117

ELECTRICAL AND IGNITION

TIMING ADJUSTMENTS

6

TIMING ADJUSTMENTS

Timing Pointer

The timing pointer must be adjusted to indicate

top dead center (TDC) of the number 1 piston.

This reference to the position of the number 1 pis-

ton is used to synchronize the electronic timing

controlled by the EMM with the mechanical posi-

tion of the number 1 piston.

Always check timing pointer adjustment before

using the Evinrude Diagnostics software Timing

Verification procedure.

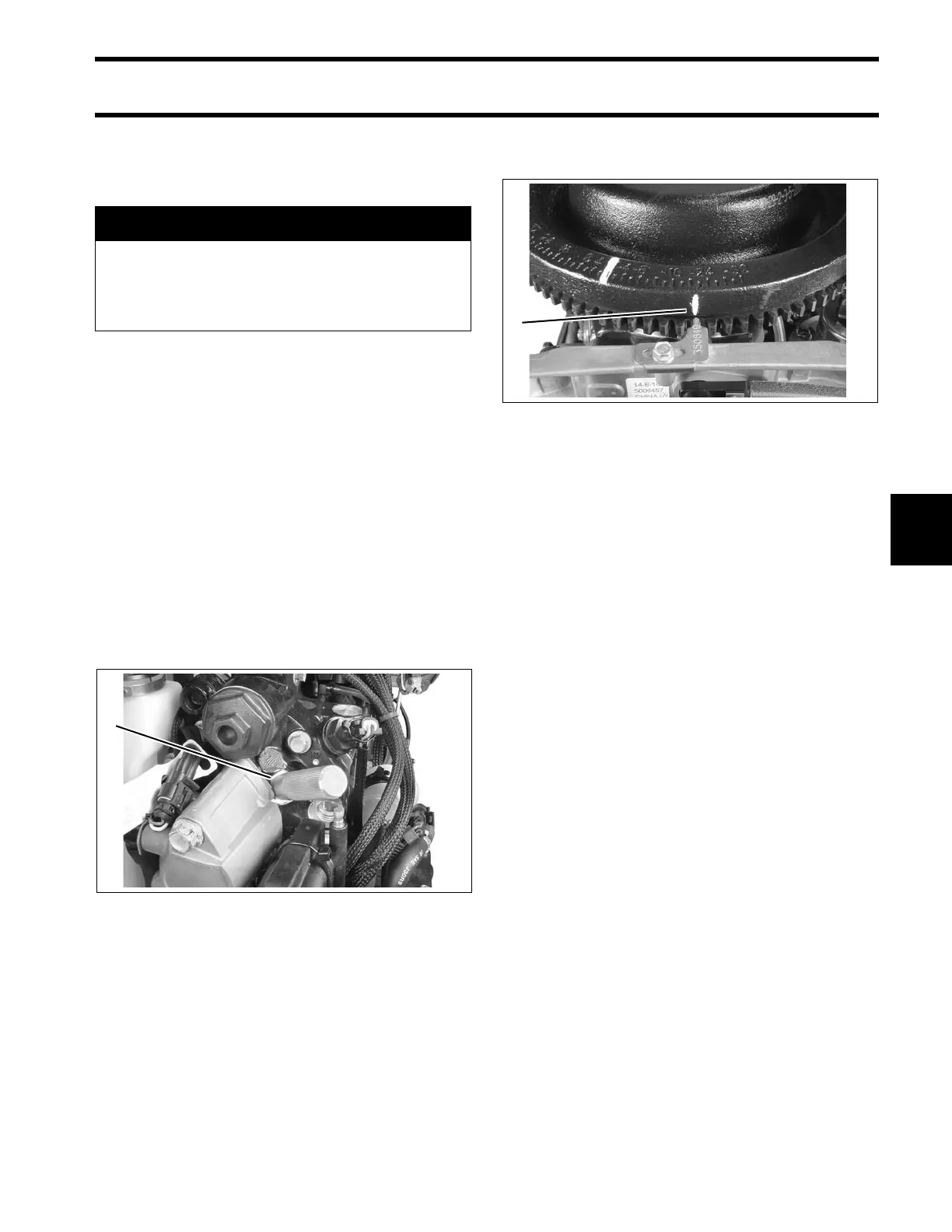

Remove spark plugs. Rotate the flywheel clock-

wise to approximately 30° ATDC.

Install Piston Stop Tool, P/N 342679, into the

spark plug hole of the number 1 cylinder.

Rotate flywheel counterclockwise until the num-

ber 1 piston contacts the tool. Keep pressure on

the flywheel to position the piston firmly against

the tool. Mark the flywheel directly across from the

pointer. Label this mark “A.”

