238

POWERHEAD

POWERHEAD ASSEMBLY

Crankcase Assembly

Thoroughly clean an d deg rease the mating

flanges of the crankcase and cylinder block with a

non-petroleum based so lvent, such as iso propyl

alcohol or acetone, and let air dry.

IMPORTANT: DO NOT allow solvent to get on

internal componen ts. Clean on ly th e mating

flanges.

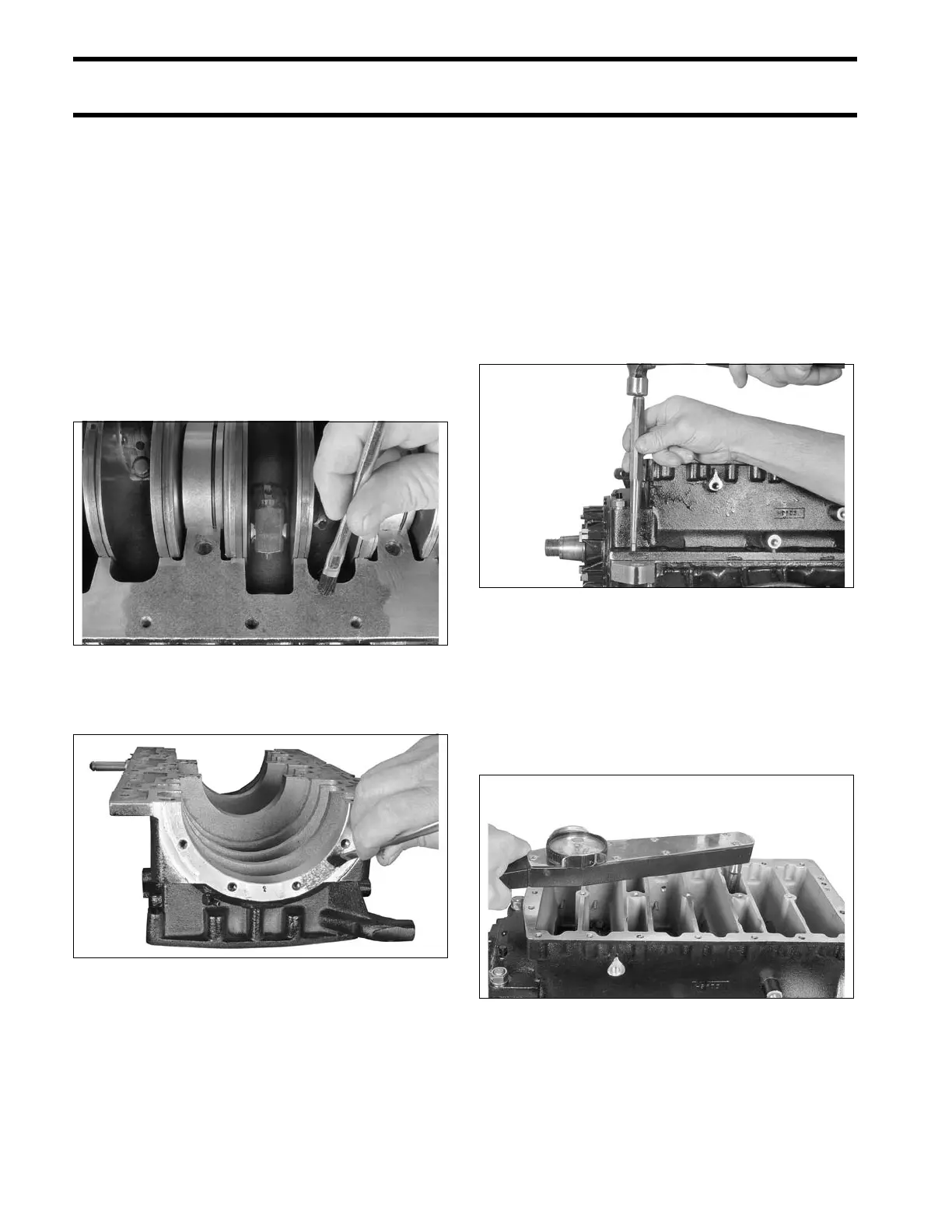

Use a small brush with a tapping motion to apply a

thin, even coat of Gel-Seal II sealant to the crank-

case mating fla nge. Th e sea ler must no t come

within 1/4 in. (6.4 mm) of bearings.

Lightly coat th e upper and lower crankcase head

flange surfaces with a thin layer of Gel-Seal II.

IMPORTANT: Gel-Seal II h as a shelf life of at

least one year when stored at roo m temperature.

