110

ELECTRICAL AND IGNITION

FLYWHEEL AND STATOR SERVICING

Flywheel Installation

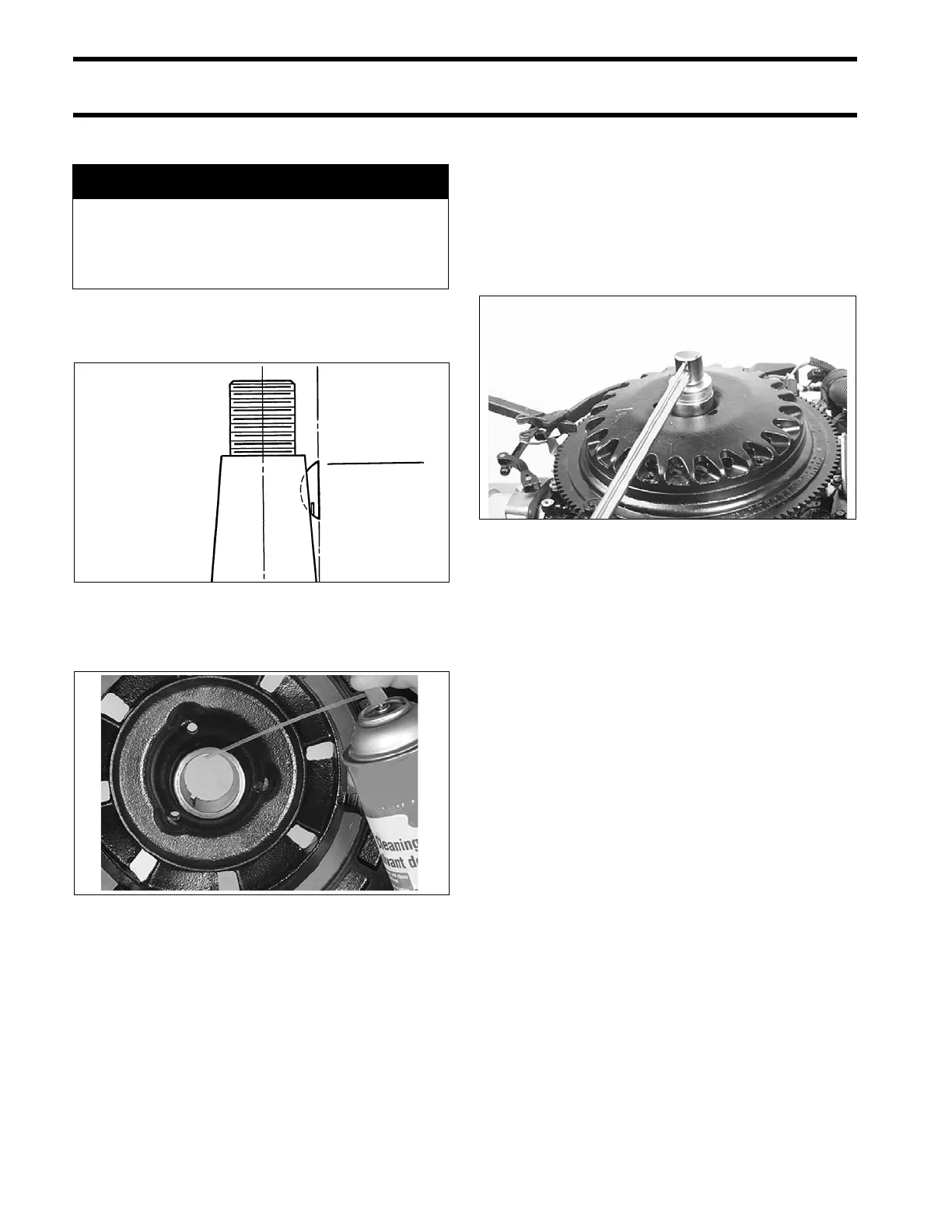

Install the outer edge of flywheel key parallel with

centerline of crankshaft.

