290

GEARCASE

GEARCASE REMOVAL AND INSTALLATION

Gearcase Installation

Before installing gearcase, shift rod

adjustment MUST be checked. Refer t o SHIFT

ROD ADJUSTMENT on p. 295.

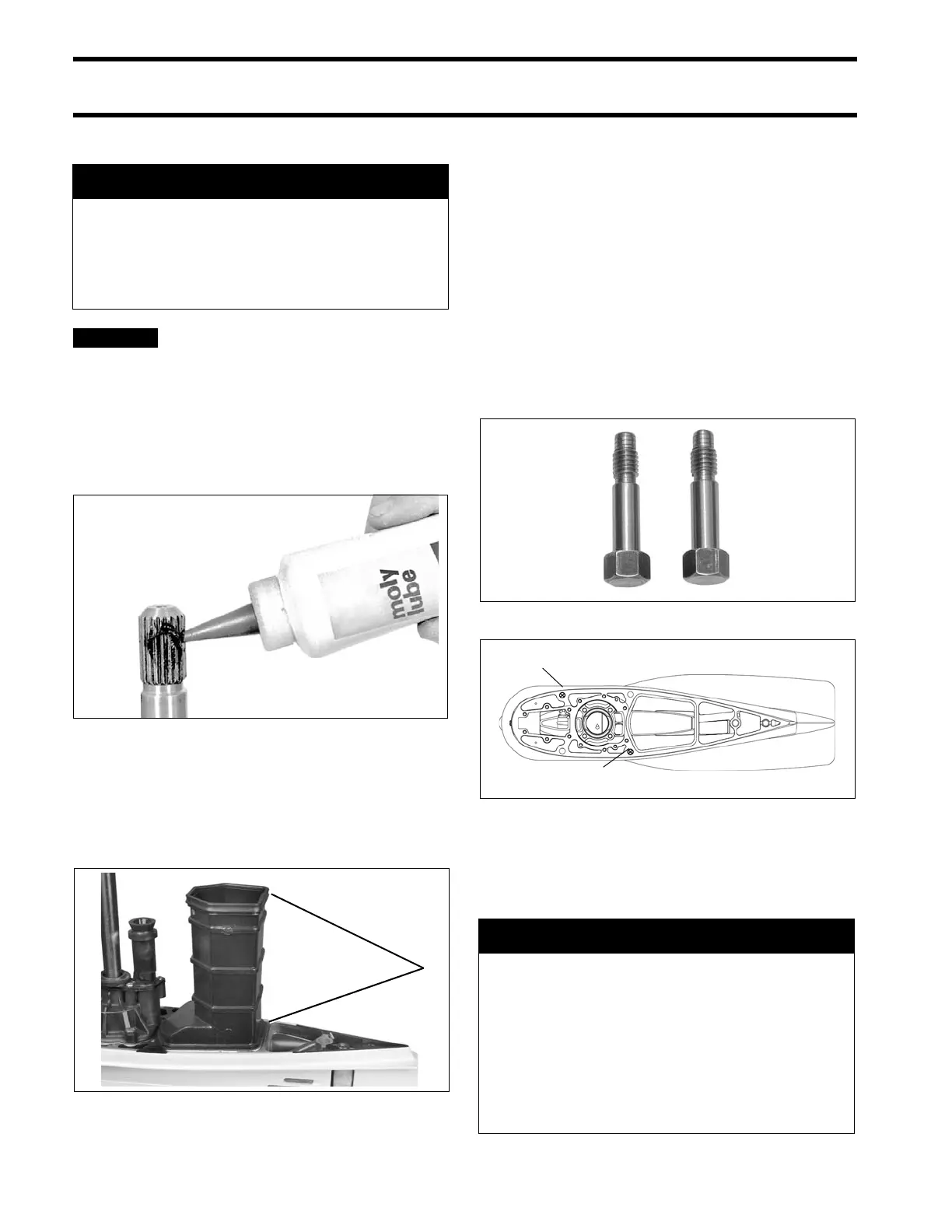

Coat th e drivesh aft splines with Moly Lube. DO

NOT co at top su rface of th e driveshaf t be cause

lubricant may prevent seat ing of the driveshaf t in

the crankshaft.

Apply Adhesive 847 to the lo wer exhaust housing

seals’ inner surfaces. Place two new seals on the

housing. Apply Triple-Guard grease to the seals’

outer surfaces and pla ce the housing on the

gearcase.

Slide the gearcase into place, making sure:

• Driveshaft engages the crankshaft.

• Water tube enters the water pump.

• Lower inner exhaust housing installs correctly.

• Shift ro d does not turn an d is positio ned pro p-

erly in the shift rod lever below the crankcase.

