308

GEARCASE SERVICE, 40 – 60 HP MODELS

DRIVESHAFT SHIMMING

DRIVESHAFT SHIMMING

If a new pinion gear is needed,

replace gear set before shimming.

Pinion gear backlash is adjusted by using shims

between the driveshaft bearing housing and the

thrust washer. When installing a new thrust bear-

ing or washer, bearing housing, pinion, or drive-

shaft, it is necessary to properly shim the

assembly to restore the correct clearance.

Use Driveshaft Shimming Tool, P/N 5005925.

Shim gauge bars are precision made and should

be handled carefully. The length of each bar is

stamped near the part number. This dimension is

0.020 in. (0.508 mm) shorter than the actual

shimmed length of the driveshaft.

IMPORTANT: Clean pinion and driveshaft

before assembly. Replace any damaged parts.

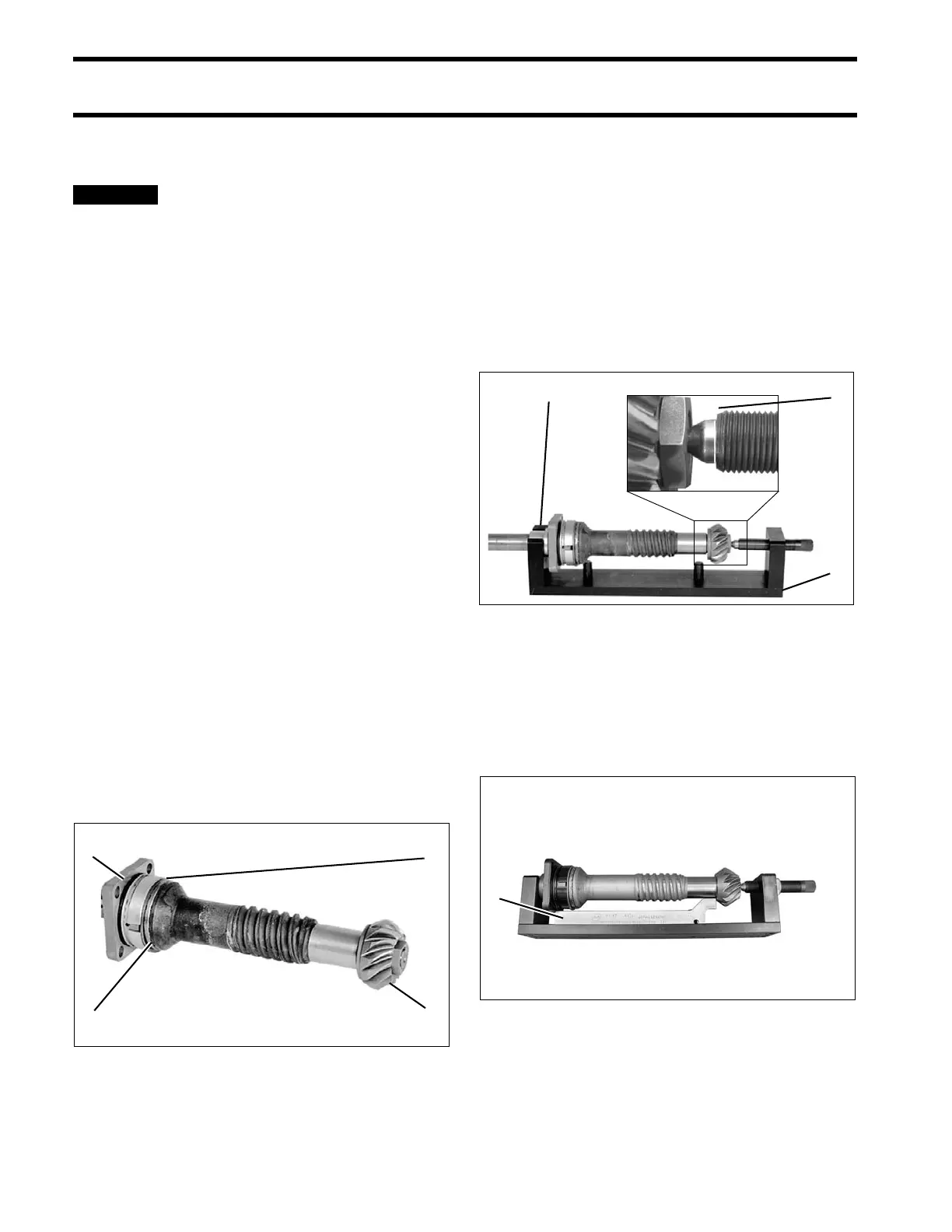

Assemble the driveshaft bearing housing, thrust

washer, thrust bearing, and pinion onto the drive-

shaft. Use Driveshaft Seal Protector, P/N 312403,

when installing or removing the bearing housing.

Lightly coat the threads of the pinion nut with out-

board lubricant and tighten to a torque of 40 to 45

ft. lbs. (54 to 60 N·m).

