a pproxi-

mately 15 psi (103 kPa).

Vapor Separator Vent Check

Monitor the vapor separator vent hose. No fuel or

a trace of fuel is accep table. Exce ssive fuel dis-

charge indicates a vapor separator vent malfunc-

tion. Monitor vent f or presence of fuel during

testing. Temporarily install cle ar tubing for mon i-

toring. Replace vapor sep arator if th e ve nting of

fuel is continuous.

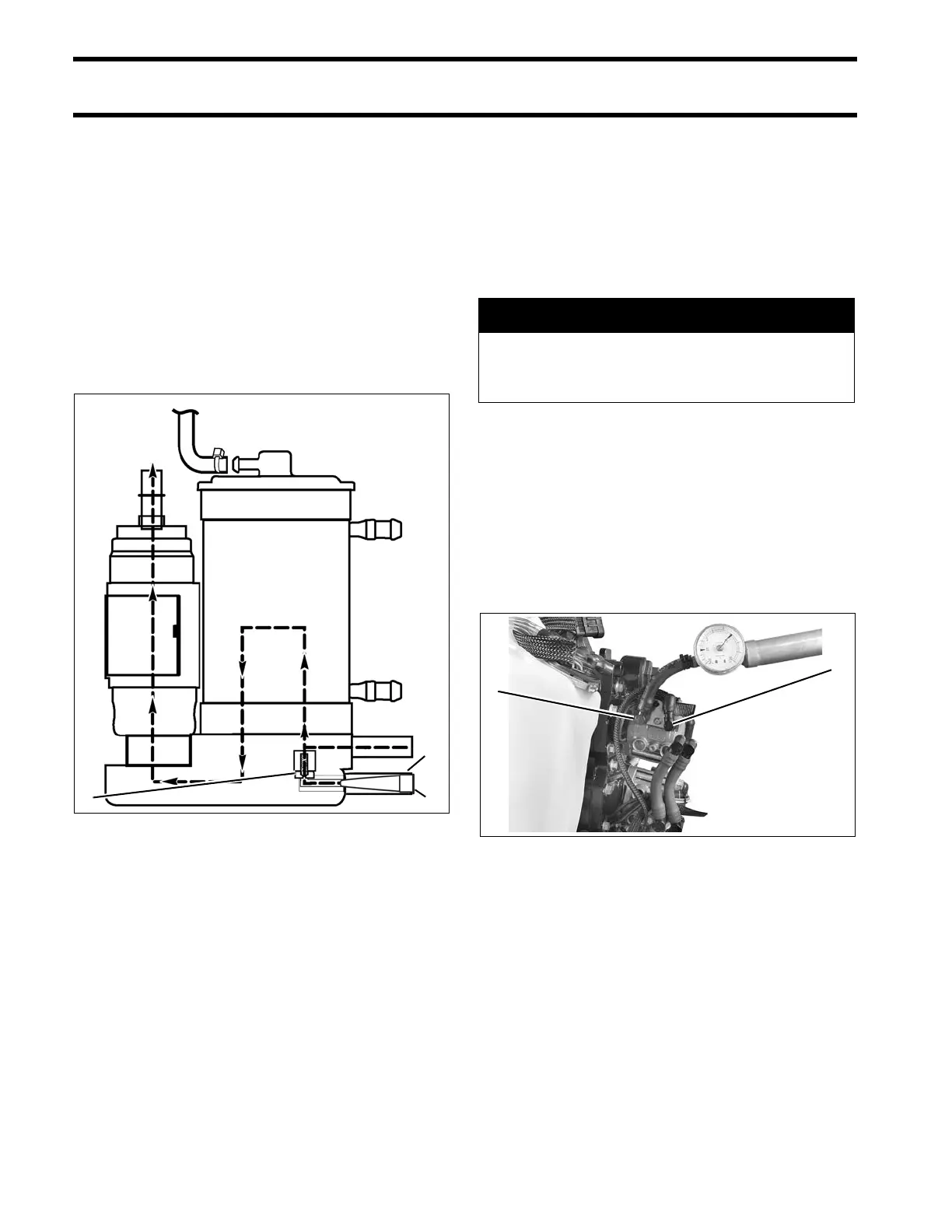

Fuel Injector Pressure Test

This te st re quires Inj ector T est Fi tting ki t,

P/N 5005844.

Disconnect the battery cables at the battery.

Relieve fuel system pressure. See Relieving Fuel

System Pressure on p. 143.

IMPORTANT: Perform test with in jector

mounted to cylinde r h ead and fittin gs installed

with manifold retainer.

Use cap and tie strap to seal off outlet fitting. Con-

nect a 0 to 30 psi (0 to 207 kPa) pressure tester to

the inlet fitting . Pressurize the inje ctor to 30 psi

(207 kPa). Pressure must h old f or at least five

minutes.

Refer to FUEL DE LIVERY TESTS on p. 85 for

additional test procedures.

1. Filter

2. Fuel return fitting

3. Pressure regulator

000249

A WARNING

Protect aga inst hazardous fuel s pray.

Before st arting any fuel syste m service,

carefully relieve fuel system pressure.

1. Outlet fitting

2. Inlet fitting

002379

Loading...

Loading...