311

GEARCASE – STANDARD ROTATION

DRIVESHAFT SHIMMING

13

Select collar, P/N 341440, and th e co rrect shim

gauge bar:

• “M2”: Shim gauge bar, P/N 349957

• “L2”: Shim gauge bar, P/N 328367

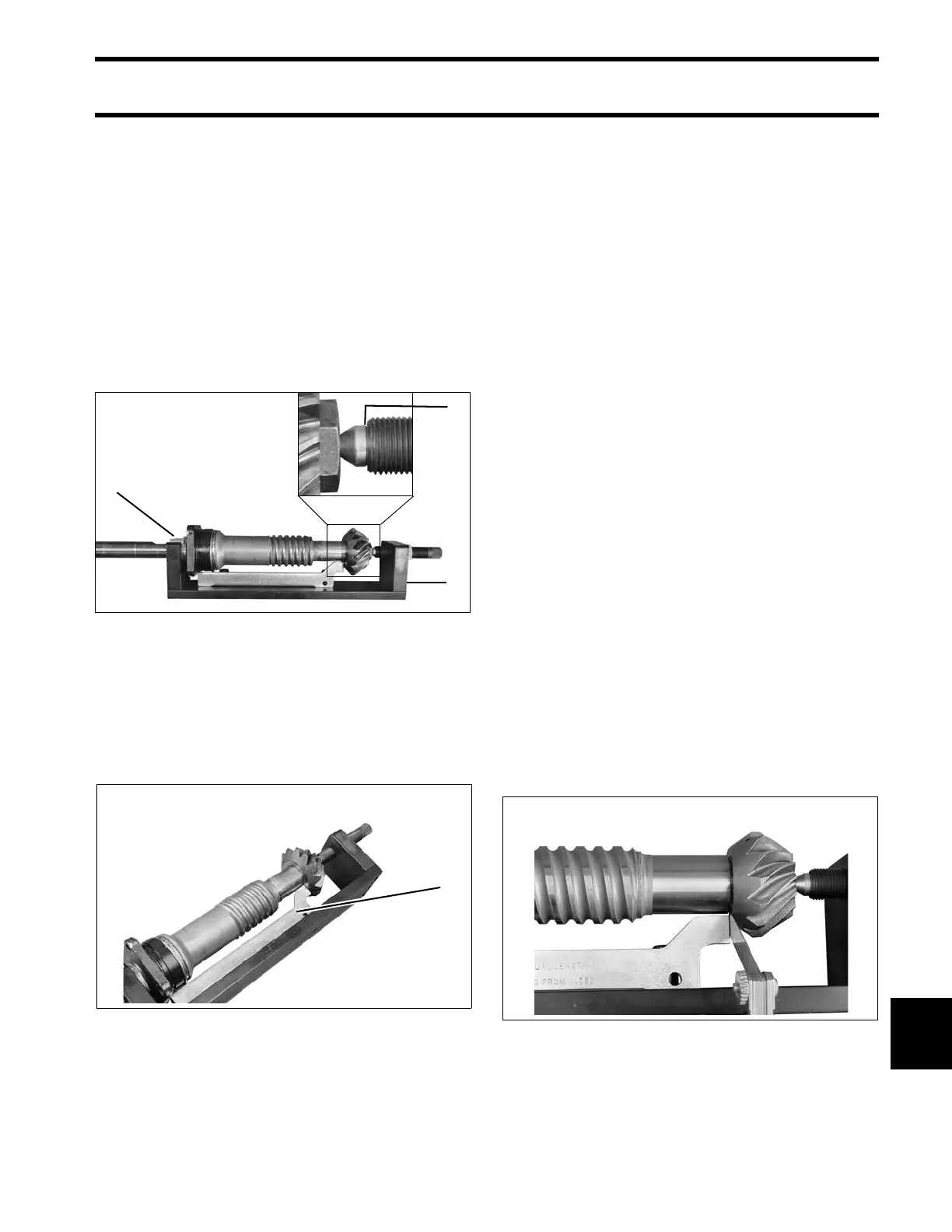

Slide the collar onto the driveshaft with large e nd

in contact with the bearing housing.

Insert the assembled driveshaft into the tool base

and t ighten p reload screw against the driveshaf t

until groove on the sp ring-loaded plunger is flush

with end of thread s. Tighten locking ring on pre-

load screw.

Rotate the driveshaft se veral revolutio ns to seat

bearings.

