C-9

Scanner

®

2000 microEFM Appendix C

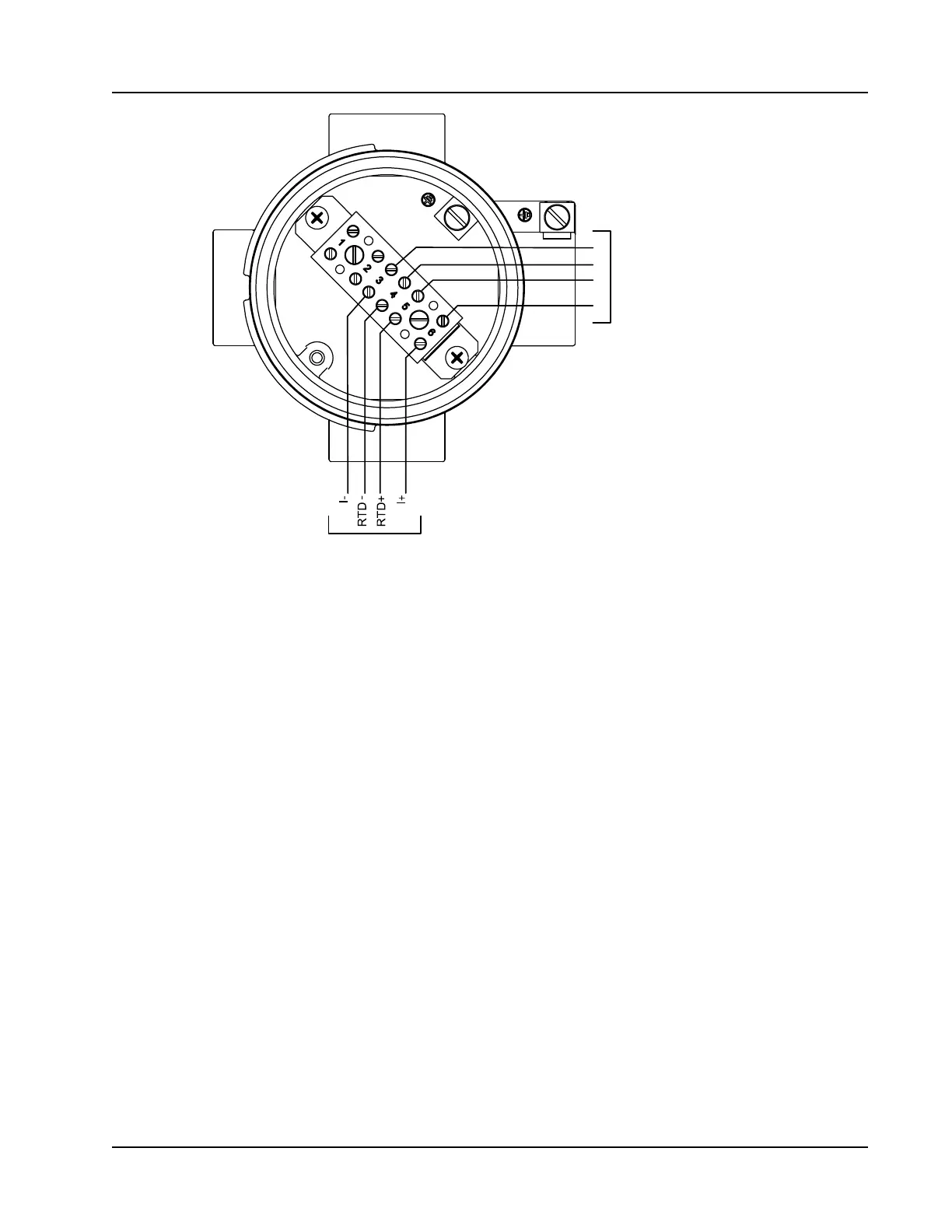

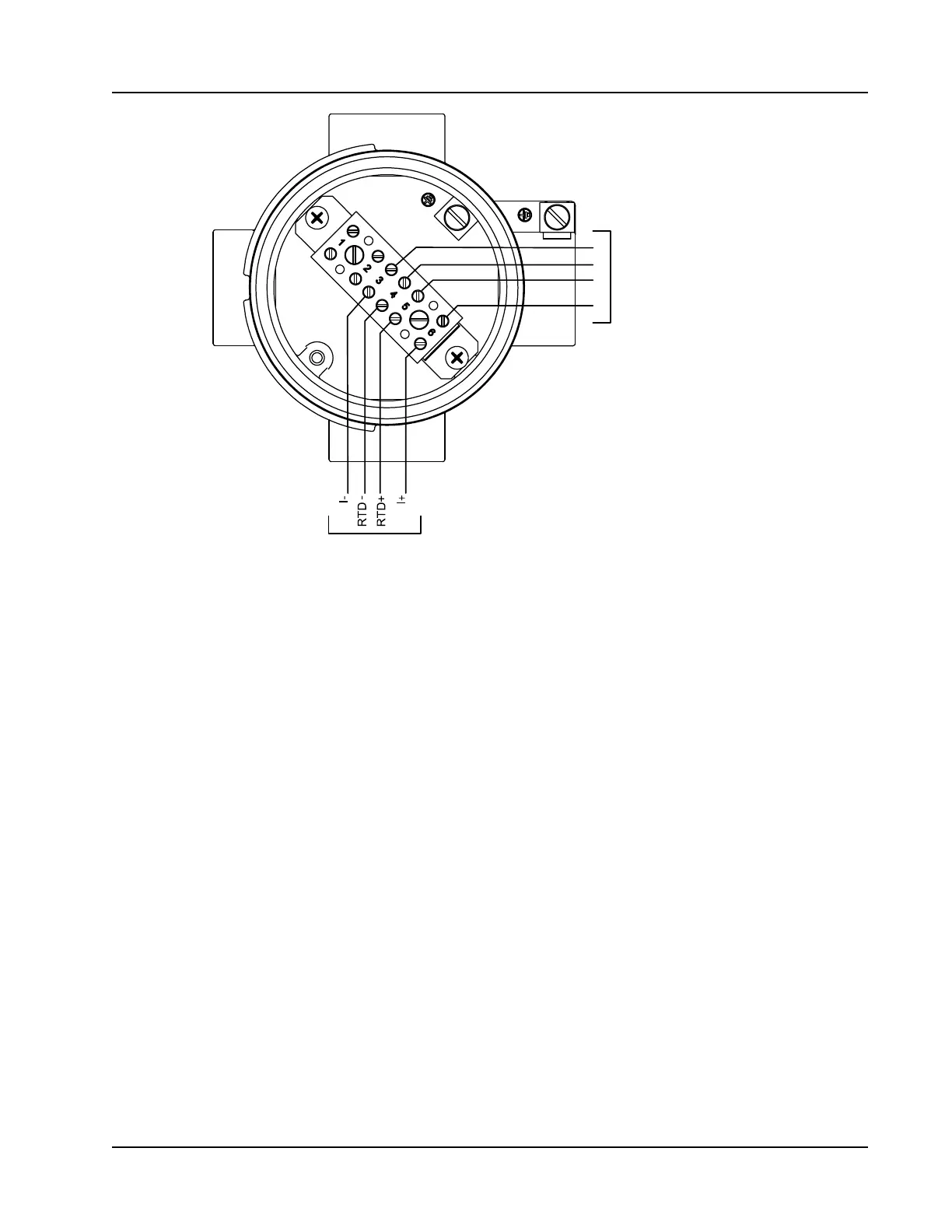

TO SCANNER 2000

MAIN BOARD,

TB1, TERMINALS 1-4

JUNCTION BOX

(OPTIONAL)

FROM RTD

(4-WIRE

RECOMMENDED)

Figure C.7— Foundation™ eldbus process temperature input wiring with junction box

Device Conguration

Basic parameters such as communications port slave address and baud rate, date and time, contract hour, and

plate size can be congured from the device keypad (Conguration via Keypad, page 70). All other parameters

must be congured using the ModWorX Pro software provided with the purchase of a Scanner 2000.

Foundation™ eldbus conguration is performed with a customer-supplied conguration tool. For

basic instructions for conguring the function blocks that are integral to the Scanner 2000, see Fieldbus

Conguration below.

Fieldbus Conguration

At the core of the Scanner 2000 is an electronics package that measures and computes standard volumes of

gas, steam, petroleum liquids, and generic liquids with a high degree of accuracy and with very low power

consumption. These electronics communicate via RTU Modbus

®

.

The Scanner 2000 for

Foundation™ Fieldbus expands those capabilities to allow communication with

devices on a eldbus network using Foundation™ eldbus H1 protocol. In addition to its native Modbus

®

communications, the Scanner 2000 publishes values for four process variables to a Foundation

™

eldbus

network using an integrated eldbus module.

The process variable values are written to a transducer block within the eldbus module. When the process

variables are mapped to analog input blocks within the eldbus module, those variable inputs are published to

the network and made available for development of process control strategies.

Loading...

Loading...