313

GEARCASE SERVICE, 40 – 60 HP MODELS

GEARCASE ASSEMBLY

12

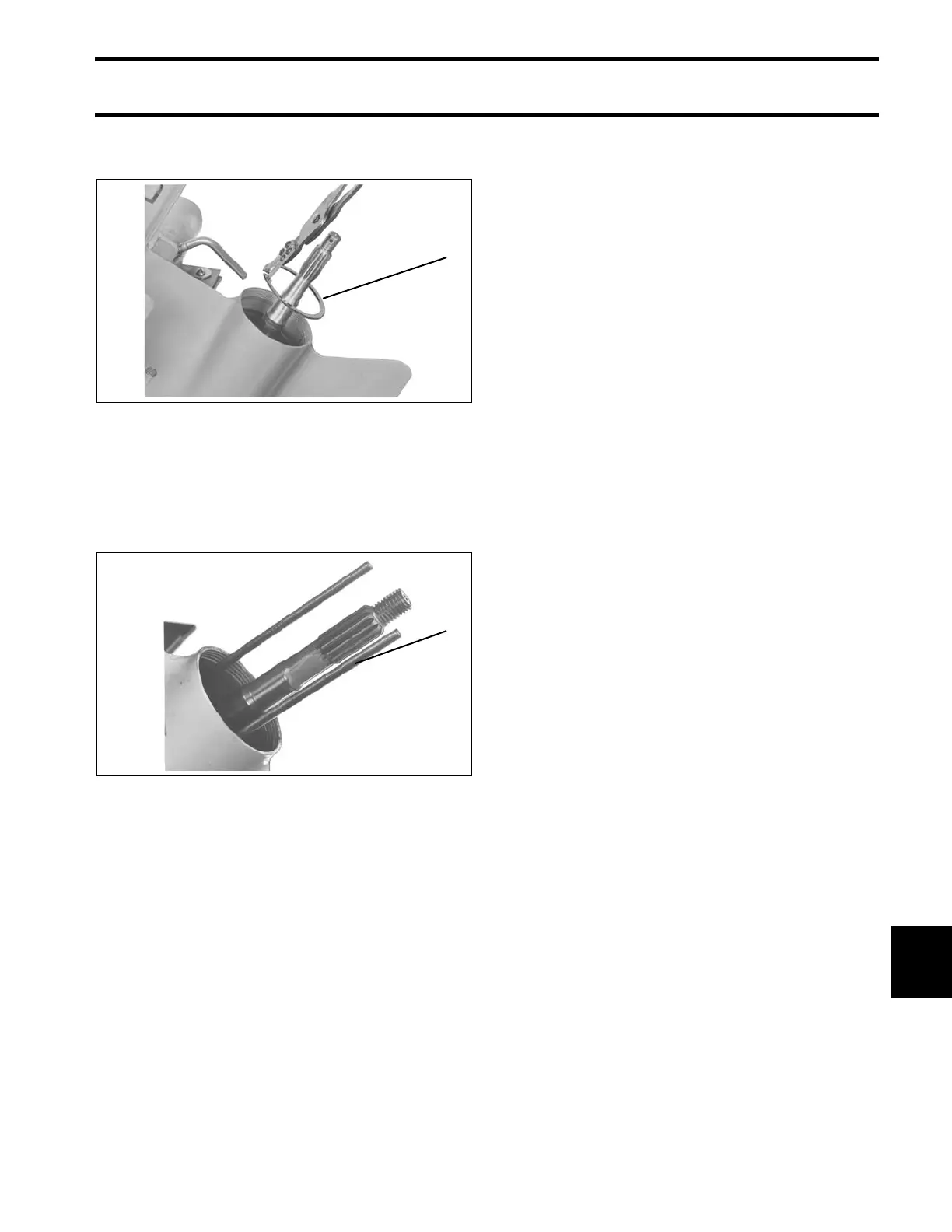

Make sure the retaining rings are seated in the

grooves in the gearcase.