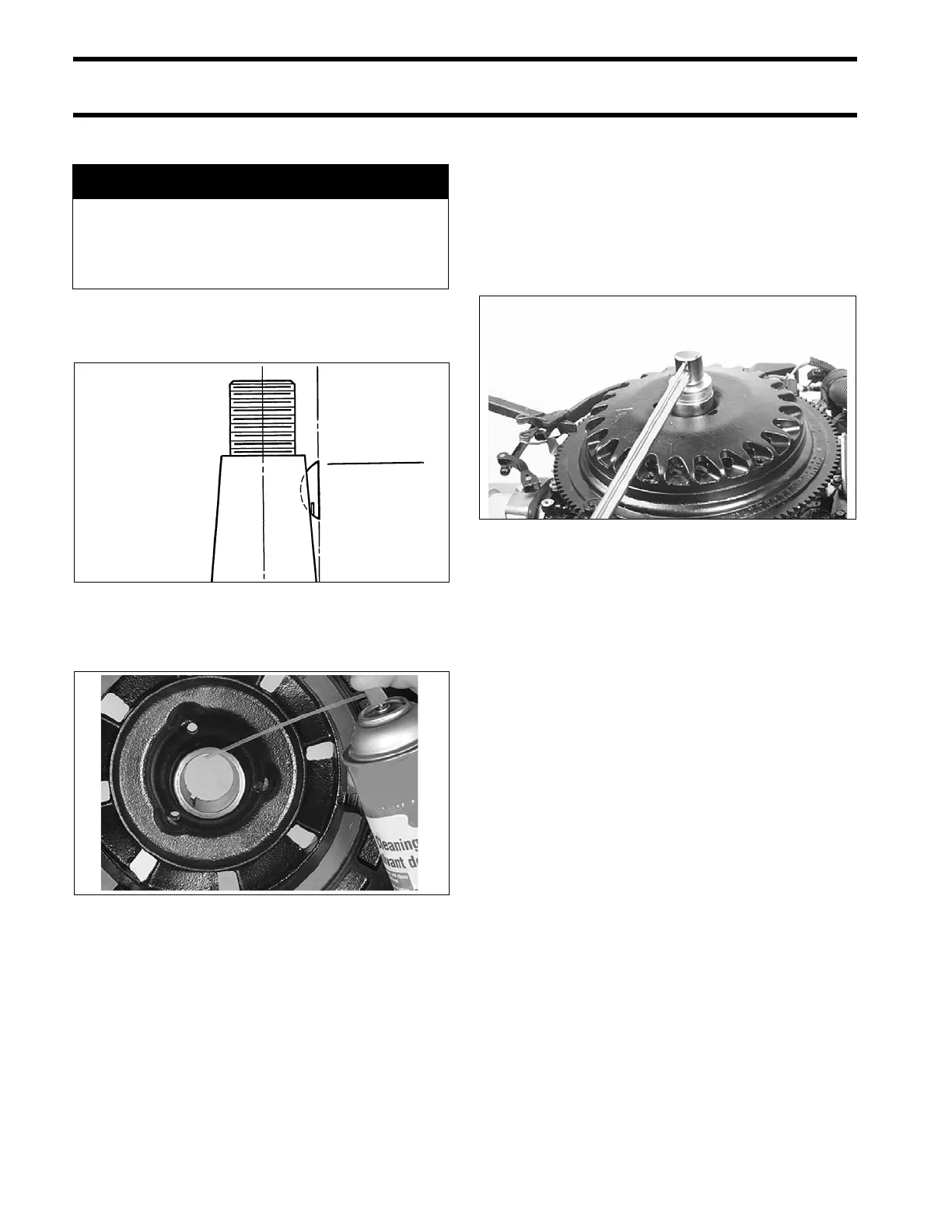

Thoroughly clean t he crankshaf t and f lywheel

tapers with Cleaning Solvent and let dry.

Apply a thin, even coa t of Nut Lock to the inside

taper of the flywheel.

IMPORTANT: DO NOT over apply Nut Lock on

flywheel t aper. This pr events Nut Lock from

migrating into upper seal of crankshaft.

Align the flywheel keyway and install the flywheel.

Coat the threads of the flywheel nut with Gasket

Sealing Compound. Install the nut and tighten to a

torque of 140 to 160 ft. lbs. (190 to 217 N·m).

IMPORTANT: Perform the timing ve rification

procedure after flywheel removal or replacement.

Refer to TIMING ADJUSTMENTS on p. 112.

A CAUTION

To avoi d injury , keep han ds and finge rs

clear from underside of flywheel. Flywheel

can snap toward stator with great magnetic

force.

1. Flywheel key DRC2116

49623

DP0567

Loading...

Loading...