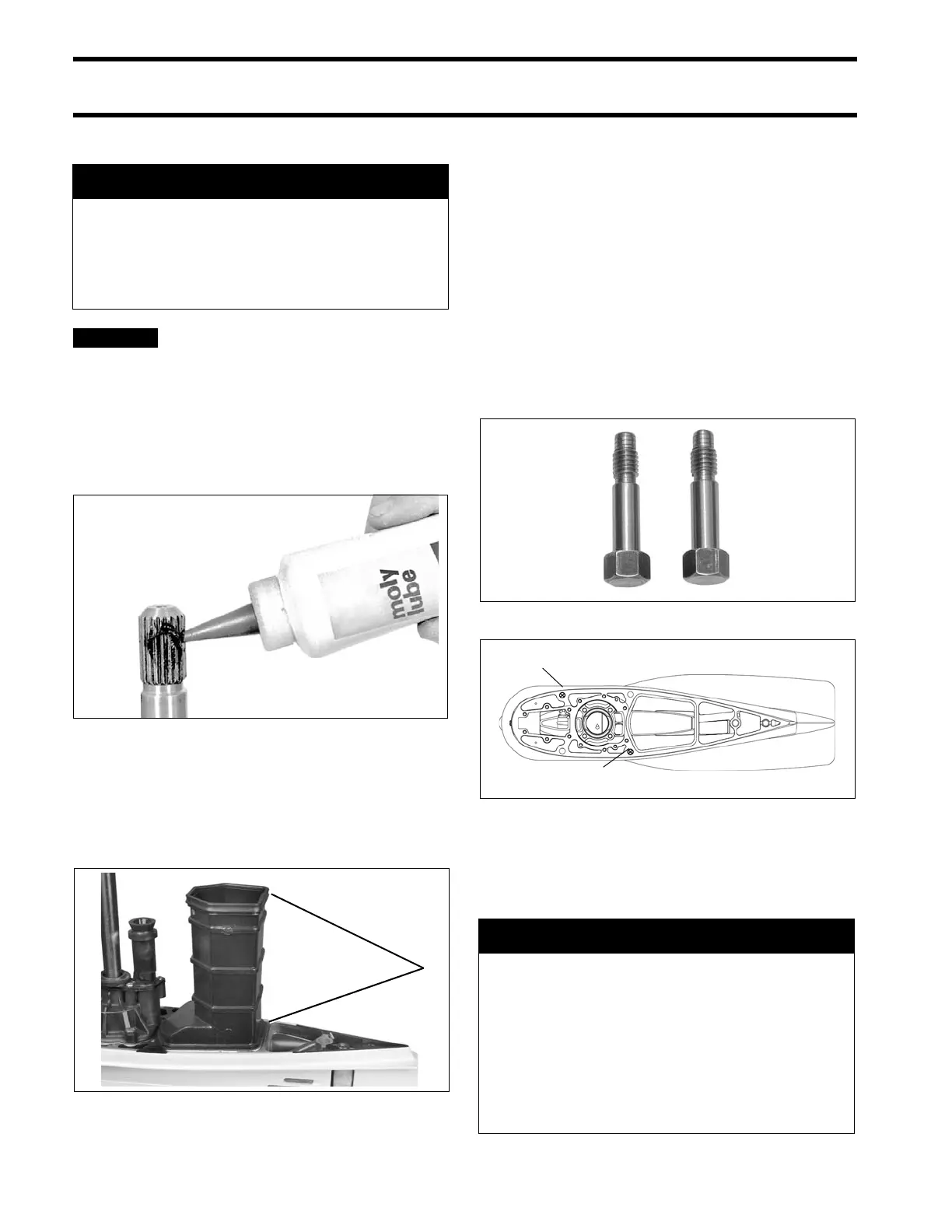

Some outboa rd mode ls include hollow alignme nt

pins between the exhaust housing and gearcase.

If o utboard is not equipped with alignment pins,

use Gea rcase Alig nment Kit, P/N 5 007231, to

accurately align gearcase h ousing to exhaust

housing. Position alignment bolts (2) as indicated.

IMPORTANT: Replace alignment b olts with

mounting scre ws after all other gearcase mou nt-

ing screws are installed.

A WARNING

During service, the outboard may drop

unexpectedly. A void perso nal inju ry;

always support the outboard’s weight with

a suitable hoist or the tilt support bracket

during service.

30385

1. Lower exhaust seals 001985

Alignment Bolt(s) 005401

1. Position of alignment bolts (2) 005402

A WARNING

Failure to properly tighte n gearcase

screws with a torque wrench could lead to

gearcase damage or loss, resulting in loss

of control and possible personal injury.

Screw torque should be checke d regu-

larly, e specially in high-speed a pplica-

tions, or any t ime p ropeller d amage has

occurred.

Loading...

Loading...