216

POWERHEAD

POWERHEAD ASSEMBLY

Start in the center and work outward in a spiral

pattern.

Apply Nut Lock to crankcase flange screws. Install

screws and tighten to a torque of 60 to 84 in. lbs.

(7 to 9.5 N·m).

Test that the crankshaft spins freely without bind-

ing.

IMPORTANT: After powerhead has been

assembled, allow at least two hours for Gel-Seal II

to cure before running outboard.

Apply Gasket Sealing Compound to both sides of

a new water cover gasket. Place gasket and cover

on cylinder block.

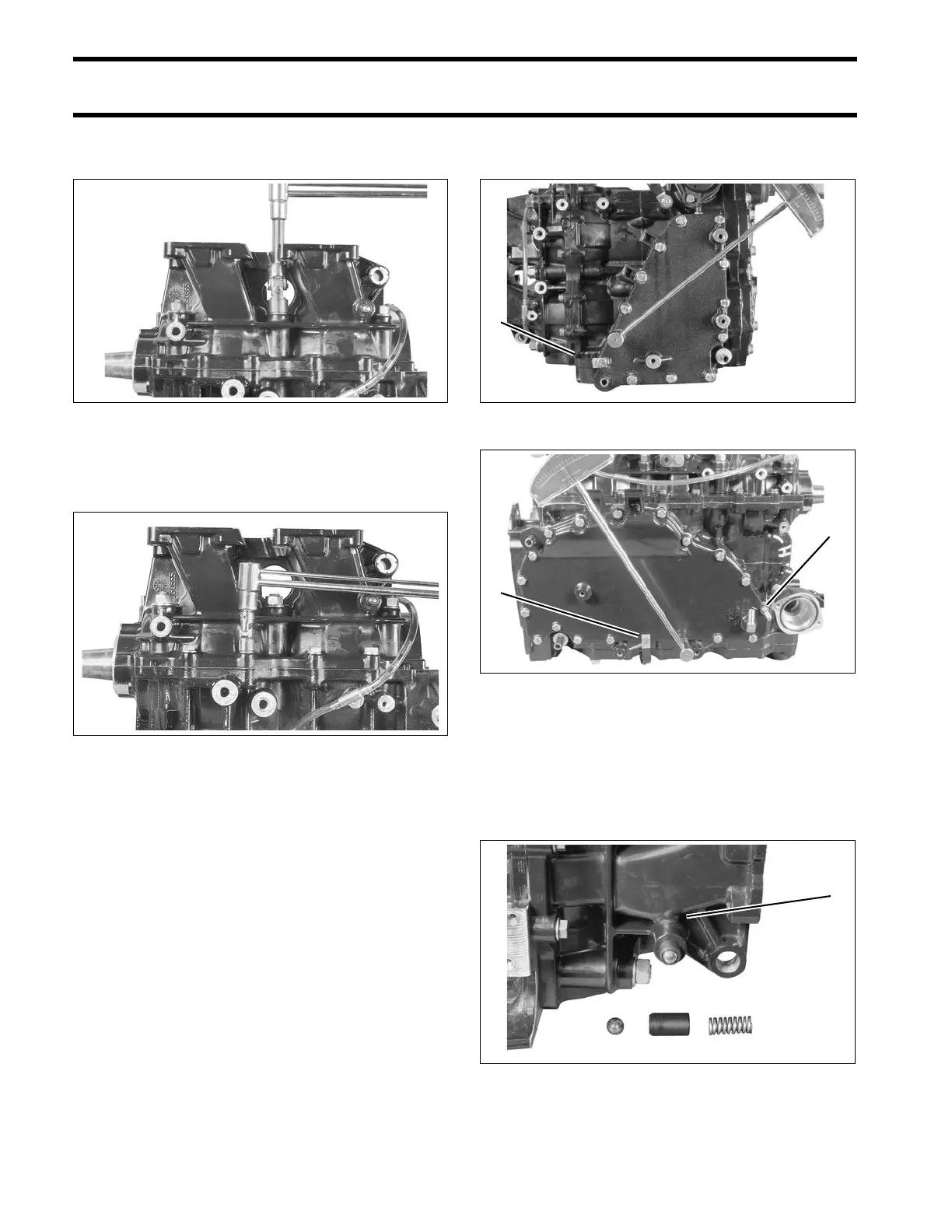

Apply Nut Lock to cover screws. Position J-

clamps as shown. Tighten all screws to a torque of

60 to 84 in. lbs. (7 to 9.5 N·m).