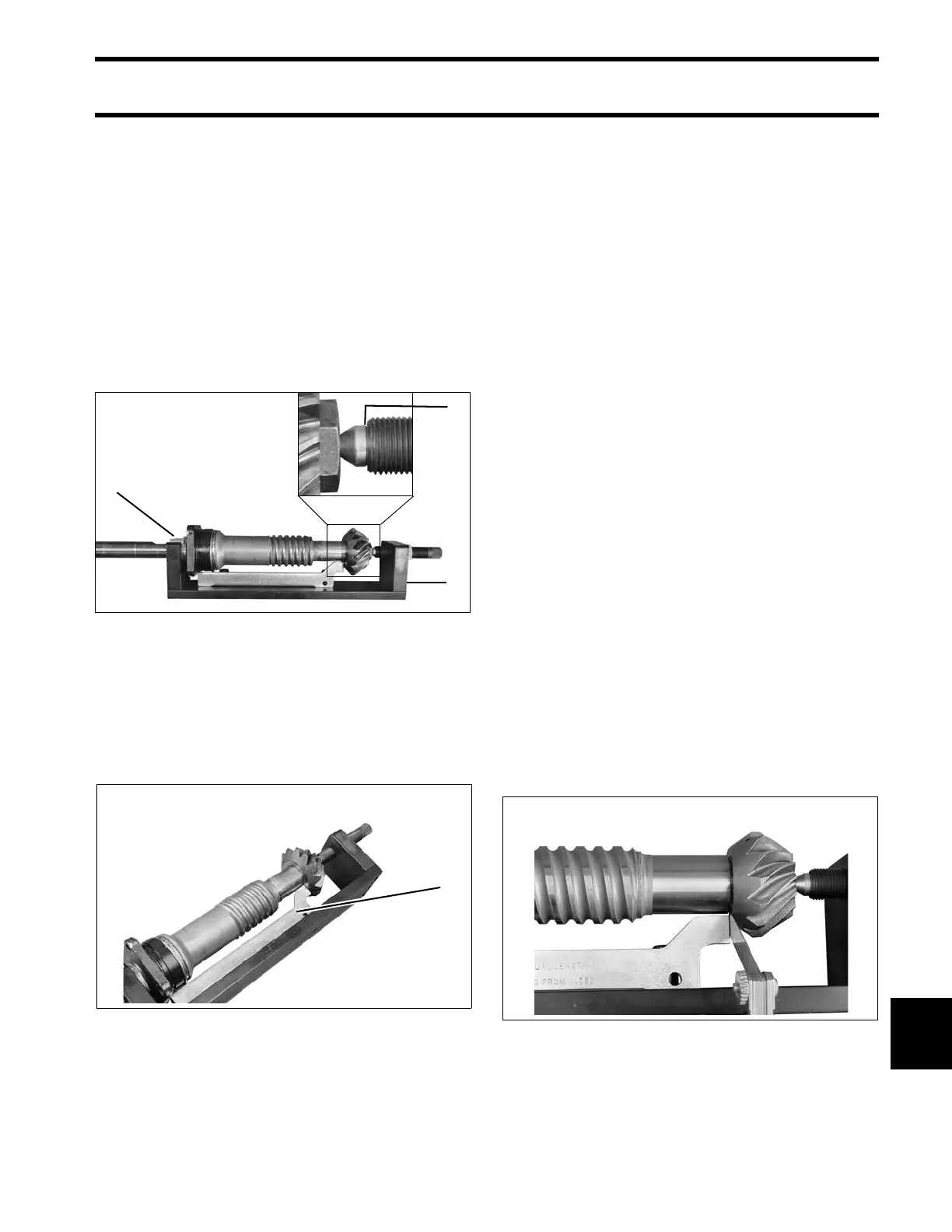

Lay th e tool base on it s side. Position the shim

gauge bar against guide pins of the tool base.

Check squareness of the be aring housing mount-

ing surface by holding the shim gauge bar against

the pinion while rot ating just th e be aring ho us-

ing. Use a fe eler g auge to me asure cle arance

between the g auge b ar and th e bearing ho using

between each p air of screw hole s. Re place the

bearing housing a nd rep eat check if var iance is

greater than 0.004 in. (0.101 mm).

Check squareness of t he pinion to th e driveshaft.

Hold the shim ga uge b ar aga inst the bearing

housing (between the screw holes) wh ile rotating

just the drive shaft and pinio n assembly. Mea-

sure clear ance betwee n th e ga uge bar a nd th e

pinion a t several location s. If varian ce is grea ter

than 0.002 in. (0.0 50 mm) replace the pinion or

driveshaft, as necessary, and repeat check.

Subtract th e average clearance measureme nt

from 0.020 in . (0.508 mm) to determine the cor-

rect shim thickn ess requ ired. Select th e fewest

number of shims to achieve the correct thickness.

Remove the driveshaft from the tool and add the

required shims be tween the b earing housing an d

the thrust washer.

IMPORTANT: Use extreme care when removing

bearing housing to avoid damaging the seals. Use

Driveshaft Seal Protector, P/N 318674.

Check cleara nce a gain. The measureme nt

between the gaug e bar and pinion should be

0.020 in. (0.508 mm).

Remove th e nut and pinion from the driveshaf t.

Discard the nut.

1. Collar

2. Tool base

3. Groove

006912

006913

1. Shim gauge bar 006914

005417

Loading...

Loading...