59

Scanner

®

2000 microEFM Section 2

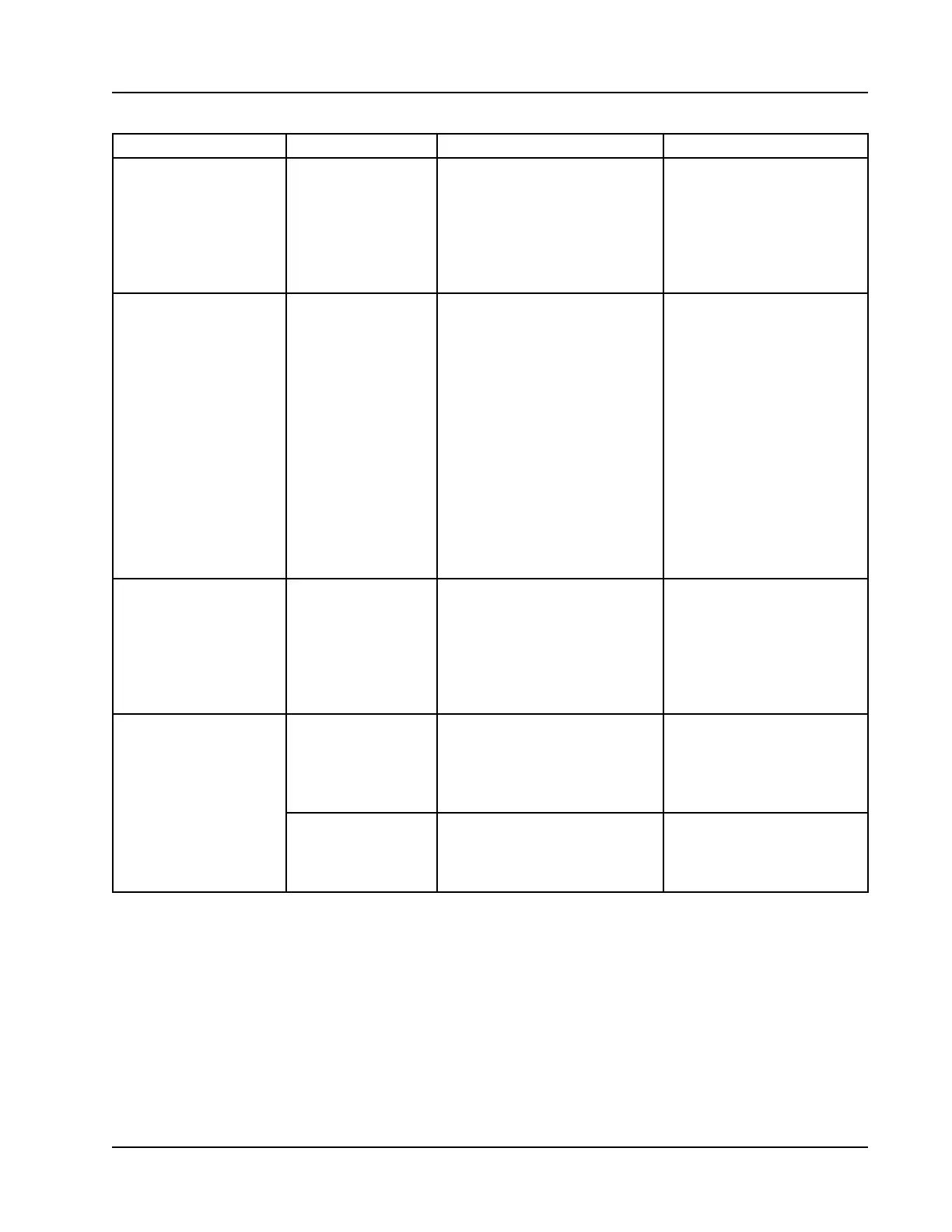

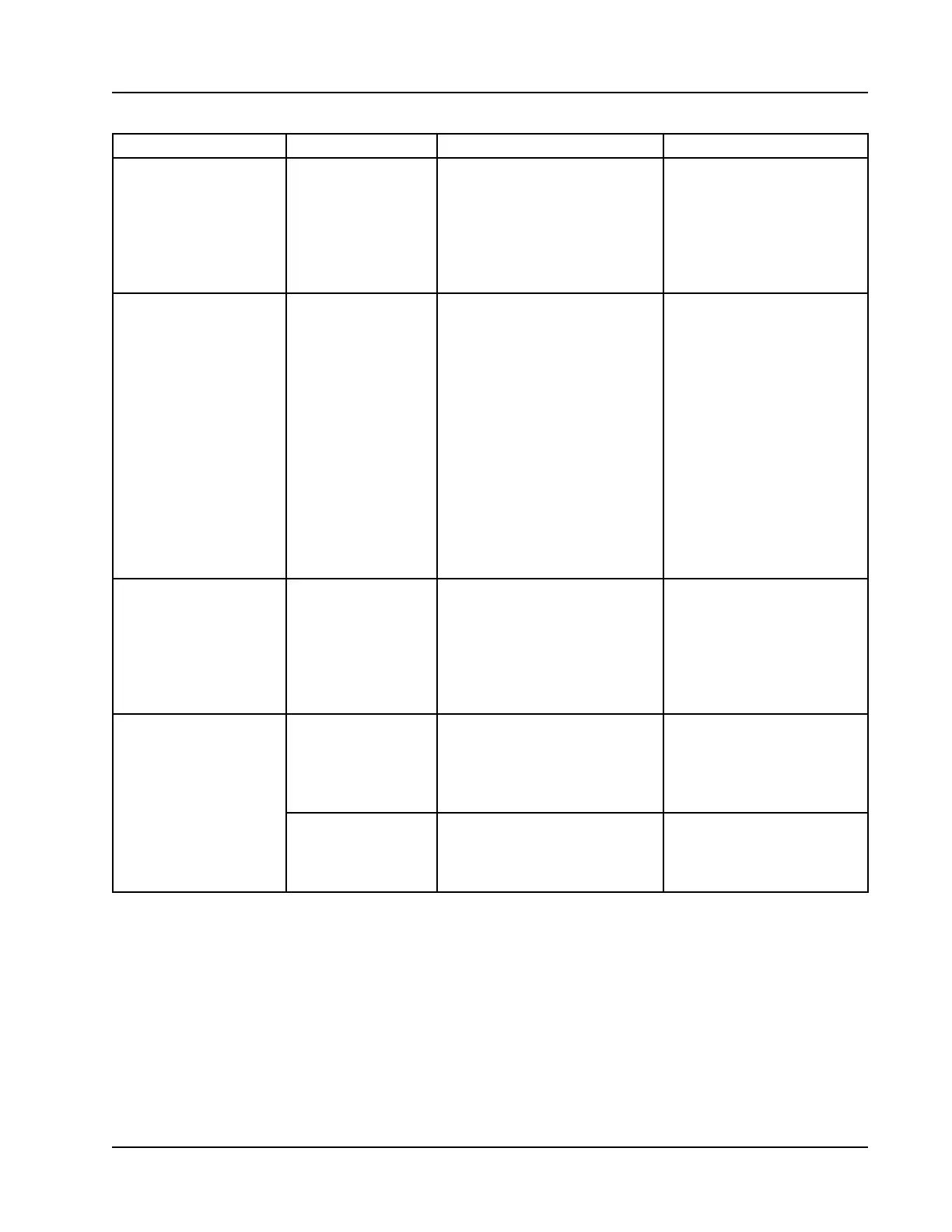

Table 2.2—Industry Standards for Orice Meters

Standard Applicable Section Description Notes

AGA Report No. 3:

Orice Metering of

Natural Gas and Other

Related Hydrocarbon

Fluids

Part 2: Specication

and Installation

Requirements,

Section 2.6

(Installation

requirements)

Specications for orice

meters (to include beta ratios)

Installation requirements for

orice plates, meter tubes, ow

conditioners, and thermometer

wells

This standard is also

distributed under the

following names: API

MPMS Chapter 14.3, Part

2; ANSI/API 14.3, Part

2-2000; and GPA 8185,

Part 2.

ISO 5167:

Measurement of Fluid

Flow by Means of

Pressure Differential

Devices Inserted in

Circular Cross-Section

Conduits Running Full

Part 1: General

Principles and

Requirements

Installation of orice plates

inserted into a circular cross-

section conduit running full

Limitation of pipe size and

Reynolds number

ISO 5167 is applicable

only to ow that remains

subsonic throughout the

measuring section and

where the uid can be

considered single-phase.

It is not applicable to the

measurement of pulsating

ow. It does not cover the

use of orice plates in pipe

sizes less than 50 mm

(2 in.) or more than 1000

mm (39 in.), or for pipe

Reynolds numbers below

5000.

ISO 5167:

Measurement of Fluid

Flow by Means of

Pressure Differential

Devices Inserted in

Circular Cross-Section

Conduits Running Full

Part 2: Orice

Plates

Species orice plates that can

be used with ange pressure

tappings, corner pressure

tappings, D and D/2 pressure

tappings.

API Manual

of Petroleum

Measurement

Standards, Chapter

21.1 (Electronic Gas

Measurement)

Section 1.7

-Equipment

Installation

Installation of electronic gas

measurement devices and

associated communications,

gauge/impulse lines, and

cabling

Section 1.8

-Equipment

Calibration and

Verication

Requirements for calibrating

and verifying the accuracy of

electronic gas measurement

devices

Industry Standards for Cone Meters

For installation requirements for use with a cone meter and applicable ow rate calculations, see the NuFlo

Cone Meter User Manual, Part No. 9A-85165000.

Loading...

Loading...