214

POWERHEAD

POWERHEAD ASSEMBLY

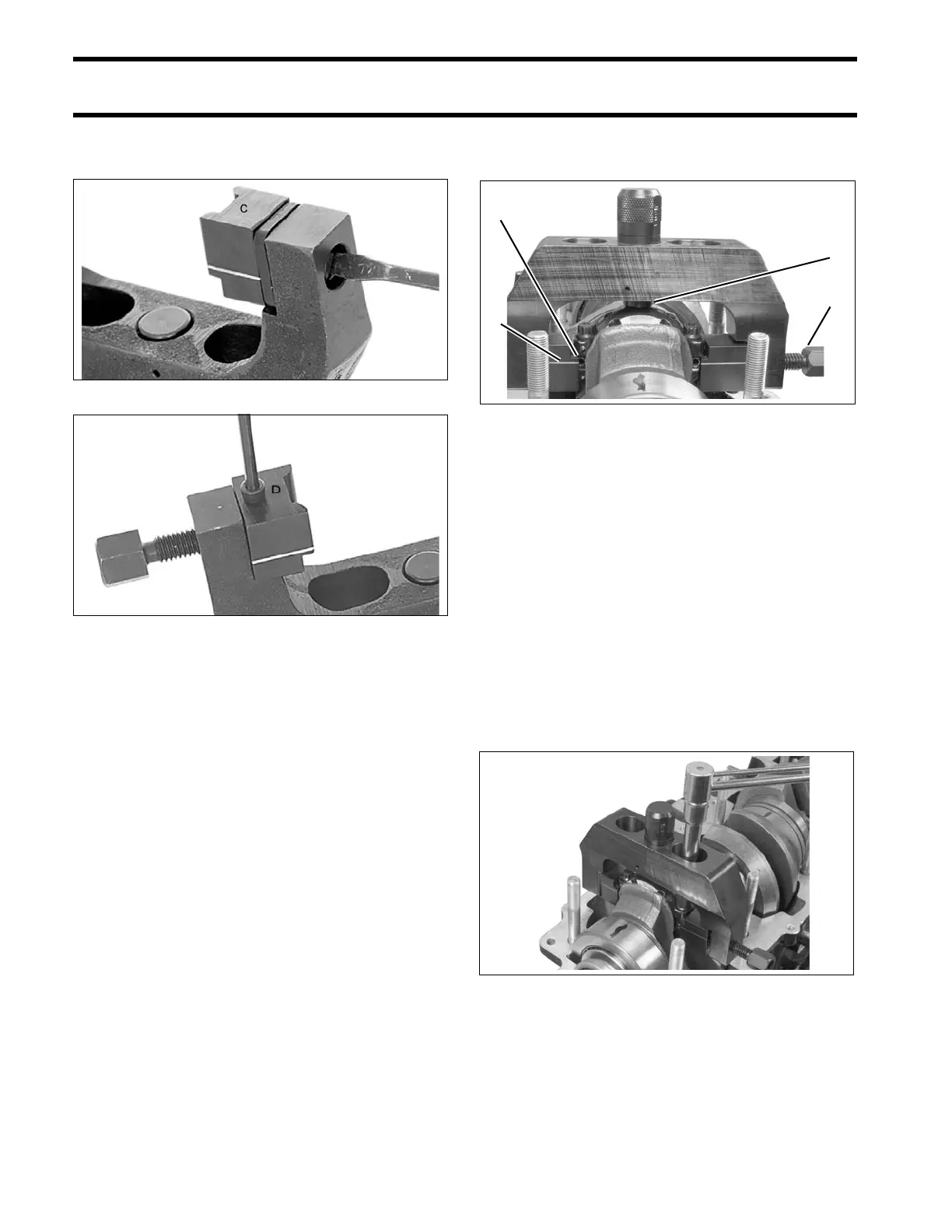

Secure restraining jaw “C” and forcing jaw “D” to

frame.

