215

POWERHEAD

POWERHEAD ASSEMBLY

10

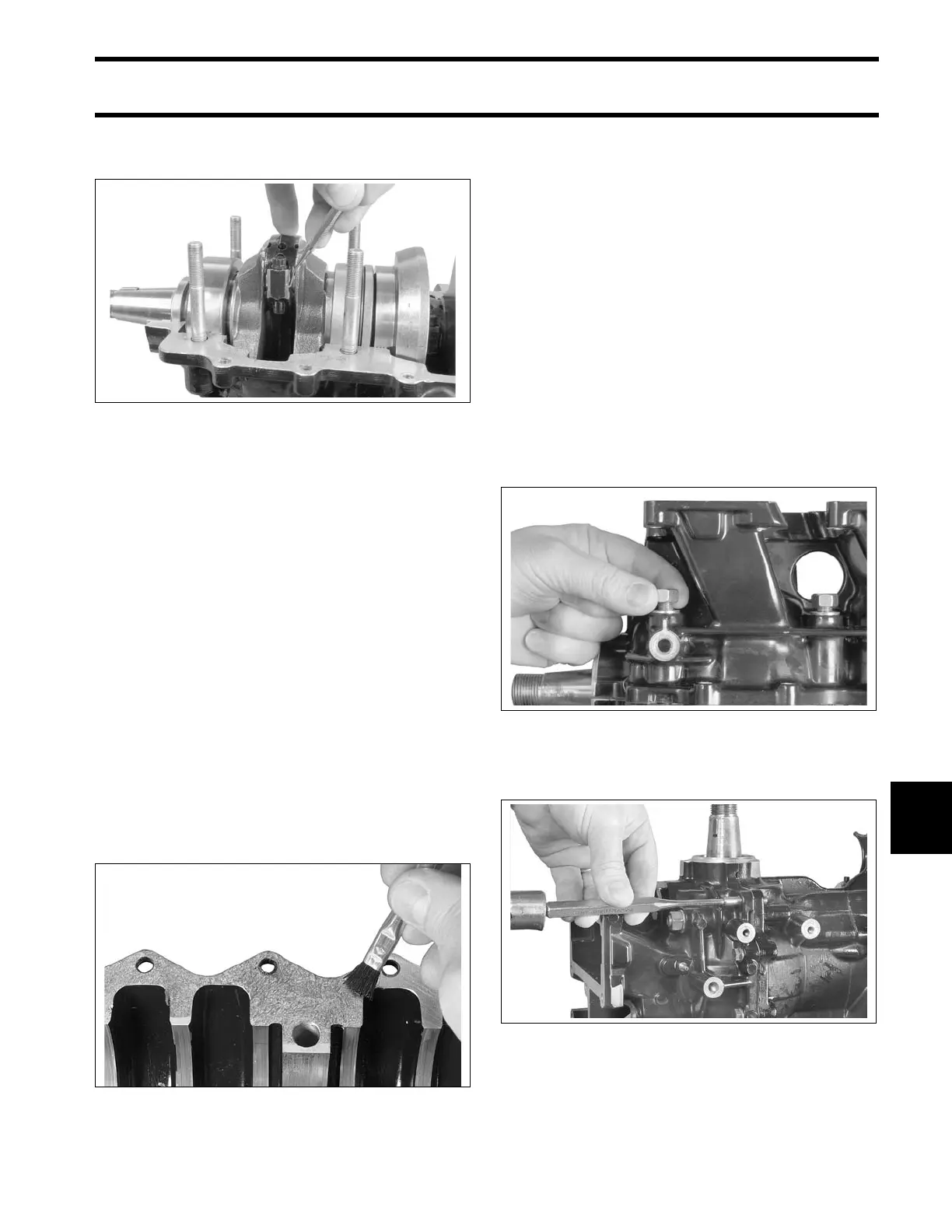

Test at least three corners of the rod and cap joint

with a pick. Joint must be smooth with no step.

Crankcase Assembly

Make sure crankshaft is still seated on dowel pins

before assembling crankcase.

Thoroughly clean and degrease the mating

flanges of the crankcase and cylinder block with a

non-petroleum based solvent, such as isopropyl

alcohol or acetone, and let air dry.

IMPORTANT: DO NOT allow solvent to get on

internal components. Clean only the mating

flanges.

Apply Gasket Sealing Compound to lower oil seal

groove in crankcase. DO NOT put any sealer in

upper seal groove.