Test the Gel-Seal II or replace it if the age of the

tube cannot be determined. Using old Gel-Seal II

could cause crankcase air leaks.

IMPORTANT: The use of Locquic Primer is NOT

recommended. If primer is used, crankcase

halves must be assemble d an d tig htened within

ten minutes after the Gel-Seal II has been applied.

Lower the crankcase into place.

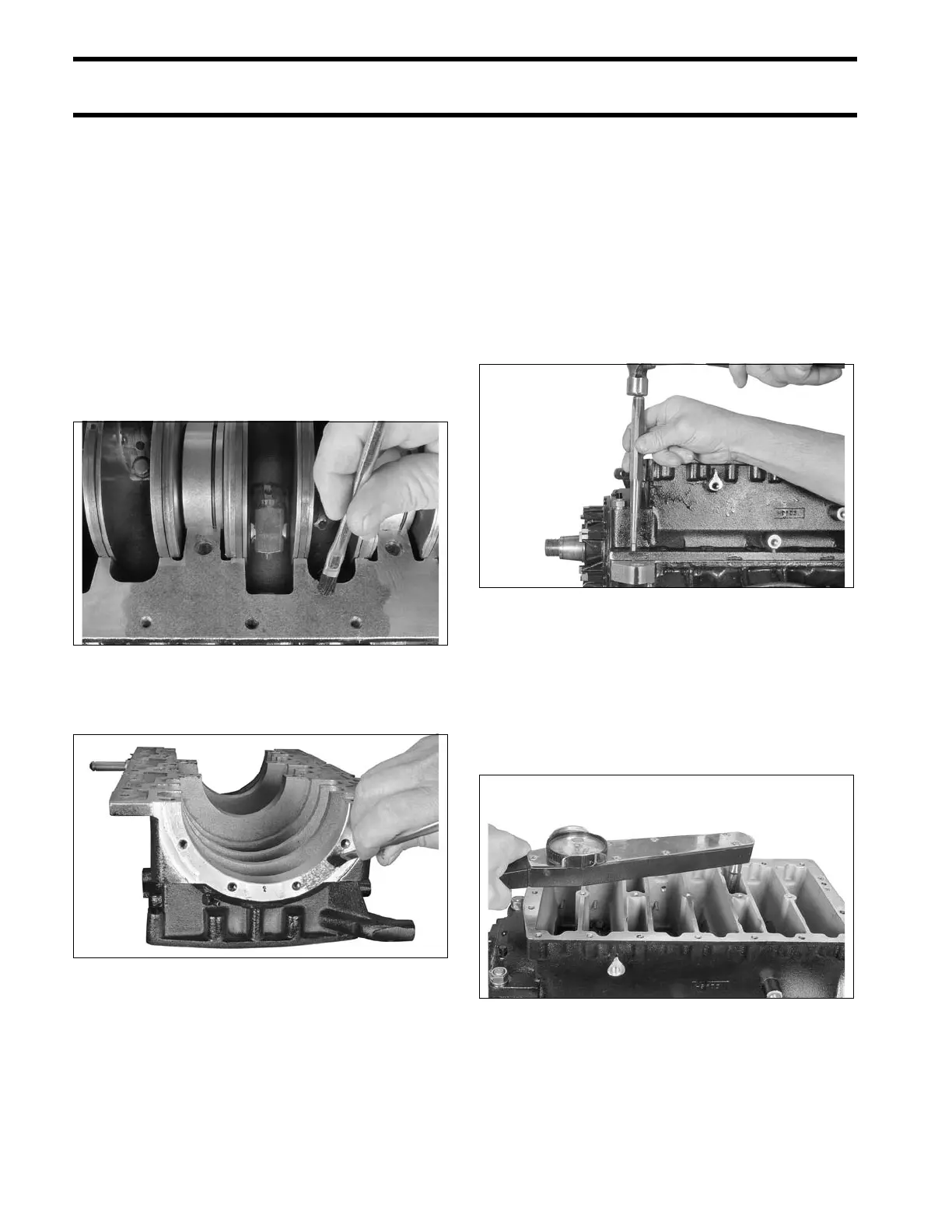

Install main bearing screws an d nuts finger tight,

no more than 60 in. lbs. (7 N·m).

When the crankcase is se ated, inst all and firmly

seat both crankcase taper pins.

Tighten main bearing screws a nd nuts in stages

to a final torque of:

• Screws – 48 to 53 ft. lbs. (65 to 72 N·m)

• Nuts – 38 to 42 ft. lbs. (52 to 57 N·m)

Start in the center an d work outward in a spira l

pattern.

004127

004134

004135

004141

Loading...

Loading...