315

GEARCASE SERVICE, 75 – 90 HP MODELS

GEARCASE REMOVAL AND INSTALLATION

12

Gearcase Installation

Before installing gearcase, shift rod

adjustment MUST be checked. Refer to SHIFT

ROD ADJUSTMENT on p. 319.

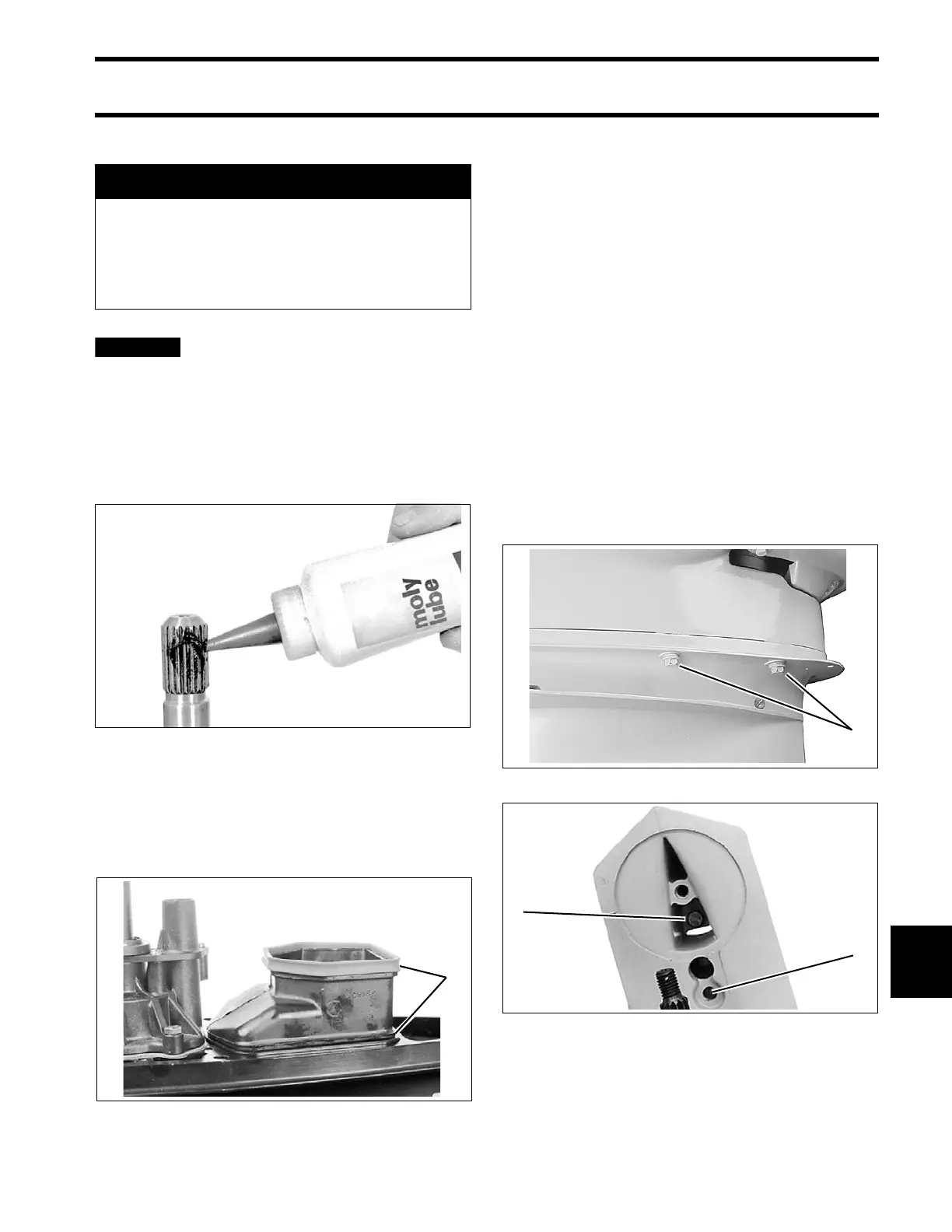

Coat the driveshaft splines with Moly Lube. DO

NOT coat top surface of the driveshaft because

lubricant may prevent seating of the driveshaft in

the crankshaft.

Apply Adhesive 847 to the lower exhaust housing

seals’ inner surfaces. Place two new seals on the

housing. Apply Triple-Guard grease to the seals’

outer surfaces and place the housing on the

gearcase.

Slide the gearcase into place, making sure:

• Driveshaft engages the crankshaft.

• Water tube enters the water pump.

• Lower inner exhaust housing installs correctly.

• Shift rod does not turn and is positioned prop-

erly in the shift rod lever below the crankcase.

