37

.ROUTINE SERVICE

LUBRICATION

2

• Inner casings of both the thro ttle and shift

cables.

Shift the re mote control to the NEUTRAL/IDLE

position.

Install control cables.

Check proper throttle and shift function.

Propeller Shaft

Debris from the water can become lodged around

propeller shaft. Frequent inspection can minimize

potential gearcase damage.

Remove pro peller. Re fer to Propeller Hardware

Installation on p. 287.

Inspect bushing a nd blad e surfa ces. Re place

damaged or worn propellers.

Clean p ropeller shaft. Inspect pro peller shaf t

seals. Replace damaged or worn seals.

Apply Triple-Guard grease to entire length of pro-

peller shaft prior to installing propeller.

Reinstall propeller hardware and propeller.

Gearcase Lubricant

Draining

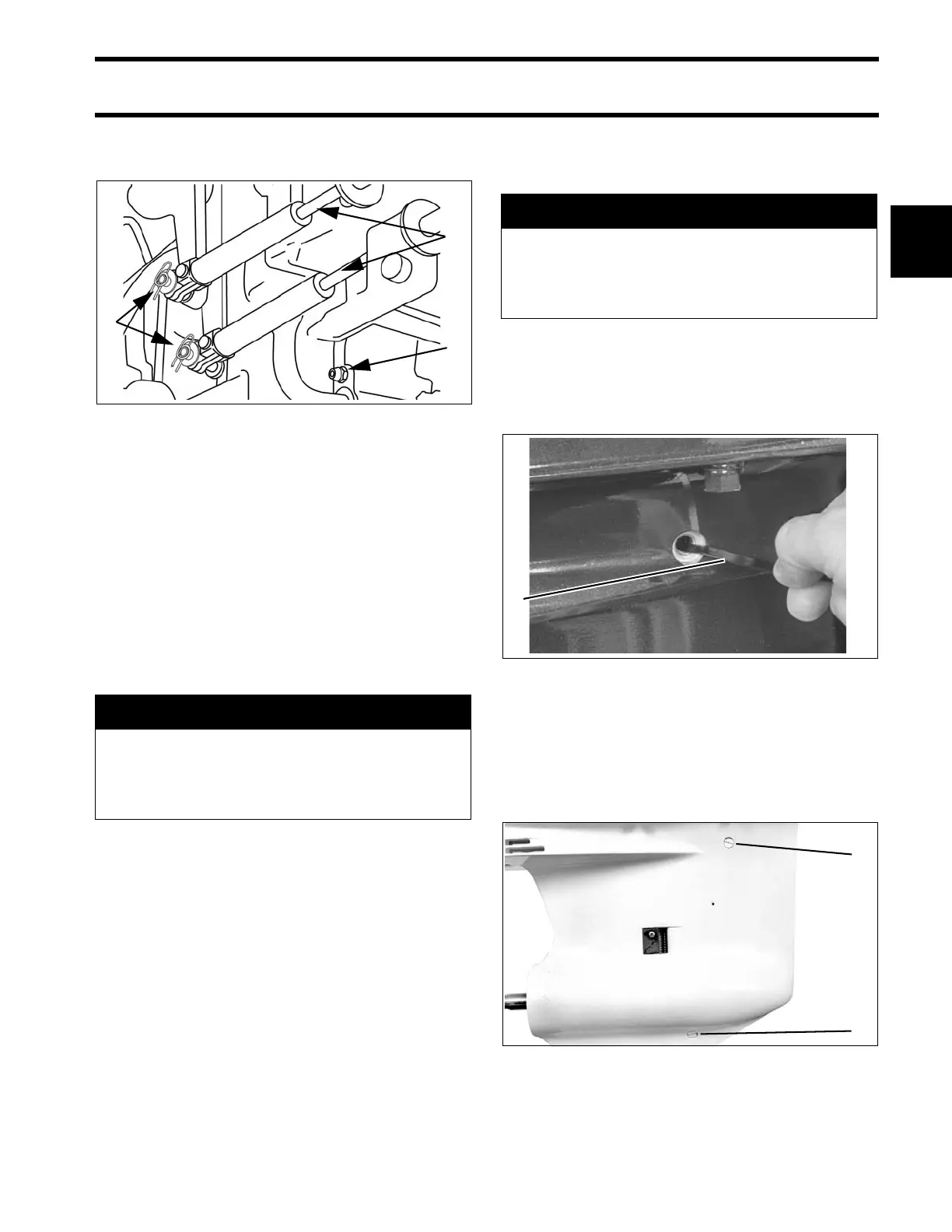

IMPORTANT: Always check the fill le vel of the

gearcase lub ricant at the u pper plug befo re

removing the lower, drain/fill plug. A tie st rap can

be used to check lubricant level.