Note: 3-Cylinder models include a double-ended

stud and use a lock washer under the J-clamp.

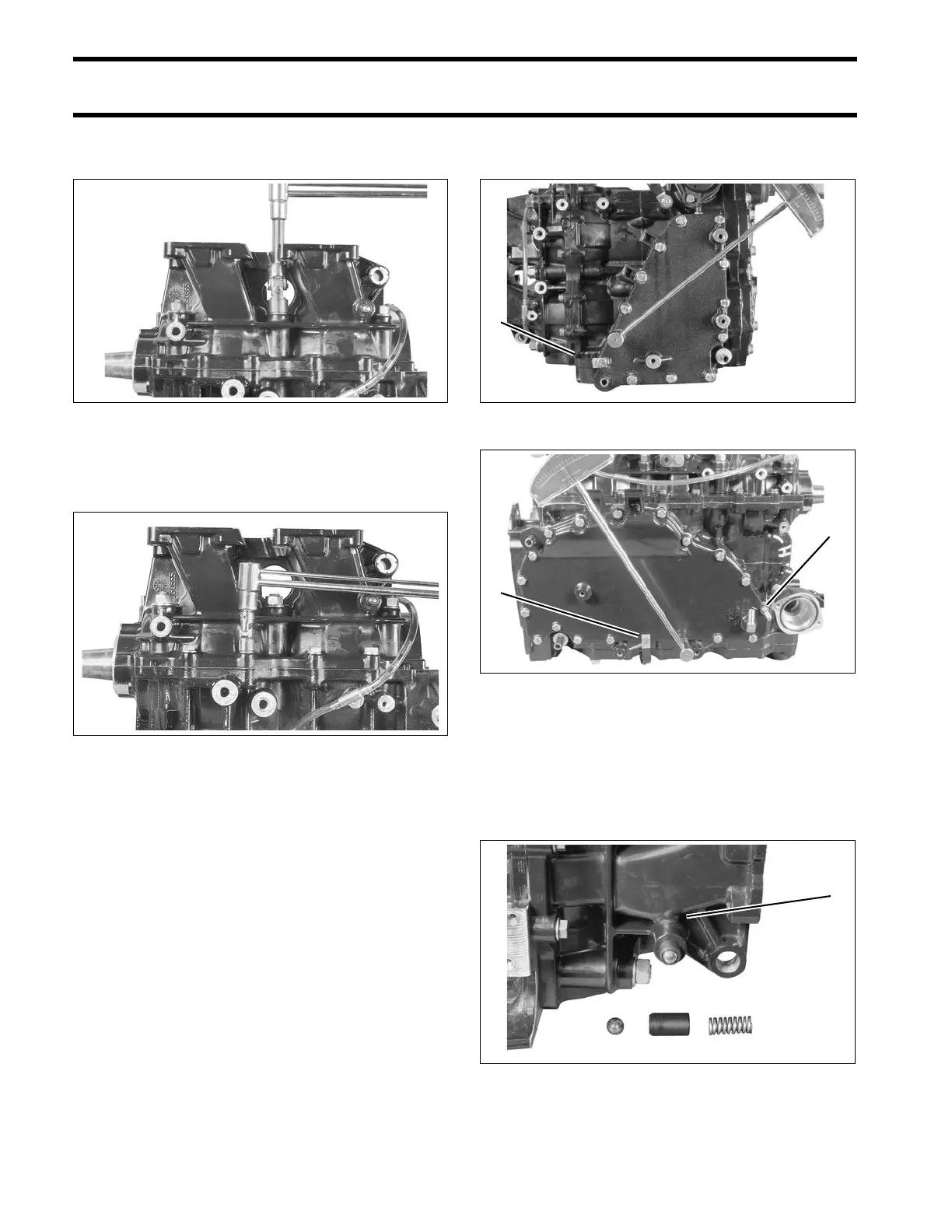

Shift Linkage Installation

Place the spring, guide, and ball of the shift detent

assembly into the crankcase. Lubricate with Tri-

ple-Guard grease.

002254

002259

2-Cylinder models

1. J-clamp

002242r

3-Cylinder models

1. Double-ended stud

2. J-clamp

002122

1. Shift detent assembly 002135

Loading...

Loading...