239

POWERHEAD

POWERHEAD ASSEMBLY

11

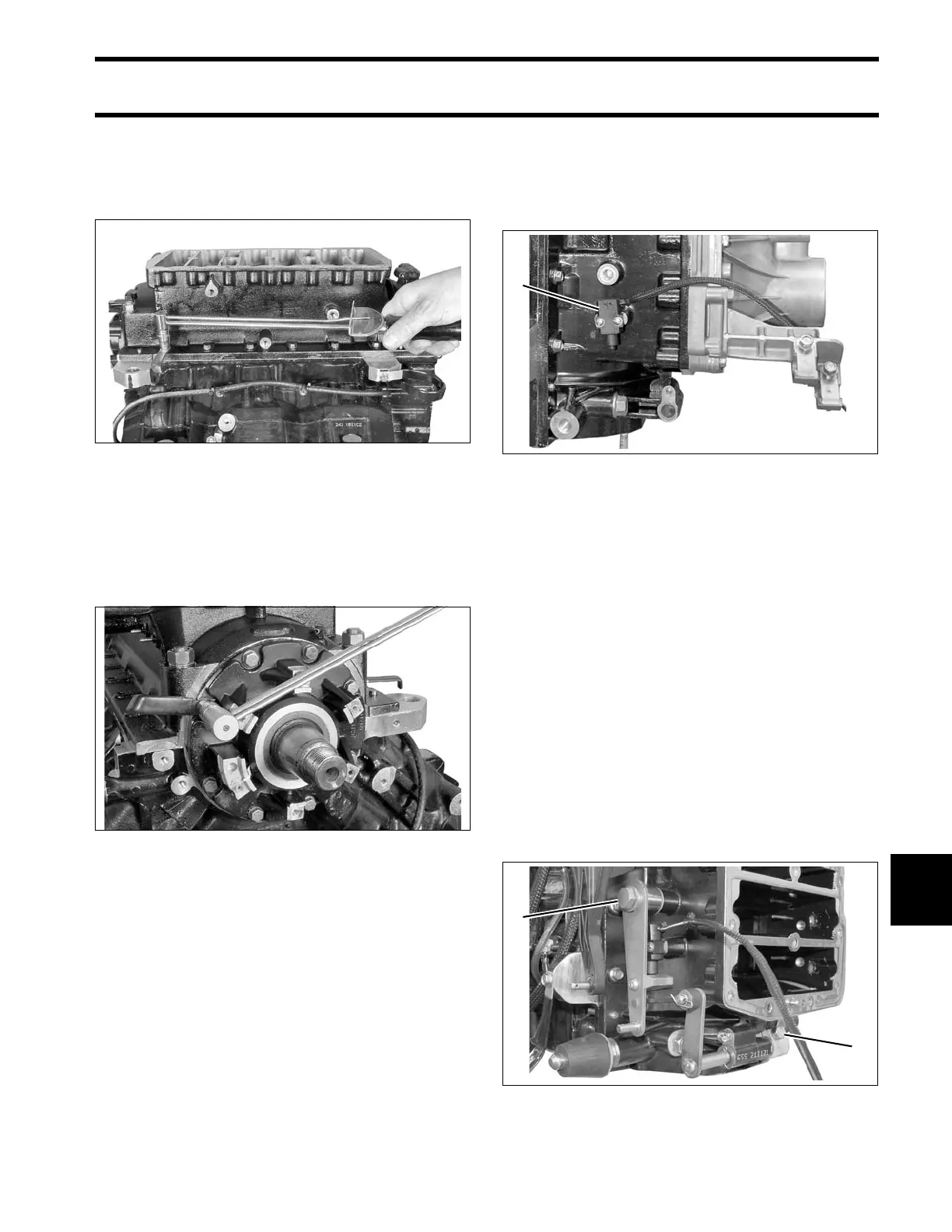

Apply Permatex No. 2 to crankcase flange screws

where thre aded hole is op en to crankcase .Install

screws and tighten to a torque of 84 to 108 in. lbs.

(9.5 to 12 N·m).

Test that the crankshaft spins freely without bind-

ing.

Apply Nut Lock to the upper and lower crankcase

head screws. Install and tight en screws t o a

torque of 96 to 120 in. lbs. (11 to 13.5 N·m).

IMPORTANT: After powerhead ha s be en

assembled, allow at least two hours for Gel-Seal II

to cure before running outboard.

