39

Pneumatic Installation

Settings of the ow-rate or the control speed with the help of the ow restriction

screws:

For proper setting, it is advisable to turn the twoowrestrictionscrewsinitiallyintotheminimum

ow-rateposition. The process valve will then initially move slowly so that you have more time to

ndtheoptimumsettingduringaswitchingoperation.

Minimisingtheowrate: Turnclockwise

Maximisingtheowrate: Turncounterclockwise

→ Open the housing following the instructions in chapter “8OpeningandClosingtheHousing”.

→ Observingthesafetyguidelines,activatetherespectivevalvelocation(V1,V2orV3)tobeset(either

usingthesystemcontrol(PCserviceprogrammorBürkertCommunicator)ortherespectivemanual

overrides on the solenoid valve - “Fig.13”).

→ Turntheowrestrictionscrew"P"counterclockwisetosettherequiredowrateandthereforethe

openingtimefortheprocessvalve.(Tool:at-bladescrewdriver,width≤3mm).

→ Subsequentlydeactivatetherespectivevalvelocation(V1,V2orV3).

→ Turntheowrestrictionscrew"R"counterclockwisetosettherequiredowrateandthereforethe

closing time for the process valve.

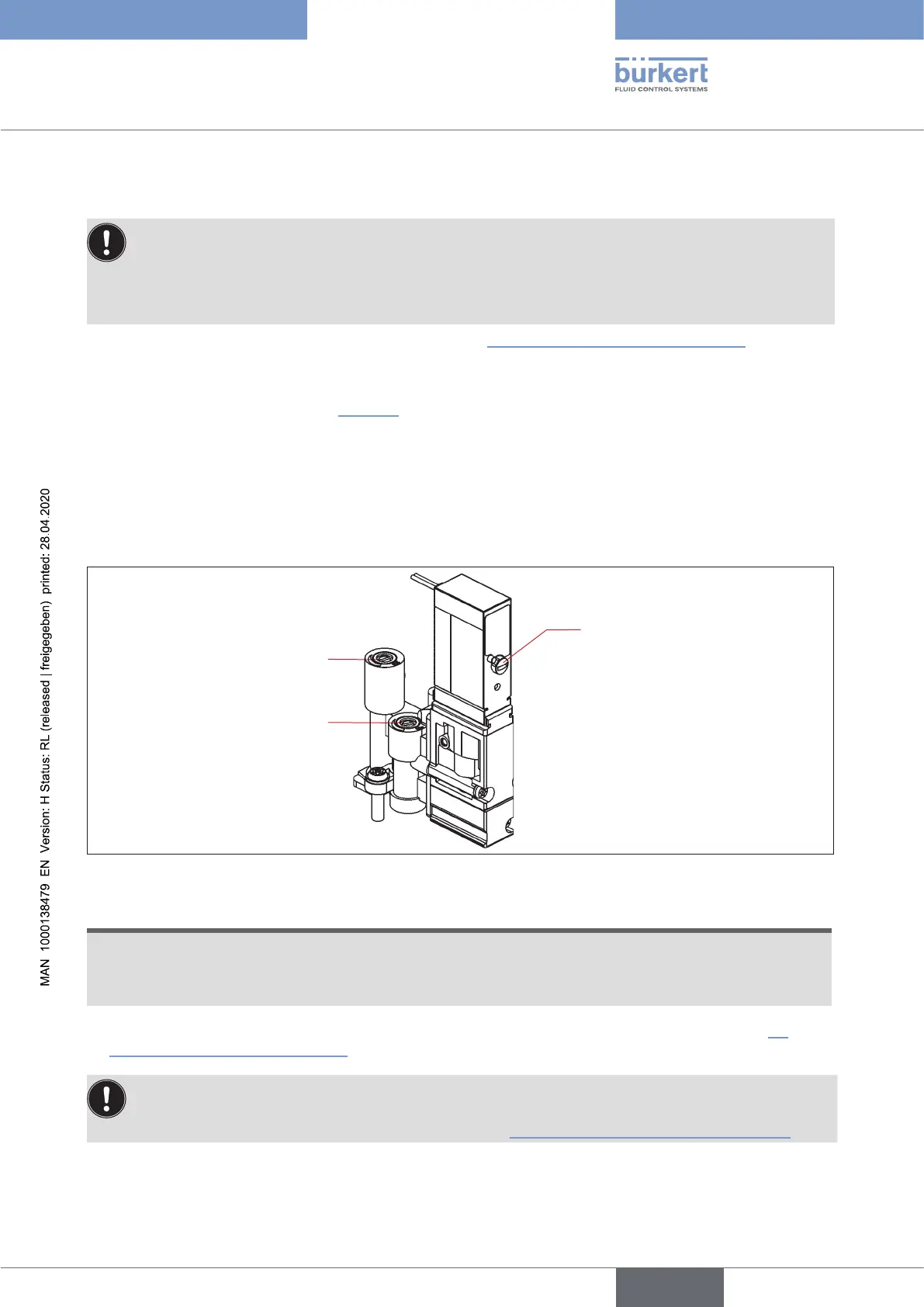

Flow restriction screw

Exhaust air R

Flow restriction screw

Intake air P

Red hand lever of the

mechanical manual

override:

Hand lever position:

left: 0

right: 1

Fig. 13: Flow restriction screws and mechanical manual override of the solenoid valves

NOTE!

To avoid unintentional switching of the process valve:

•

Makessurethatallmanualoverrideshavebeendeactivated(handleverallthewayleft,aspictured)

after the setting work has been completed!

→ Ifnofurtherinstallationworkisrequired,closethehousingfollowingtheinstructionsinchapter“8

OpeningandClosingtheHousing”.

If no system status is available during setting, readjust the system under system operation conditions

if necessary.

Observe the safety guidelines during this! See chapter

“3BasicSafetyInstructions”onpage12.

english

Control Head Type 8681

Loading...

Loading...