142

FUEL SYSTEM

FUEL SYSTEM TESTS

Results:

Normal pressure

• Perform the Lift Pump Vacuum Test on p. 142.

Make sure no a ir lea ks or restrictions ex ist in

the fuel supply hose or boat fuel system.

Low pressure

• Check pulse hoses and fittings for restrictions.

• Perform the Lift Pump Vacuum Test on p. 142.

Make sure no a ir lea ks or restrictions ex ist in

the fuel supply hose or boat fuel system.

• Check fuel flow through fuel lift pump. Use fu el

primer bulb to force fuel through pump.

No pressure

• Check pulse hoses and fittings restrictions.

• Check fuel flow through fuel lift pump. Use fu el

primer o r primer bulb to force fu el throu gh

pump.

• Momentarily prime or squee ze p rimer bulb to

check gauge operation.

• Check pulse hose and fittings for restrictions.

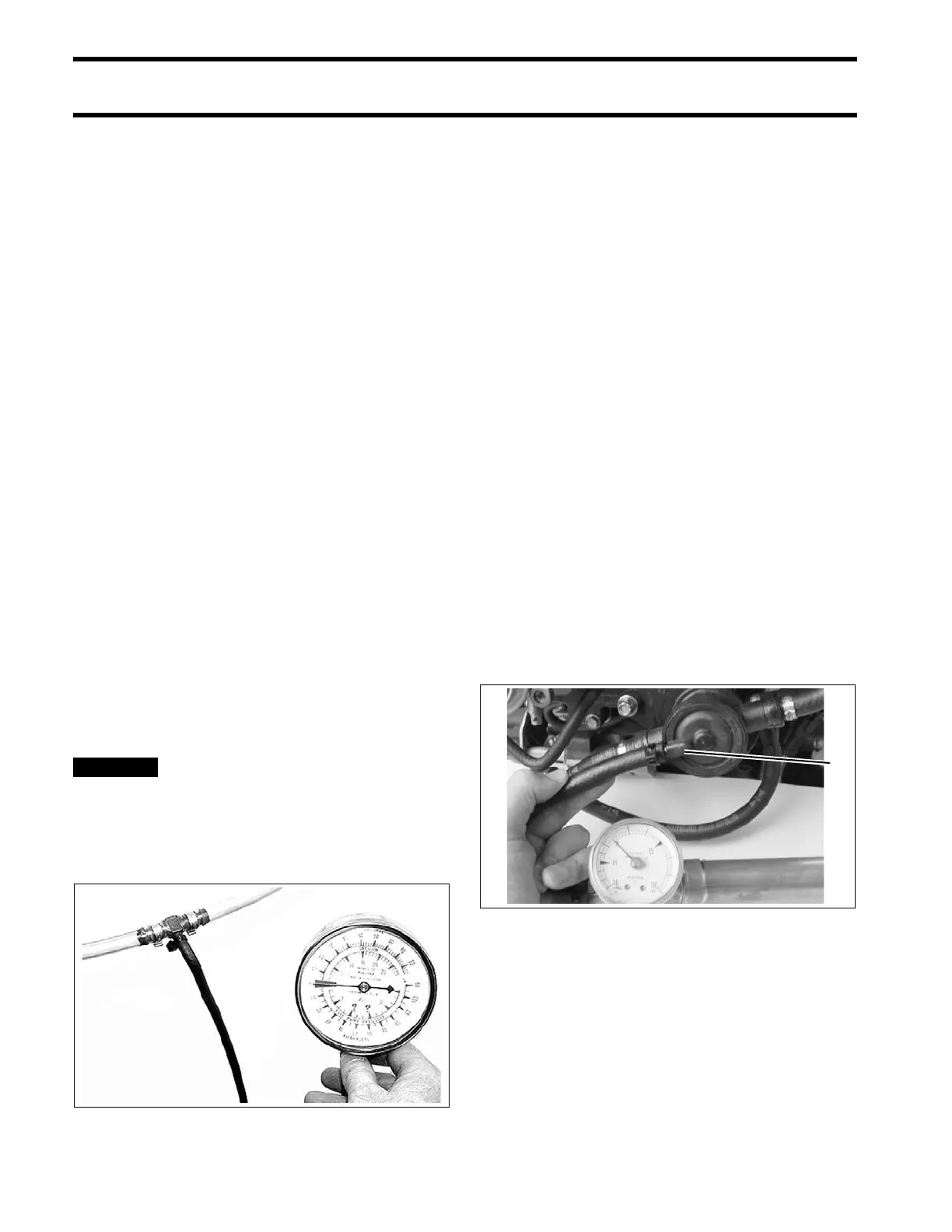

Lift Pump Vacuum Test

Confirm fuel supply to the fuel lift pump.

Temporarily install a vacu um gauge, T-fitting, and

8 in. (20.3 cm) of clear vinyl hose between the fuel

supply hose and fuel lift pump (inlet). Secure con-

nections with tie straps to prevent fuel or air leaks.

