241

POWERHEAD

POWERHEAD INSTALLATION

11

POWERHEAD

INSTALLATION

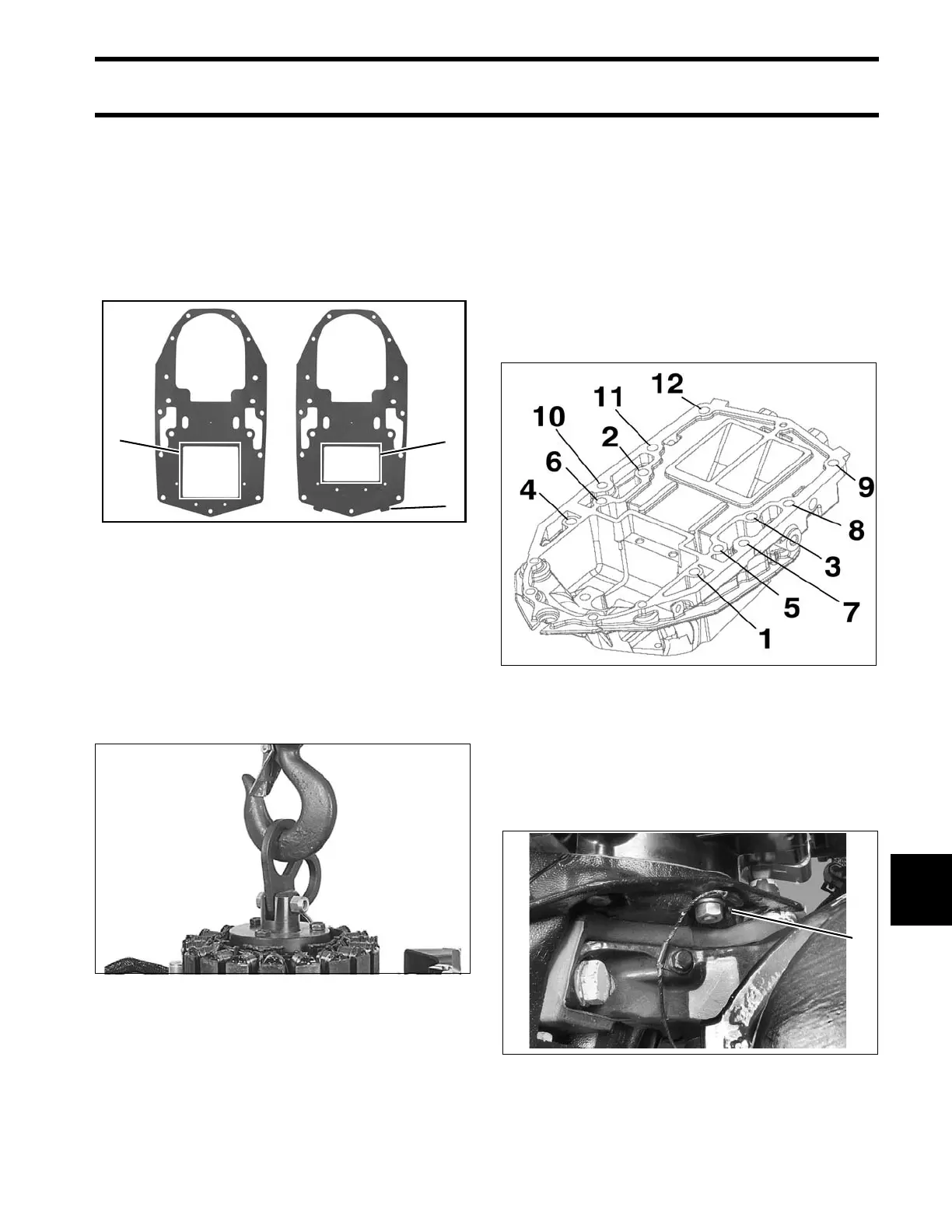

Apply Permatex No. 2 to both sides of a new base

gasket around the exhaust port only. Install gasket

on adapter. To ensure proper sealing, mating sur-

faces must be clean and dry.

Coat the driveshaft splines with Moly Lube. Do not

apply lubricant to end of driveshaft.

Use Lif ting F ixture, P/N 396748, an d hoist to

slowly lower p owerhead ont o exhaust h ousing. If

necessary, rotate flywheel in a clockwise direction

to align crankshaft and driveshaft splines.

Apply Gasket Sealing Compound to the threads of

all powerhead screws.

Loosely install all fasteners before tightening.