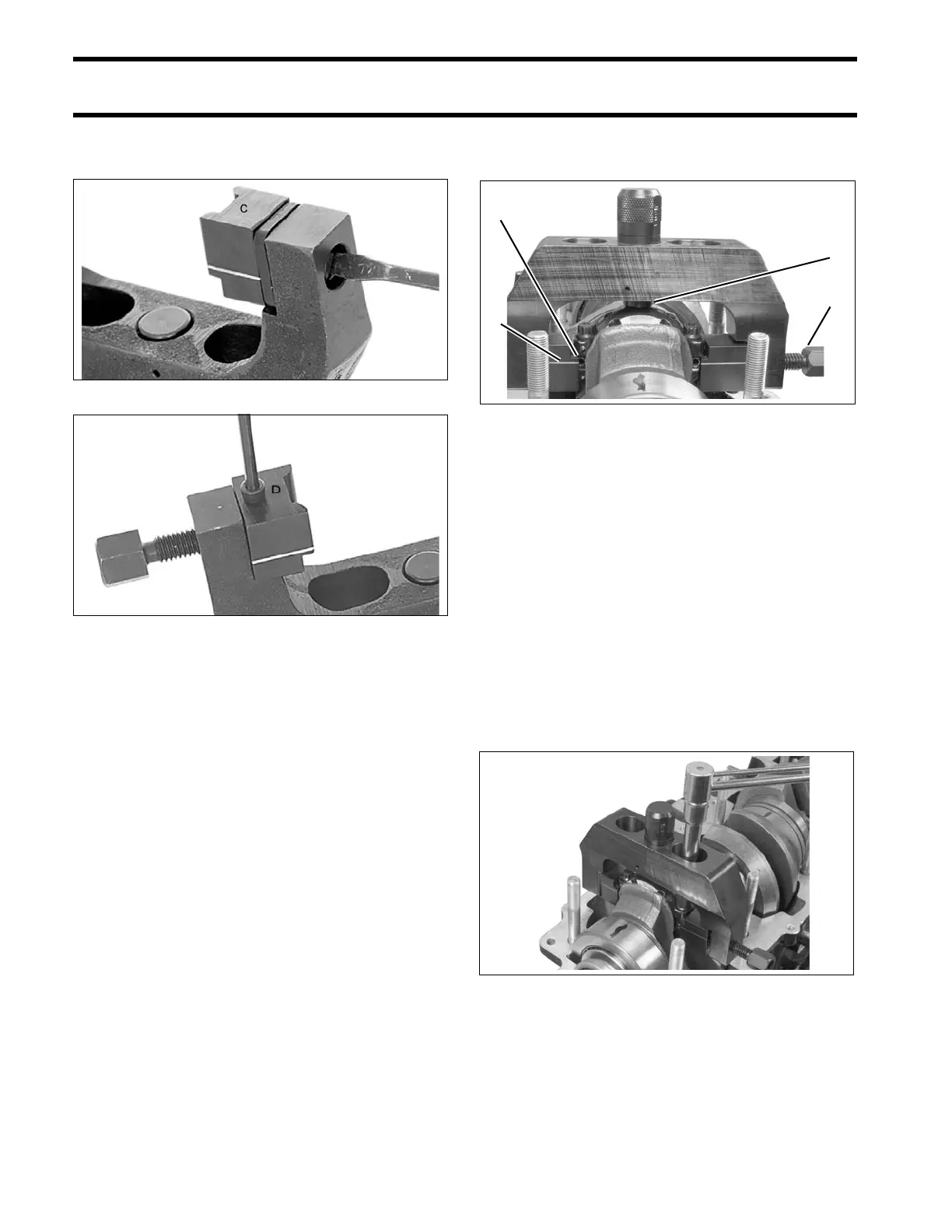

Apply a light coat of outboard lubricant to the cor-

ners of the connecting rod and rod cap. Place

frame on connecting rod using the following pro-

cedure.

• Place frame onto the connecting rod so the con-

tact area of the jaw is centered on the side of

the rod.

• Tighten forcing screw until jaws contact con-

necting rod.

• Slide frame down until adjustment stop contacts

the rod cap. The groove lines on the jaws must

be centered on the rod/crankpin diameter.

• Tighten the forcing screw to a torque of 14 to 16

in. lbs. (1.6 to 1.8 N·m).

IMPORTANT: Make sure that frame is squarely

in position and that rod and cap are aligned.

Loosen both rod cap screws one-quarter turn.

Use Torquing Socket, P/N 331638, to tighten rod

cap screws in three stages:

• Apply first torque of 40 to 60 in. lbs. (5 to 7 N·m)

to both rod cap screws.

• Tighten screws to a torque of 14 to 16 ft. lbs. (19

to 21.7 N·m).

• Apply final torque of 30 to 32 ft. lbs. (41 to 43

N·m).

IMPORTANT: If a new screw is used, it must be

installed as above. Then, it must be removed, re-

lubricated, and installed again.

Loosen forcing screw and remove the frame.

Restraining Jaw “C” 21591

Forcing Jaw “D” 21594

1. Contact area of jaw

2. Forcing screw

3. Adjustment stop

4. Groove line

002071

002072

Loading...

Loading...