If lubricant level is low, refer to GEARCASE LEAK

TEST on p. 288.

Remove the lubricant level plug, then the lubricant

drain/fill plug, an d dr ain the lube from th e

gearcase into a container.

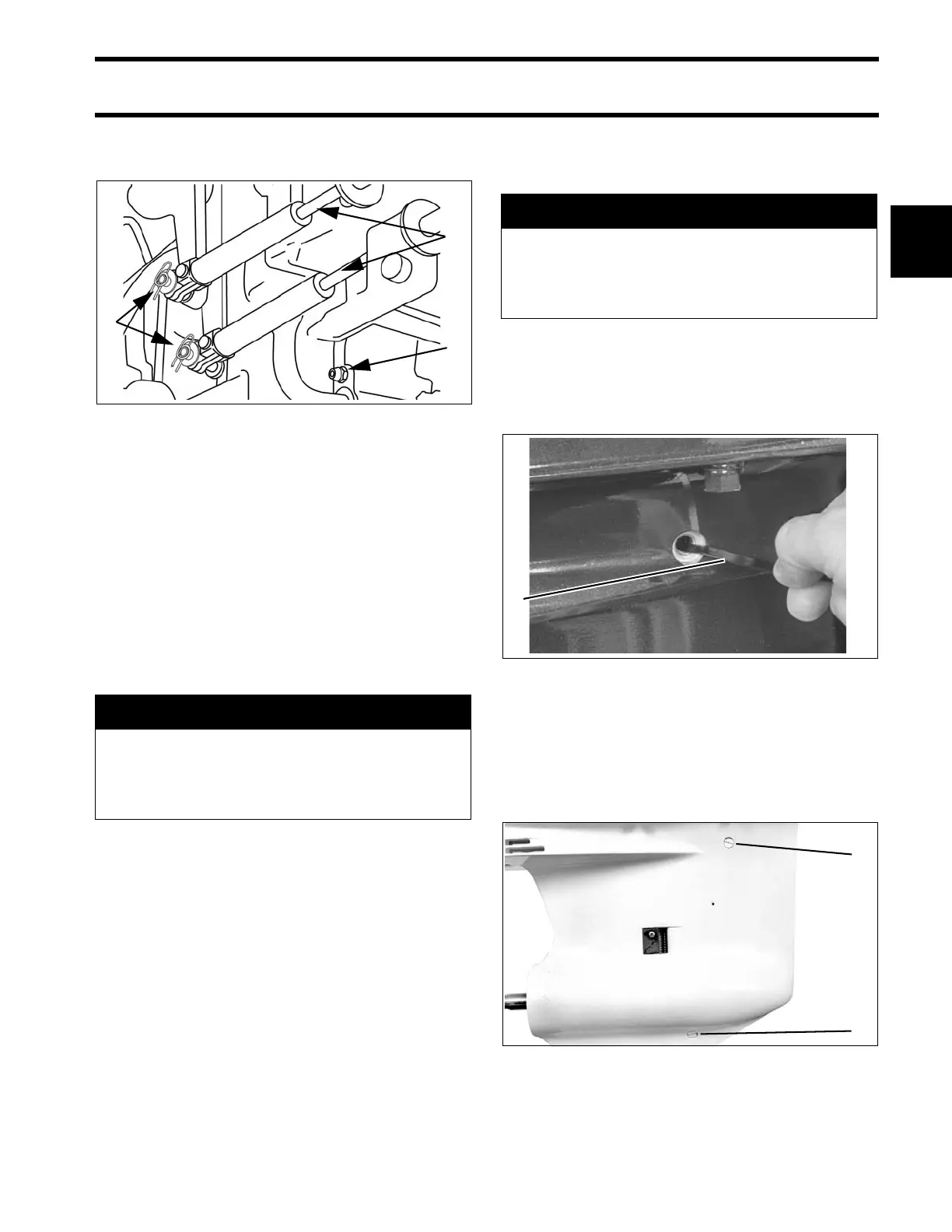

1. Attachment pins, throttle and shift cables

2. Shift shaft grease fitting

3. Inner casings, throttle and shift cables

DRC6500R

A WARNING

When servicing the propeller, always shift

the outboard to NEUTRAL, turn the key

switch OFF, and d isconnect the batte ry

cables at the battery.

A WARNING

Gearcase lubricant may be under pressure

and/or hot. If plug is remove d from a

recently operated outboa rd, take precau-

tions to avoid injury.

1. Tie strap 000072

1. Lubricant level plug

2. Lubricant drain/fill plug

39514

Loading...

Loading...