21

Scanner

®

2000 microEFM Section 1

Power Options

The standard Scanner 2000 microEFM can be powered two ways:

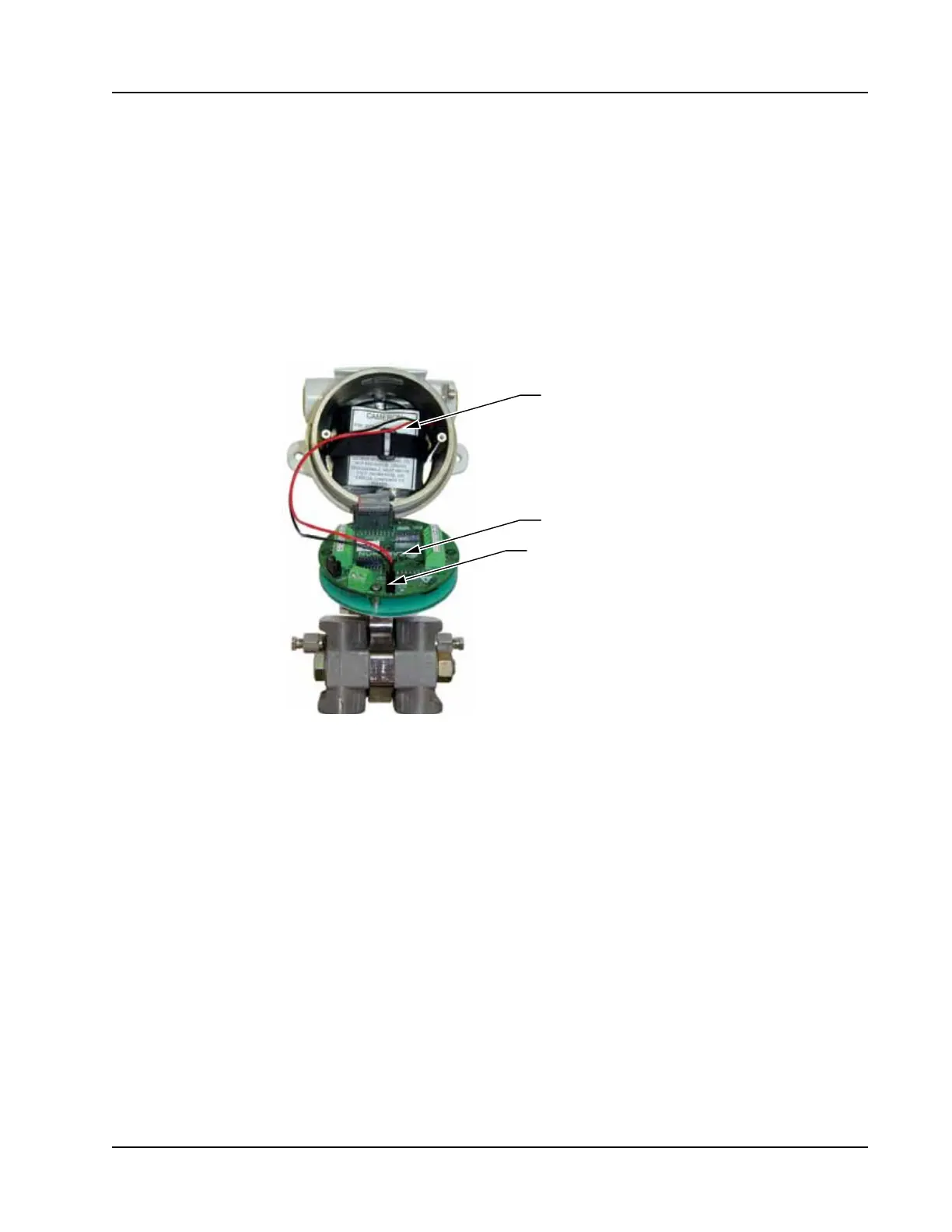

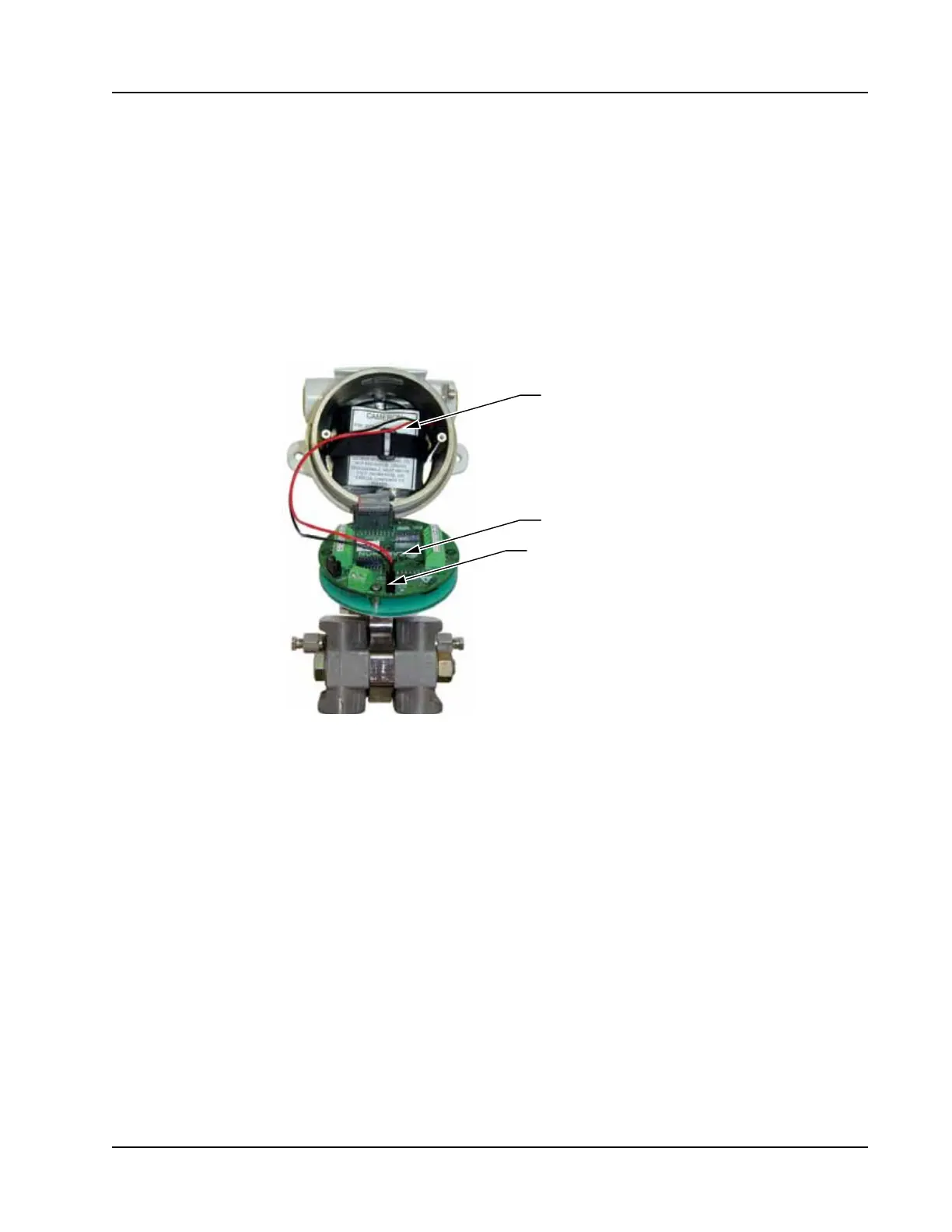

• with the internal lithium battery pack supplied with each Scanner 2000 (shown in Figure 1.5)

• with an external customer-supplied power supply (6 to 30 VDC); the lithium battery provides backup

power when an external power supply is used

Wiring diagrams are provided in Section 3—Wiring the Scanner 2000.

Foundation™ eldbus models are powered by a customer-supplied eldbus power supply. In the event that

eldbus power is lost, the lithium battery will help ensure that timekeeping and volume accumulation will not

be interrupted. See Appendix C—Scanner 2000 for Foundation™ Fieldbus for details.

Lithium battery pack

(double D cell), secured

by a velcro strap

Main circuit board

Battery connector

Figure 1.5— Scanner 2000 microEFM, internal view

Interface Software Functions

The ModWorX™ Pro interface software is designed for simplicity and ease of use. Its intuitive, well-

organized screens allow users to calibrate and congure the Scanner 2000 microEFM within just a few

minutes, and download log archives in an easy-to-read report. RTU Modbus

®

protocol and RS-485

communications ensure easy access to logs. Up to 16 user-selectable parameters can be logged and

downloaded using ModWorX™ Pro software.

The software interface is designed around the most common needs of the eld operator. A read-only Main

screen (Figure 1.6) provides a quick reference to real-time totals and ow rates, input data, and system data. It

is also home to four task-based menus: Calibrate, Maintain Flow Run, Maintain Turbine, or Congure, and a

large red “Download” button for downloading archive data.

Loading...

Loading...