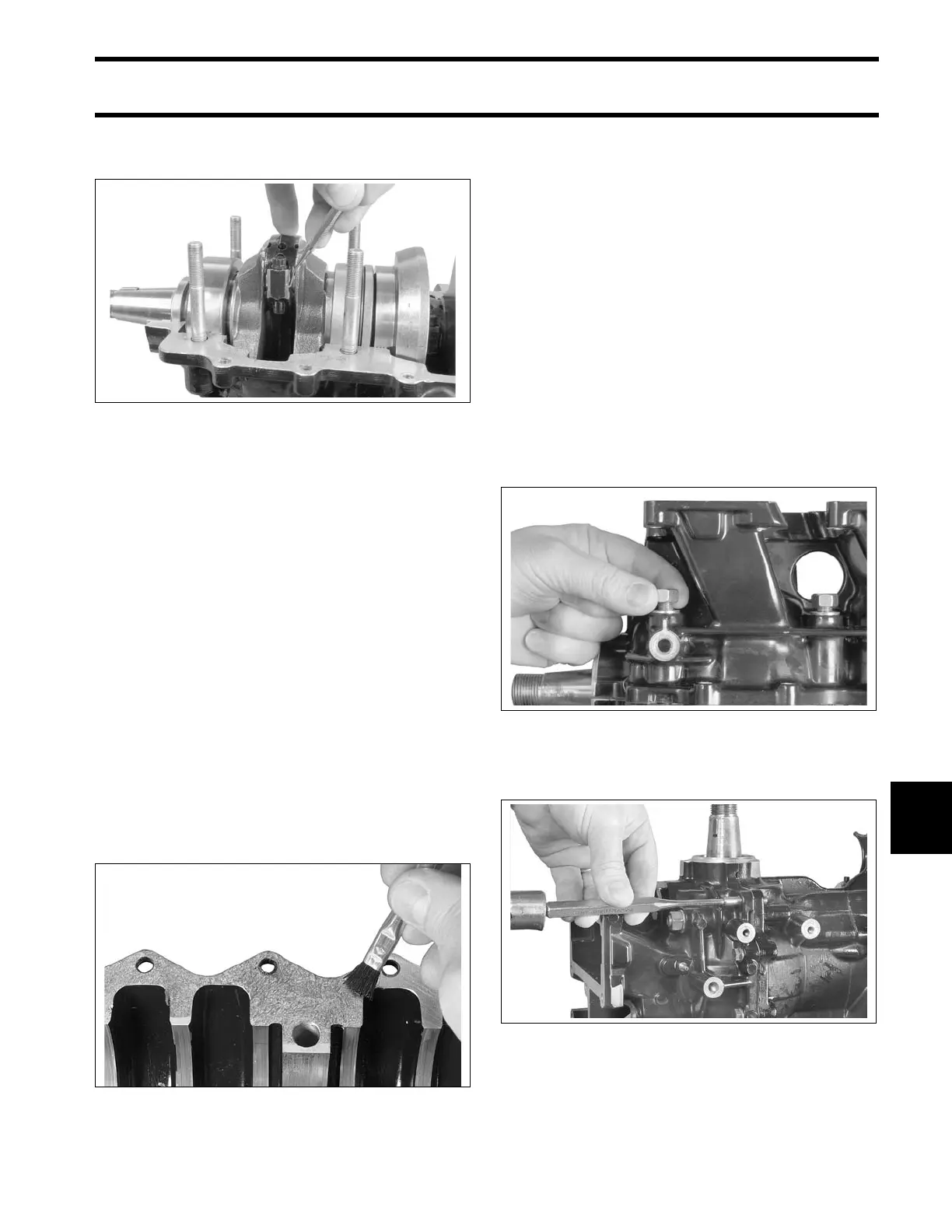

Use a small brush with a tapping motion to apply a

thin, even coat of Gel-Seal II sealant to the crank-

case mating flange. The sealer must not come

within 1/4 in. (6.4 mm) of bearings.

IMPORTANT: Gel-Seal II has a shelf life of at

least one year when stored at room temperature.

Test the Gel-Seal II or replace it if the age of the

tube cannot be determined. Using old Gel-Seal II

could cause crankcase air leaks.

IMPORTANT: The use of Locquic Primer is NOT

recommended. If primer is used, crankcase

halves must be assembled and tightened within

ten minutes after the Gel-Seal II has been applied.

Lower the crankcase into place. Make sure that

upper oil seal and lower seal housing are seated

in grooves.

Apply outboard lubricant to the main bearing

studs. Install nuts and washers finger tight, no

more than 60 in. lbs. (7 N·m).

When the crankcase is seated, install and firmly

seat the crankcase taper pin.

Tighten main bearing nuts in stages to a final

torque of:

• 26 to 30 ft. lbs. (35 to 41 N·m).

002117

TYPICAL 003874

002271

002260

Loading...

Loading...