118

ELECTRICAL AND IGNITION

ELECTRIC STARTER SERVICING

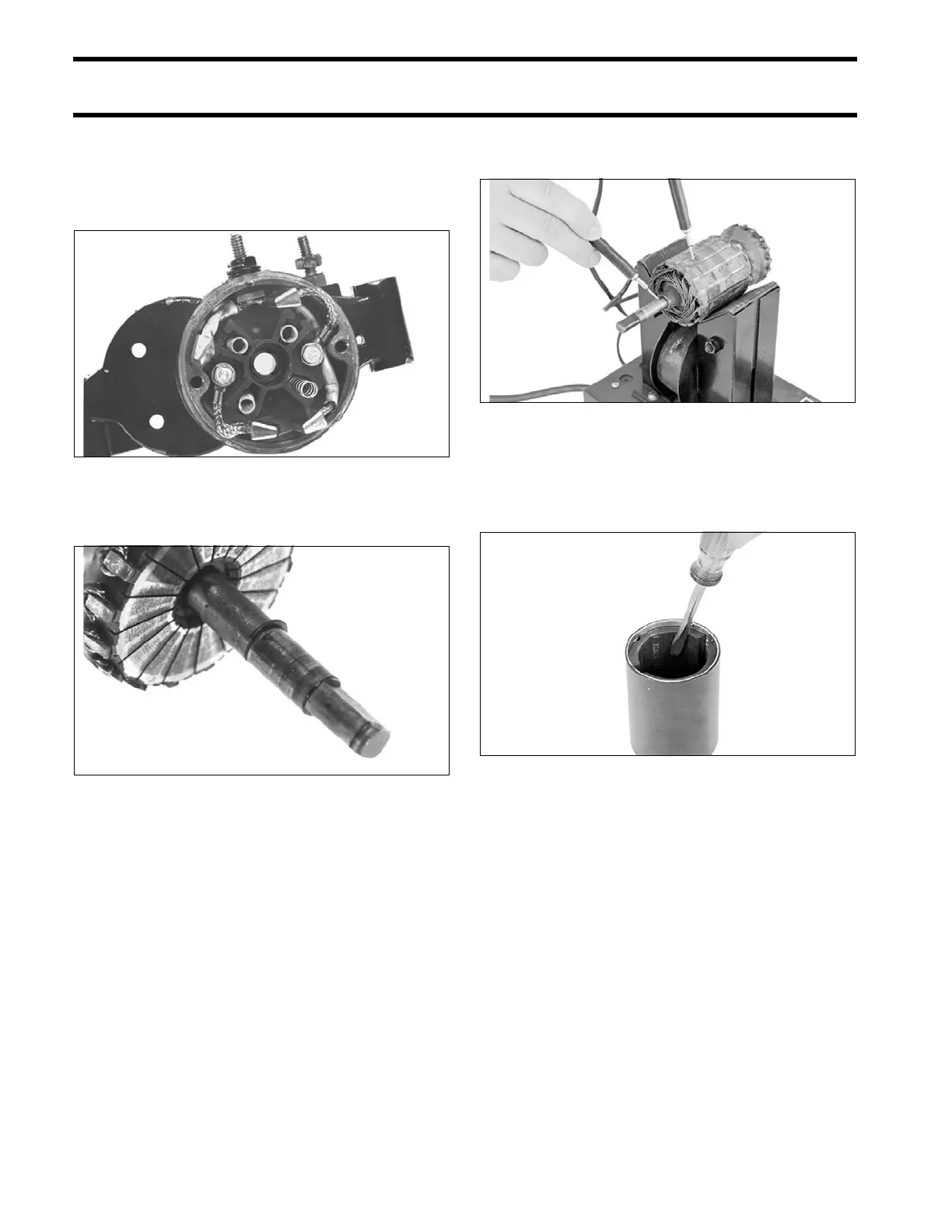

Starter Cleaning and Inspection

Inspect the brushes fo r wear an d dama ge.

Replace brushes if dama ged or worn. Replace

weak brush springs.

Inspect an d rep lace locat ing ring on armature

shaft, if necessary.

