47

Scanner

®

2000 microEFM Section 2

practices listed above.

• Position the cone meter so that there are zero to ve pipe diameters upstream of the meter and zero to

three pipe diameters downstream of the meter.

• Install the meter so that the static pressure tap is upstream of the differential pressure tap. The high side of

the integral Scanner 2000 sensor must also be situated upstream.

• Install shut-off valves directly on the DP meter pressure taps. Choose a shut-off valve that is rated for the

ambient temperatures of the location and the operating pressure of the pipe in which it will be installed,

and for use with dangerous or corrosive uids or gases, if applicable. The valves must not affect the trans-

mission of the differential pressure signal.

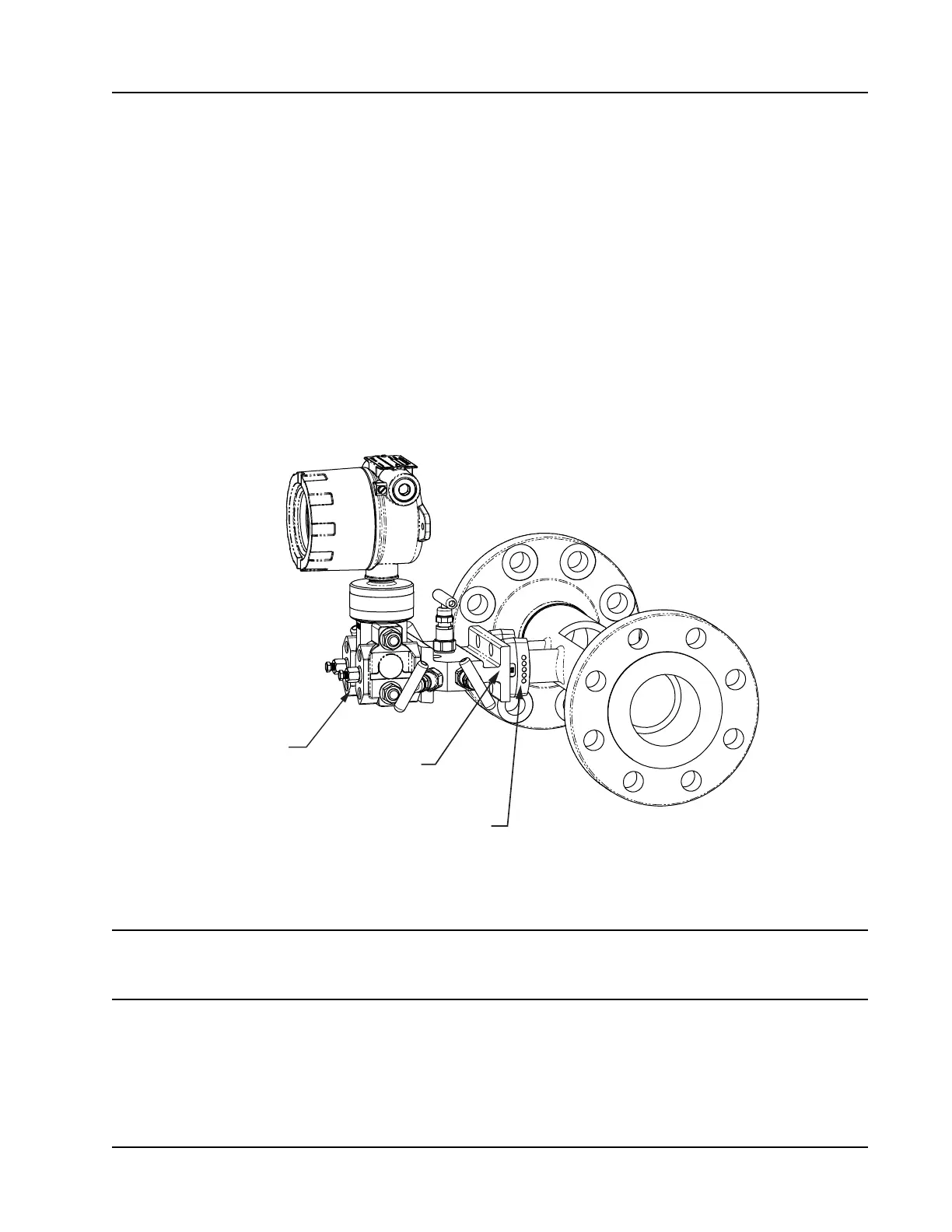

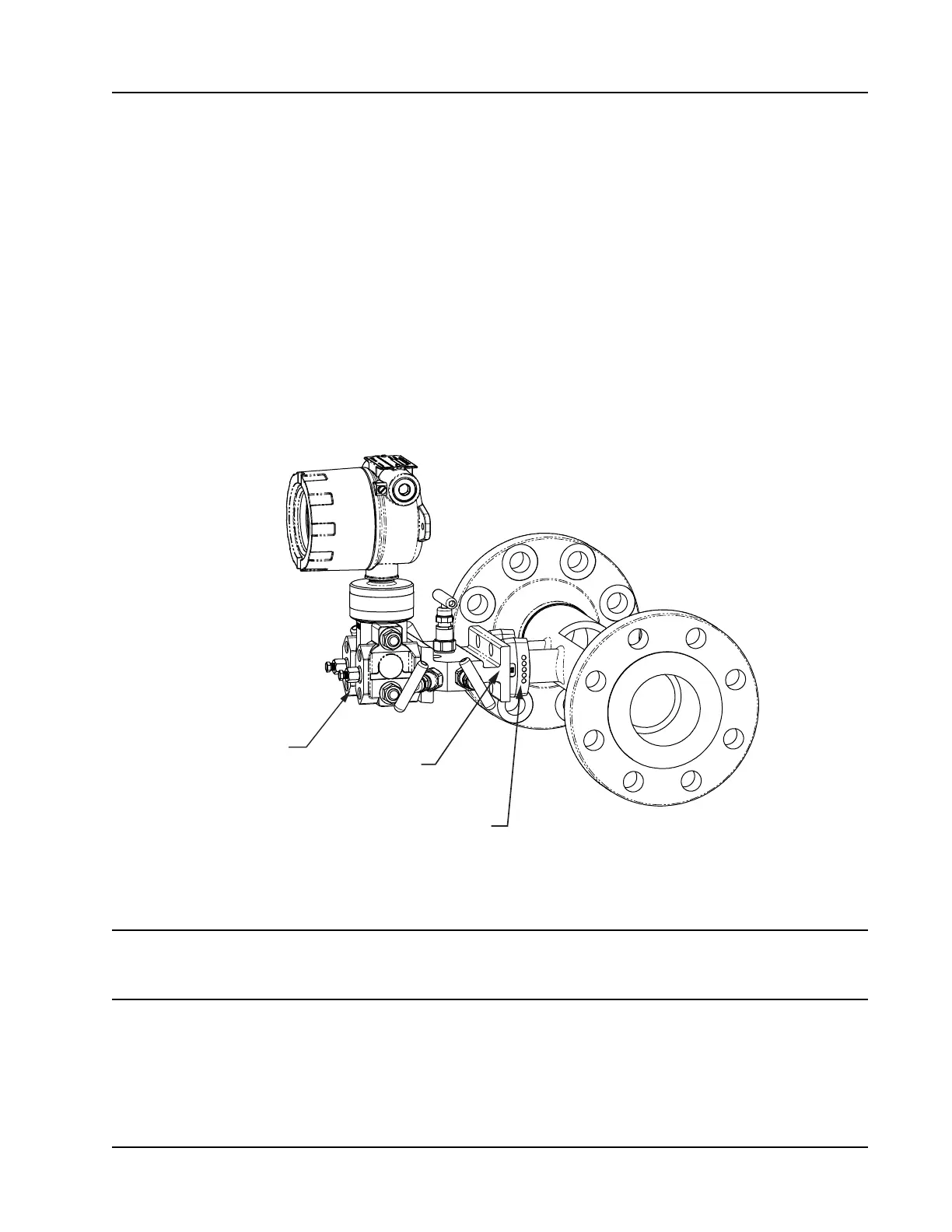

Installation Procedure—Direct Mount to Orice Meter or Cone Meter

A Scanner 2000 can be mounted directly to an orice meter or cone meter for liquid measurement using a

side-port MVT, a block manifold and two football ange adapters (Figure 2.10). The setup of the meter run

and plumbing congurations can vary widely, depending upon the challenges existing on location.

MVT with

side ports

Block

manifold

Adapter

(2 typ.)

Figure 2.10—Direct-mount liquid run installation (shown here with a cone meter). Downstream RTD is not

shown.

CAUTION When measuring liquid with a direct-mount Scanner 2000, process connections must be

parallel to the horizontal centerline of the meter, or below the centerline to eliminate air

pockets.

1. Verify that the meter is properly installed in the ow line (per manufacturer’s instructions).

2. Screw a football ange adapter onto each meter pressure tap using pipe tape or pipe dope to seal the

threads.

Loading...

Loading...