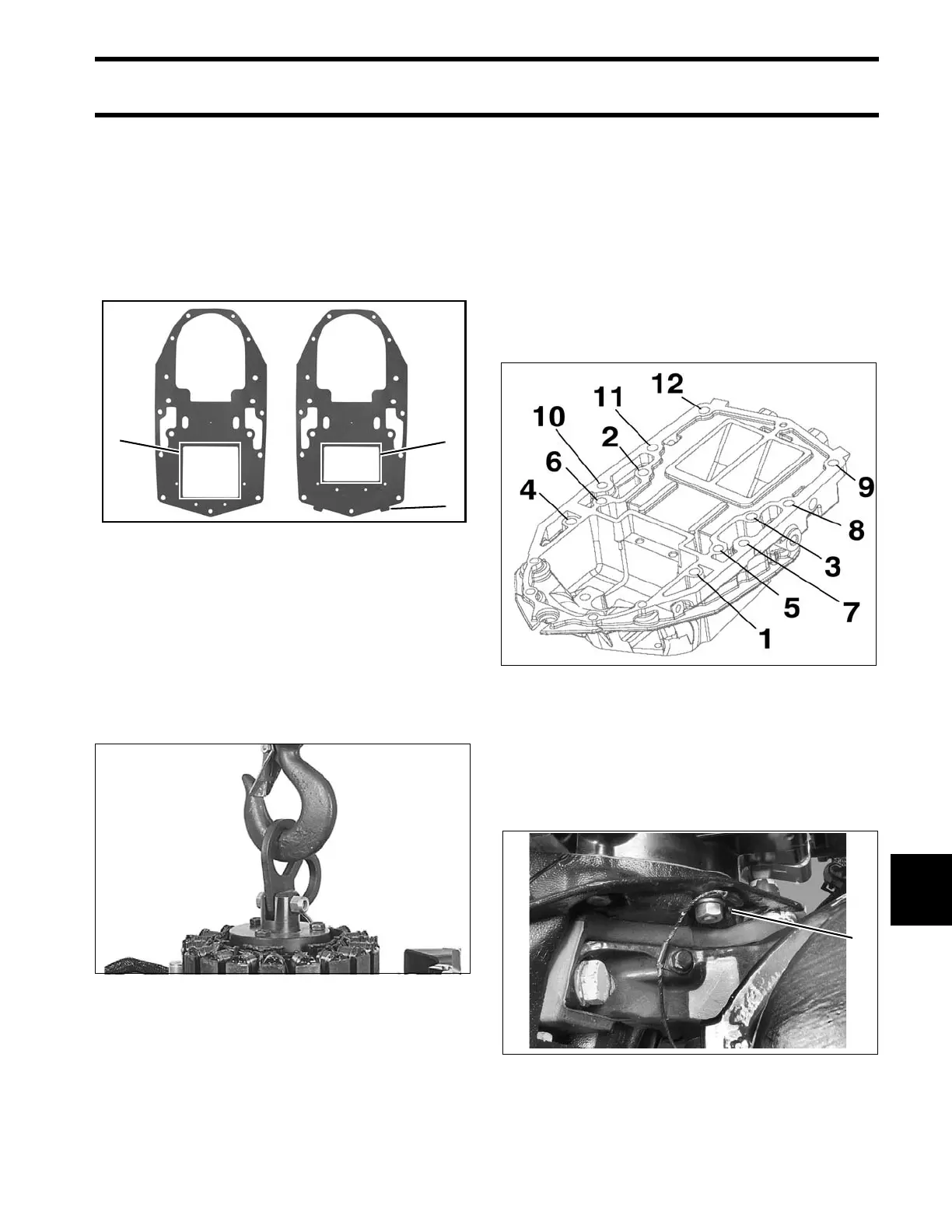

Tighten the 3/8 in. diameter powerhead screws to

a torque of 20 to 22 ft. lbs. (27 to 30 N·m) in the

sequence shown.

Tighten t he 5/1 6 in. diamet er powerh ead screws

to a torque of 144 to 168 in. lbs. (16.5 to 19 N·m)

in the sequence shown.

IMPORTANT: Retighten powerhea d mo unting

screws after outboard has been run at full operat-

ing temperature and allowed to cool.

Install two fro nt and o ne rear po werhead nu ts.

Tighten nuts 144 to 168 in. lbs. (16.5 to 19 N·m).

Crankcase to Adaptor Gaskets

1. Exhaust port area – 3.3 L models

2. Exhaust port area – 3.4 L models

3. Identification tab (3.4 L models only)

008324

48758

004261

1. Front powerhead nut (2) 004262

Loading...

Loading...