Do not use fuel primer bulb, manual

fuel primer, or ele ctric fuel pump primer to

restart o utboard. A posit ive pressu re in the

fuel suppl y could dama ge som e vac uum

gauges.

START outboard and run at FULL THROTTLE for

at least two minutes. Monitor clear vinyl ho se for

the presence of air . Air bubbles ind icate a faulty

hose, connection, o r f uel tank p ick-up. Repair, if

necessary, before proceeding.

There should be no air or vapor bubbles visible in

the clear hose. The maximum inlet fuel va cuum

should not exceed 4 in. Hg. (13.5 kPa) at the inlet

to the fuel lif t pu mp under any o perating cond i-

tions (IDLE to WOT).

A higher vacuum indicate s an excessive restric-

tion in the fuel supply. Repair as needed. Refer to

FUEL SYSTEM REQUIREMENTS on p. 133 for

fuel supply component requirements.

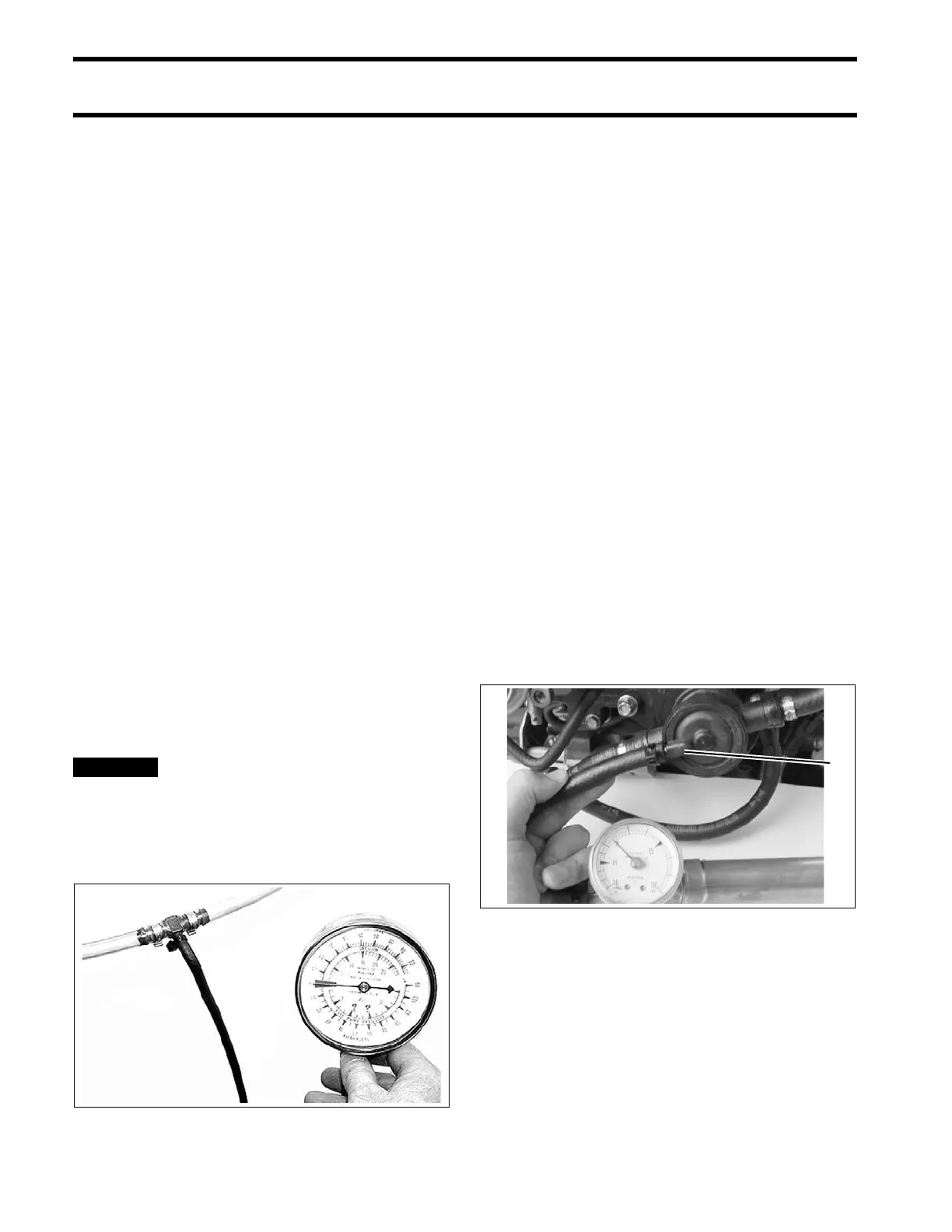

Lift Pump Diaphragm Test

Perform this test only if a damaged pump is sus-

pected. This test does not check the performance

of internal fuel pump check valves.

Remove both pulse hoses from the crankcase fit-

tings.

Apply 15 psi (103 kPa) to each of the pulse hoses

of the pu mp. Replace lif t pu mp if either side of

pump fails to hold pressure.

000243

1. Pulse fitting 000670

Loading...

Loading...