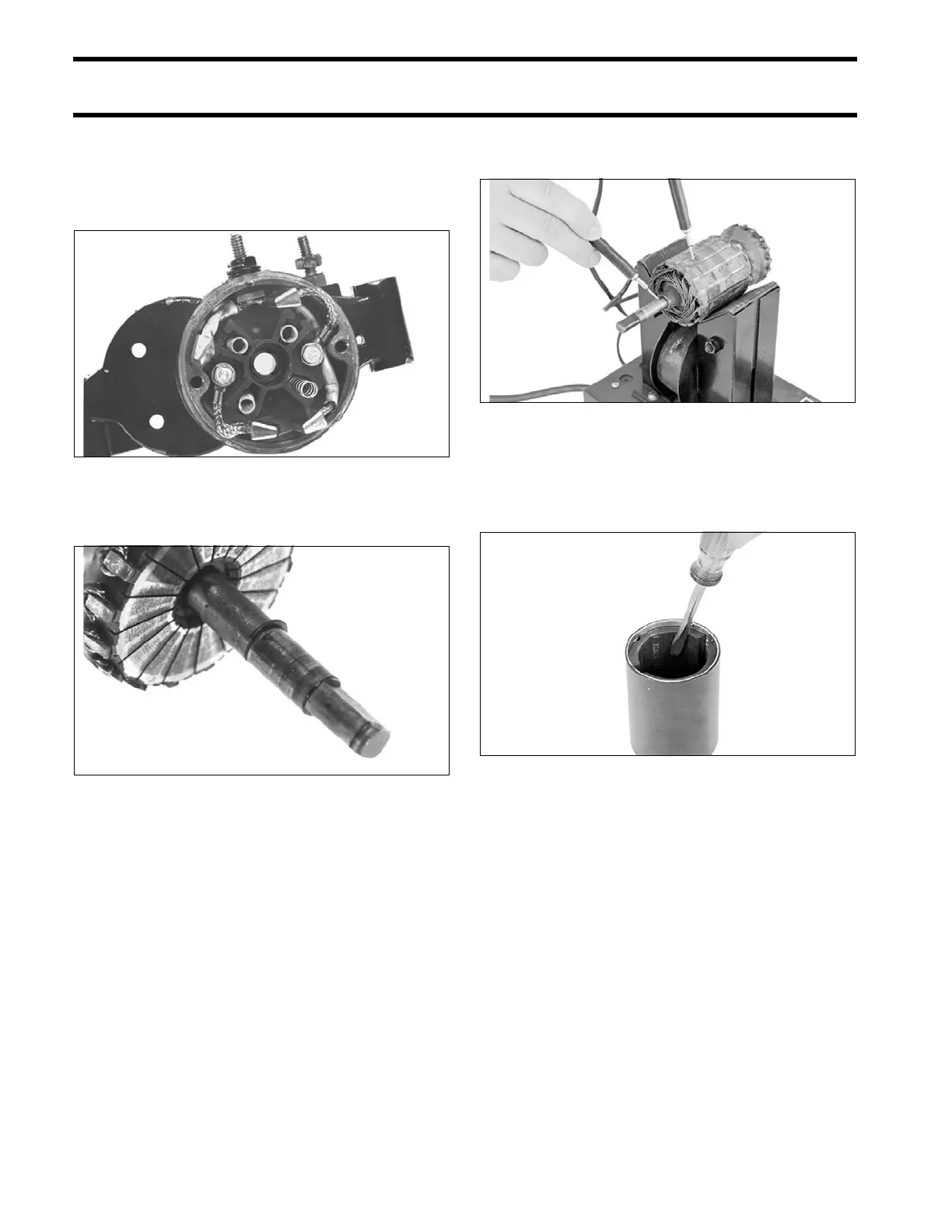

Clean the commut ator with 30 0-grade eme ry

cloth. If commutator surface is u nevenly worn or

pitted, turn it on a lathe. Remove any trace of oil or

metal dust from the commutator.

Check the armature on a growler for shorted turns

using a test light or meter. Inspect armature insu-

lation for ind ications of overheat ing or d amaged

windings. Clean off any carbon deposits or foreign

matter which could con tribute to fa ilure of win d-

ings.

Check permanen t magn ets. Ma ke sure they

strongly attract any steel or iron object held inside

frame. W eak ma gnetism could cause excessive

RPM on No Load Current Draw Test on p. 102.

After disassembling the drive, clean each part with

Cleaning Solvent and inspect for wear and distor-

tion.

If th e pinion does not p roperly eng age th e fly-

wheel, the pinion and screw shaft assembly could

be worn, distort ed, or dirty. Locate the ca use of

binding and cor rect it be fore completing t he

assembly.

Inspect and replace end cap thru st washer if dis-

torted or worn excessively.

Inspect an d re place armature shaf t snap ring if

worn or distorted.

30349

30345

TYPICAL 24058

TYPICAL 24057

Loading...

Loading...