Rotate the flywheel clockwise until the piston

contacts the tool. Mark the flywheel directly across

from the pointer. Label this mark “B.” Rotate fly-

wheel counterclockwise slightly to release tool

then remove it from spark plug hole.

Use a flexible measuring device, such as a piece

of string, to find the exact center between marks

“A” and “B.” Measure along the edge of the fly-

wheel. Mark and label the center point “C.”

If mark “C” and the cast-in TDC boss on flywheel

are in alignment, the timing pointer is in the cor-

rect location.

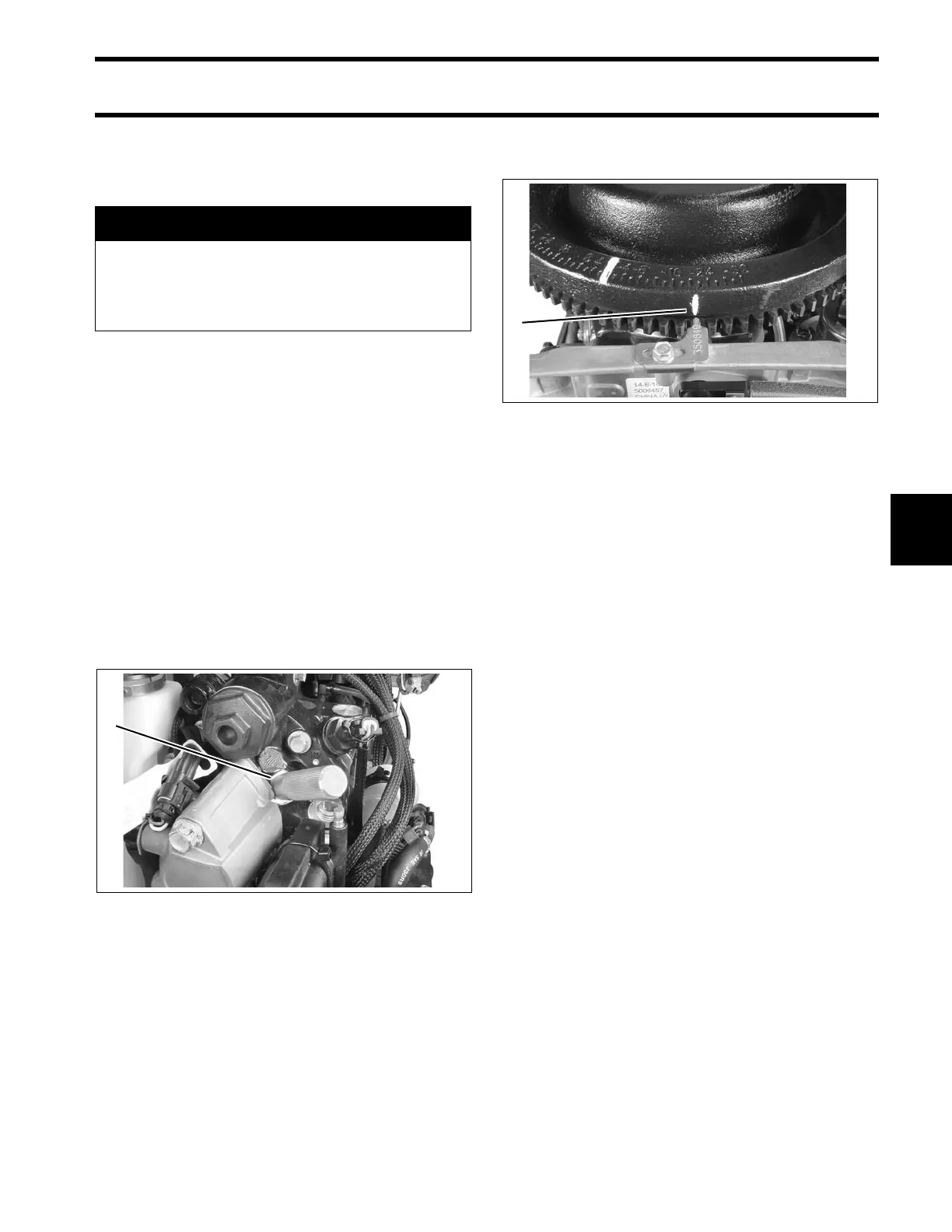

If the pointer alignment is NOT correct, rotate the

flywheel clockwise to align the mark “C” with the

pointer. Hold the flywheel in this position. Loosen

the pointer retaining screw and adjust the pointer

A WARNING

To prevent accidental starting while servic-

ing, disconnect the battery cables at the

battery. Twist and remove all spark plug

leads.

1. Piston stop tool 006493

1. Timing pointer 006552

Loading...

Loading...