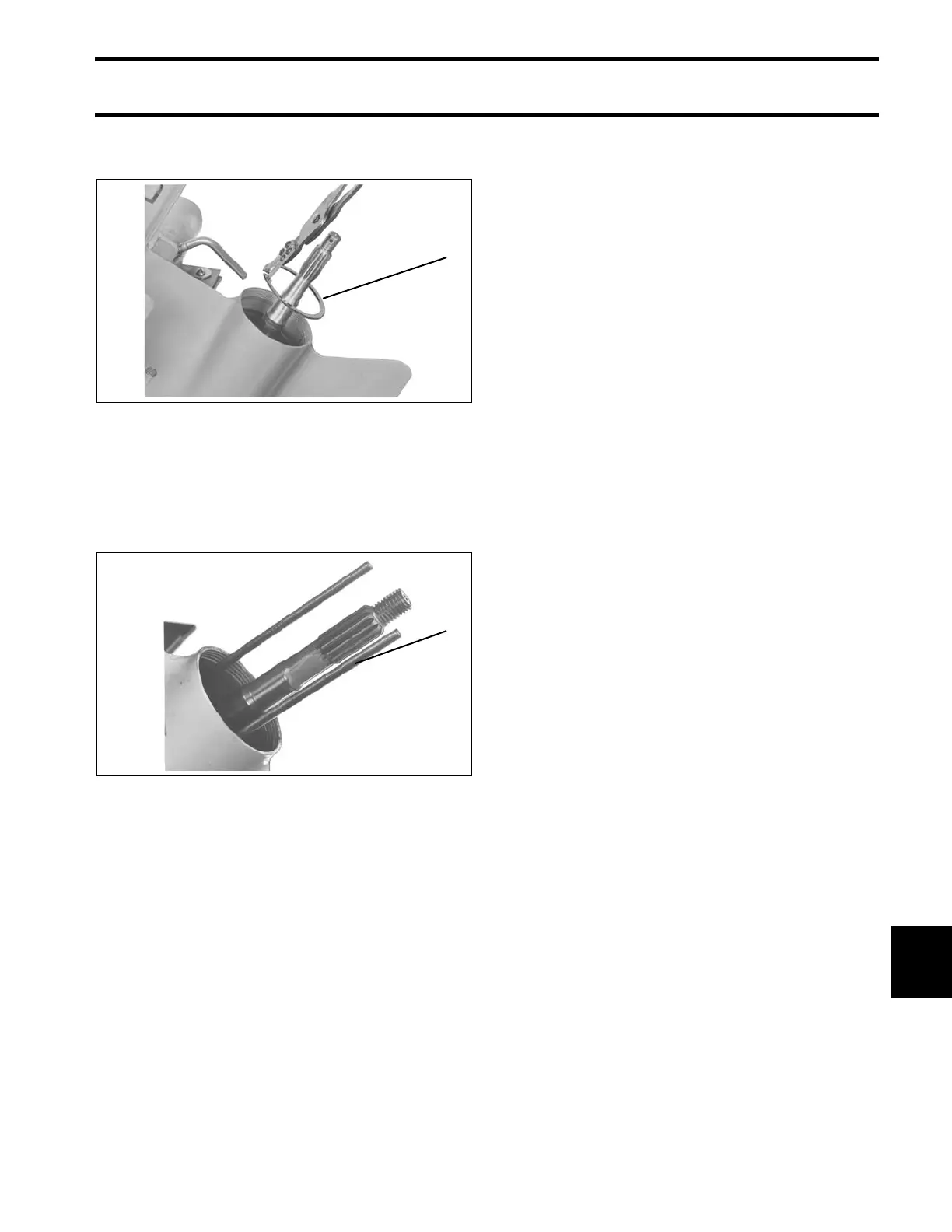

Thread two Guide Pins, P/N 383175, into the

retainer plate to align holes in the plate with holes

in the propeller shaft bearing housing. Do not

thread guide pins more than two turns into the

retainer plate.

Install O-ring in groove in the bearing housing.

Lightly apply Gasket Sealing Compound to the

O-ring flange and aft support flange of the bearing

housing. Do not allow sealer to contact either for-

ward thrust surface or bearings in the housing.

Align the bearing housing on the guide pins with

the word “UP” toward the top. Place the housing

into gearcase and tap the housing with a soft face

mallet to seat the O-ring.

Apply Gasket Sealing Compound to the threads

and seals of the four propeller housing retaining

screws. Install two of the screws into the bearing

housing finger tight. Remove the guide pins and

install the remaining two screws. Tighten all four

screws to a torque of 120 to 140 in. lbs. (14 to 16

N·m).

Final Assembly and Adjustment

To complete gearcase assembly, refer to:

• GEARCASE LEAK TEST on p. 291

• WATER PUMP SERVICE on p. 294

• SHIFT ROD ADJUSTMENT on p. 296

• GEARCASE REMOVAL AND INSTALLATION

on p. 292

• Gearcase Lubricant on p. 43

• Propeller Hardware Installation on p. 290

• Trim Tab Adjustment on p. 35.

During break-in period of a reassembled

gearcase, change the gearcase lubricant between

10 to 20 hours of operation.

1. Retaining ring 9438

1. Guide pin COA3550

Loading...

Loading...