27

Scanner

®

2000 microEFM Section 2

Section 2—Installing the Scanner 2000

Overview

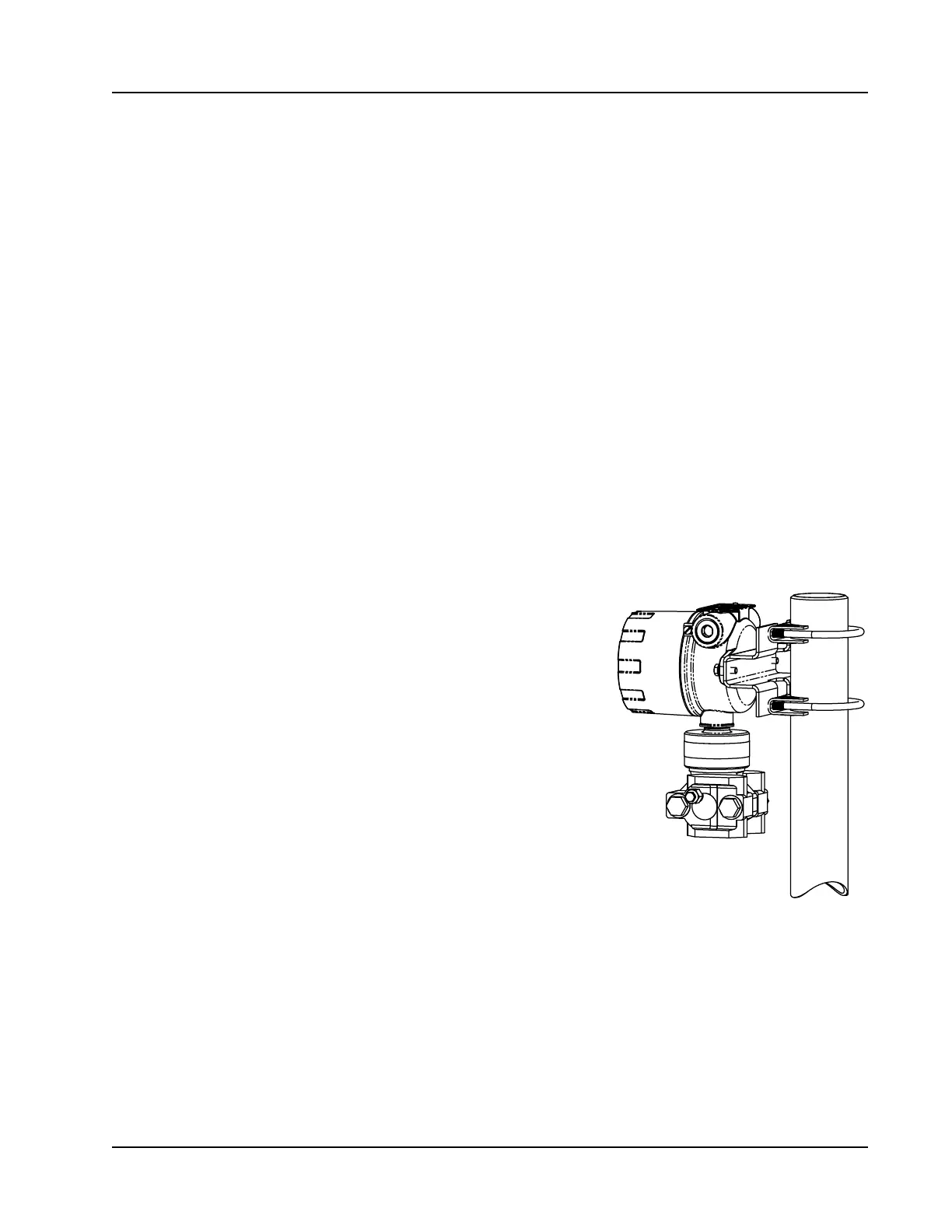

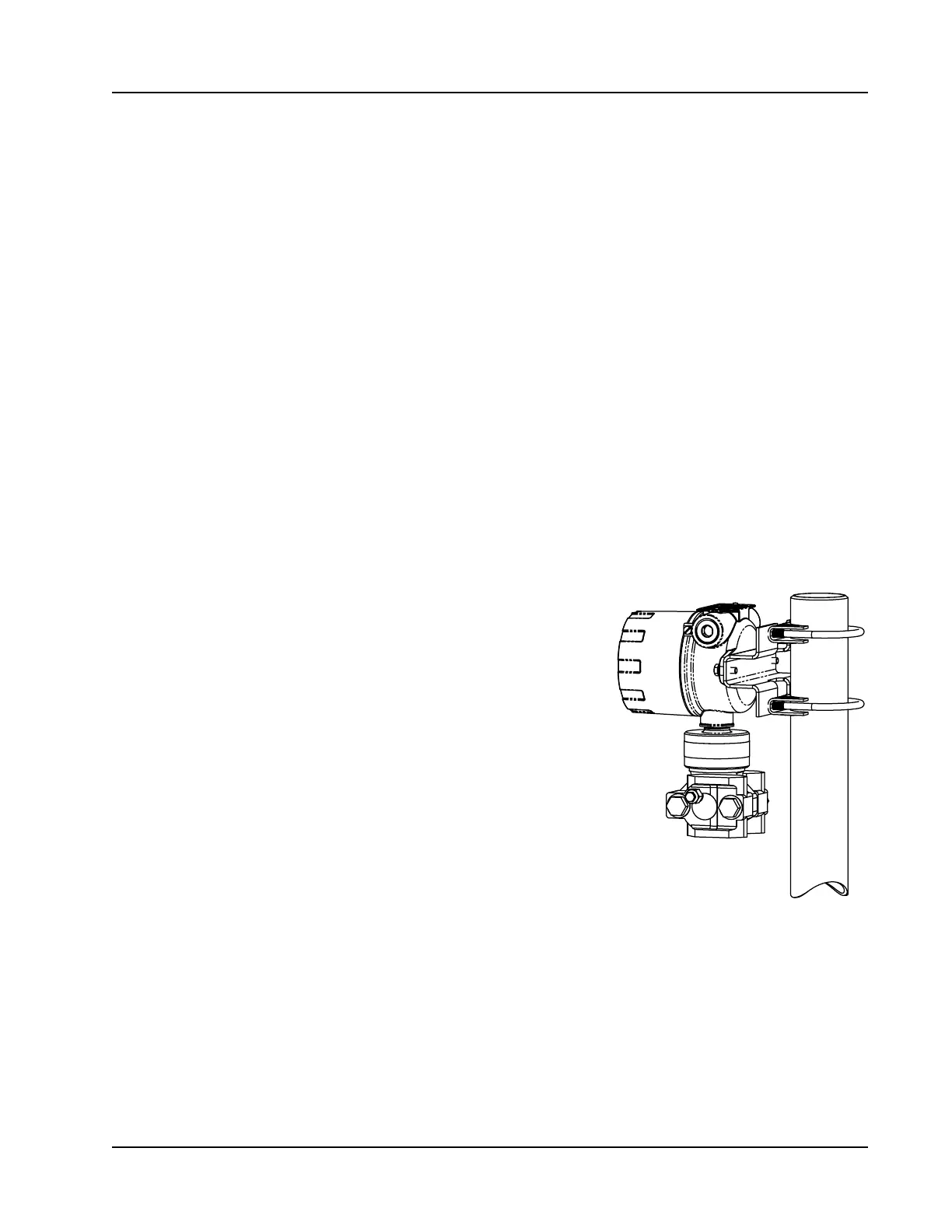

The Scanner 2000 microEFM is fully assembled at the time of shipment and ready for mounting. However,

Cameron recommends that operators congure the microEFM prior to mounting if the instrument is to be

installed in a hazardous area. The enclosure must be opened to congure the device, either via keypad controls

or via software, and once the instrument is mounted in a hazardous area, the cover should not be removed

unless the area is void of combustible gas and vapors.

Hazardous Area Installations

The Scanner 2000 is ATEX-certied (Zone 1) and CSA-certied (Div. 1 and Div. 2) for hazardous area

use. Installation requirements vary, depending on the certication required. Carefully review the following

hazardous area requirements before installing a Scanner 2000 in a hazardous area.

Zone 1 (ATEX) Installations

The ATEX-certied standard Scanner 2000 microEFM and the ATEX-certied Scanner 2000 microEFM with

expansion board are fully compliant with European ATEX Directive 94/9/EC, Annex II,1.0.6.

The following instructions apply to equipment covered by certicate number 07ATEX 1037X:

• The instrument may be located where ammable gases and va-

pours of groups IIA, lIB and IIC may be present.

• It is only certied for use in ambient temperatures in the range

-40°C to +70°C and should not be used outside this range.

• It has not been assessed as a safety-related device (as referred to

by Directive 94/9/EC Annex II, clause 1.5).

• Installation shall be carried out by suitably trained personnel in

accordance with the applicable code of practice (EN 60079-14

within Europe).

• Repair of this equipment shall be carried out by the manufacturer

or in accordance with the applicable code of practice (IEC 60079-

19).

• If the instrument is likely to come into contact with aggressive

substances, the user is responsible for taking suitable precautions

to prevent it from being adversely affected, thus ensuring that the

type of protection is not compromised.

– Aggressive substances may include, but are not limited to, acidic liquids or gases that may attack met-

als, or solvents that may affect polymeric materials.

– Suitable precautions may include, but are not limited to, regular checks as part of routine inspections

or establishing from the material’s data sheet that it is resistant to specic chemicals.

Loading...

Loading...