Shift Linkage Installation

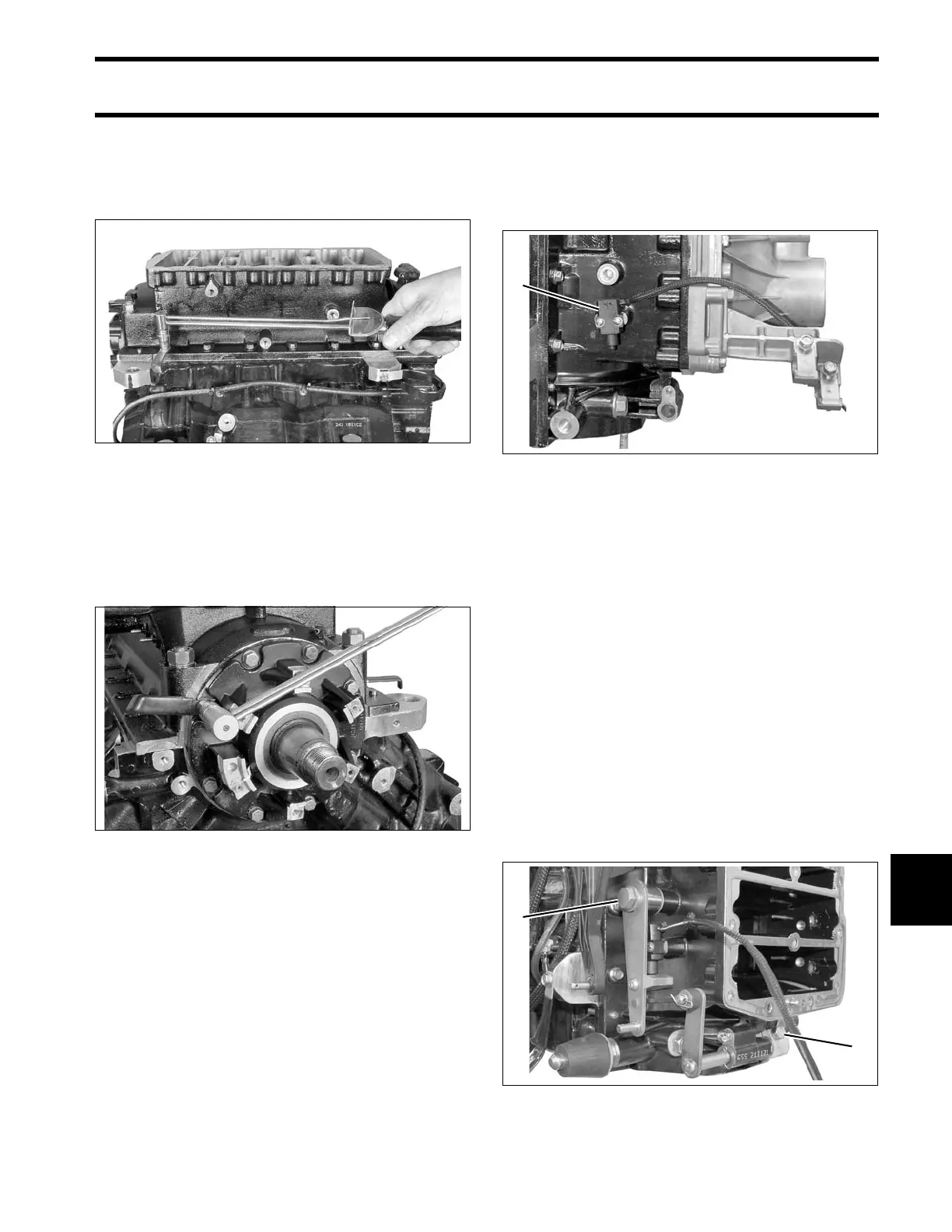

Install Neut ral/Shift In terrupt switch. Apply Nut

Lock to screw threads and tighten to a torque of 7

to 10 in. lbs. (0.8 to 1.1 N·m).

If removed , install cam on shif t arm. Apply Ultra

Lock to screw threa ds and tighten to a torqu e of

60 to 84 in. lbs. (7 to 9.5 N·m).

Lubricate sh ift linkage bosses a t the base of th e

crankcase with Triple-Guard grease. Inse rt bush-

ings into bosses.

Apply Triple-Guard grease to the shaft of the shift

lever assembly. Guide shaft through bushings in

crankcase.

Install shif t rod le ver an d tight en ret aining screw

60 to 84 in. lbs. (7 to 9.5 N·m).

Apply Triple-Guard grease to shoulder of shift arm

screw and Nut Lock to threads. Install arm, screw,

and washer a nd tighten screw to a torque of 120

to 144 in. lbs. (13.5 to 16.5 N·m).

004138

004142

1. Neutral/Shift Interrupt switch 008451

1. Shoulder screw

2. Shift rod lever retaining screw

008455

Loading...

Loading...