IMPORTANT: The original pinion nut may be

used for shimming, but must NOT be used in final

assembly.

Select correct collar and shim gauge bar:

• Collar: P/N 328363

• Shim gauge bar: P/N 328366

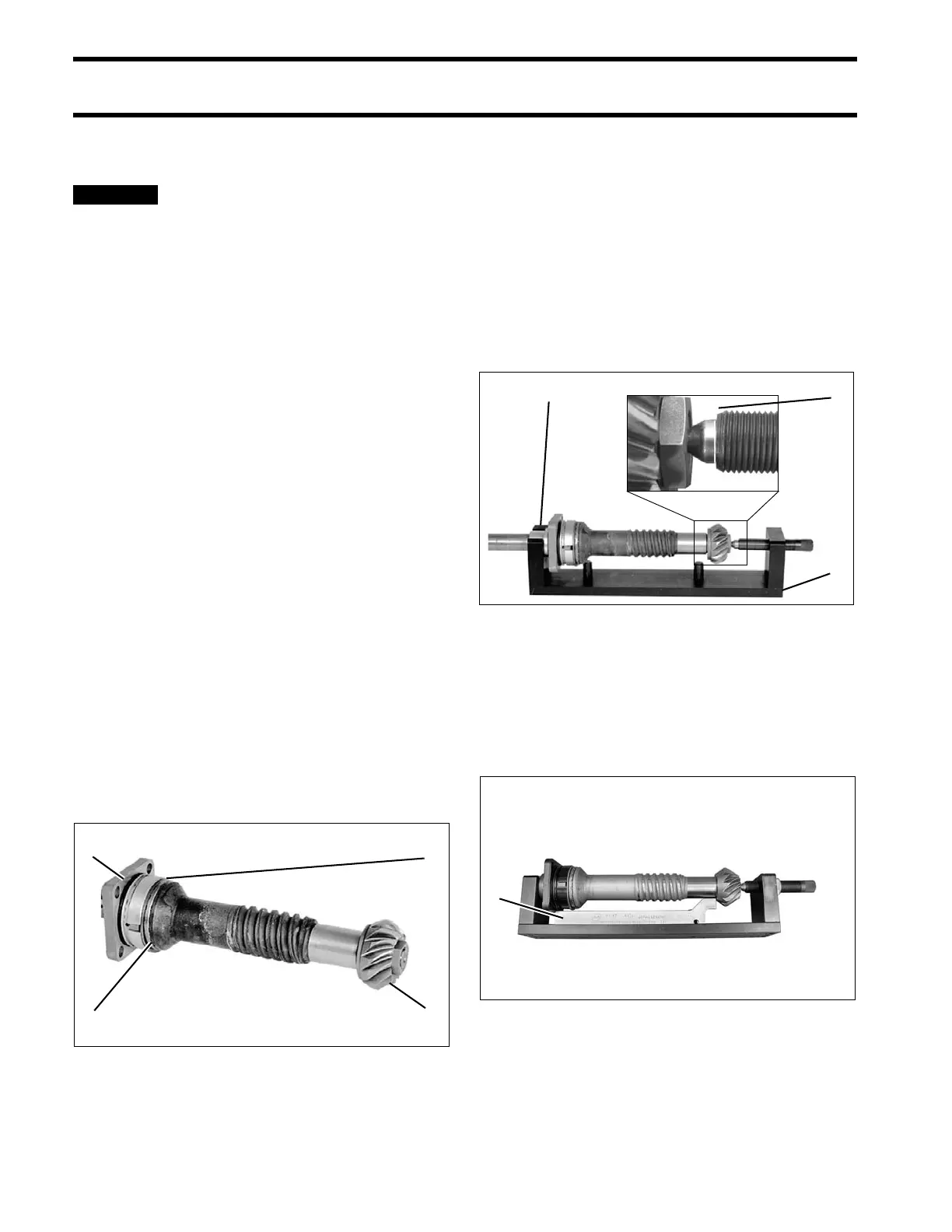

Slide the collar onto the driveshaft with large end

in contact with the bearing housing.

Insert the assembled driveshaft into the tool base

and tighten preload screw against the driveshaft

until groove on the spring-loaded plunger is flush

with end of threads. Tighten locking ring on pre-

load screw.

Rotate the driveshaft several revolutions to seat

bearings.

Lay the tool base on its side. Place the shim

gauge bar against guide pins of the tool base.

Check squareness of the bearing housing mount-

ing surface by holding the shim gauge bar against

the pinion while rotating just the bearing hous-

ing. Use a feeler gauge to measure clearance

1. Driveshaft bearing housing

2. Thrust washer

3. Thrust bearing

4. Pinion

COA3565

1. Collar

2. Tool base

3. Groove

COA3566

DSC00326

1. Shim gauge bar 005416

Loading...

Loading...