IMPORTANT: New gearcase screws are treated

with a thread-locking material. Apply Triple-Guard

grease to threads to ensure that the correct

clamping force is achieved when tightening—If a

previously installed screw is re-used, use a wire

brush to remove any old thread-locking material or

corrosion and lubricate threads with Triple-Guard

grease.

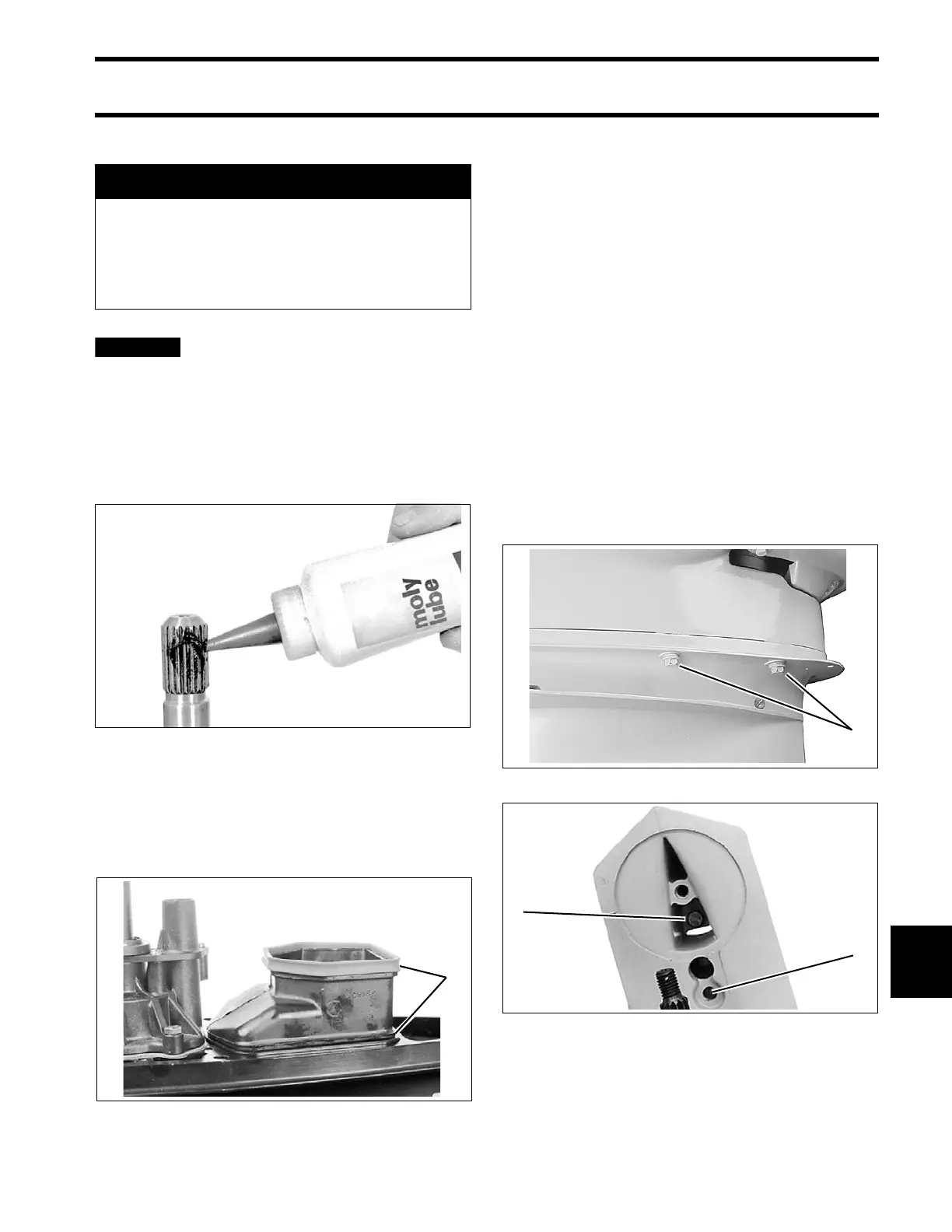

Install screws and washers and tighten to a torque

of:

• 3/8 in. screws – 26 to 28 ft. lbs. (35 to 38 N·m)

• 7/16 in. screws – 45 to 50 ft. lbs. (61 to 68 N·m)

A WARNING

During service, the outboard may drop

unexpectedly. Avoid personal injury;

always support the outboard’s weight with

a suitable hoist or the tilt support bracket

during service.

30385

1. Lower exhaust seals 32002

1. 3/8 in. screws 001990

1. 3/8 in screw

2. 7/16 in. screw

COA3139

Loading...

Loading...