C-4

Appendix C Scanner

®

2000 microEFM

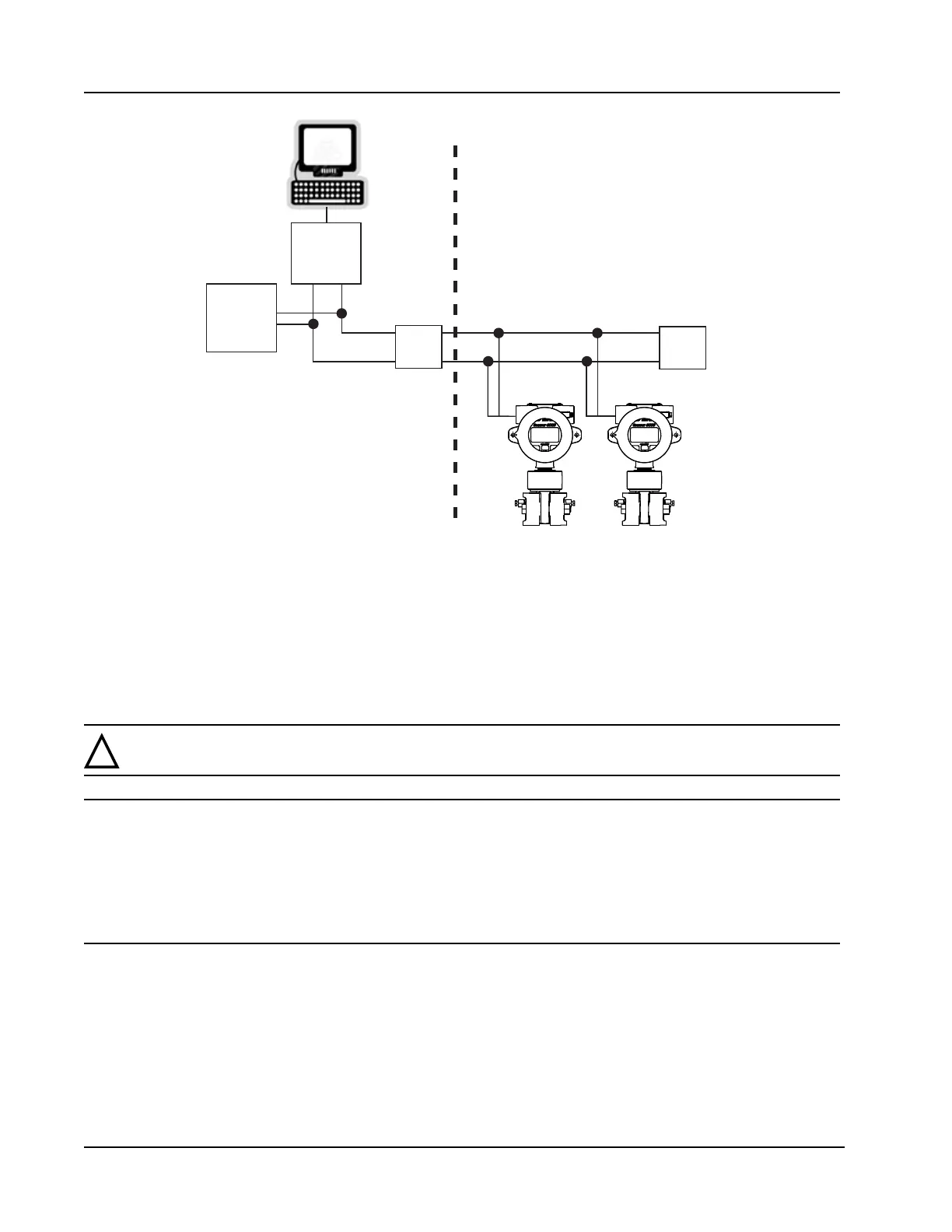

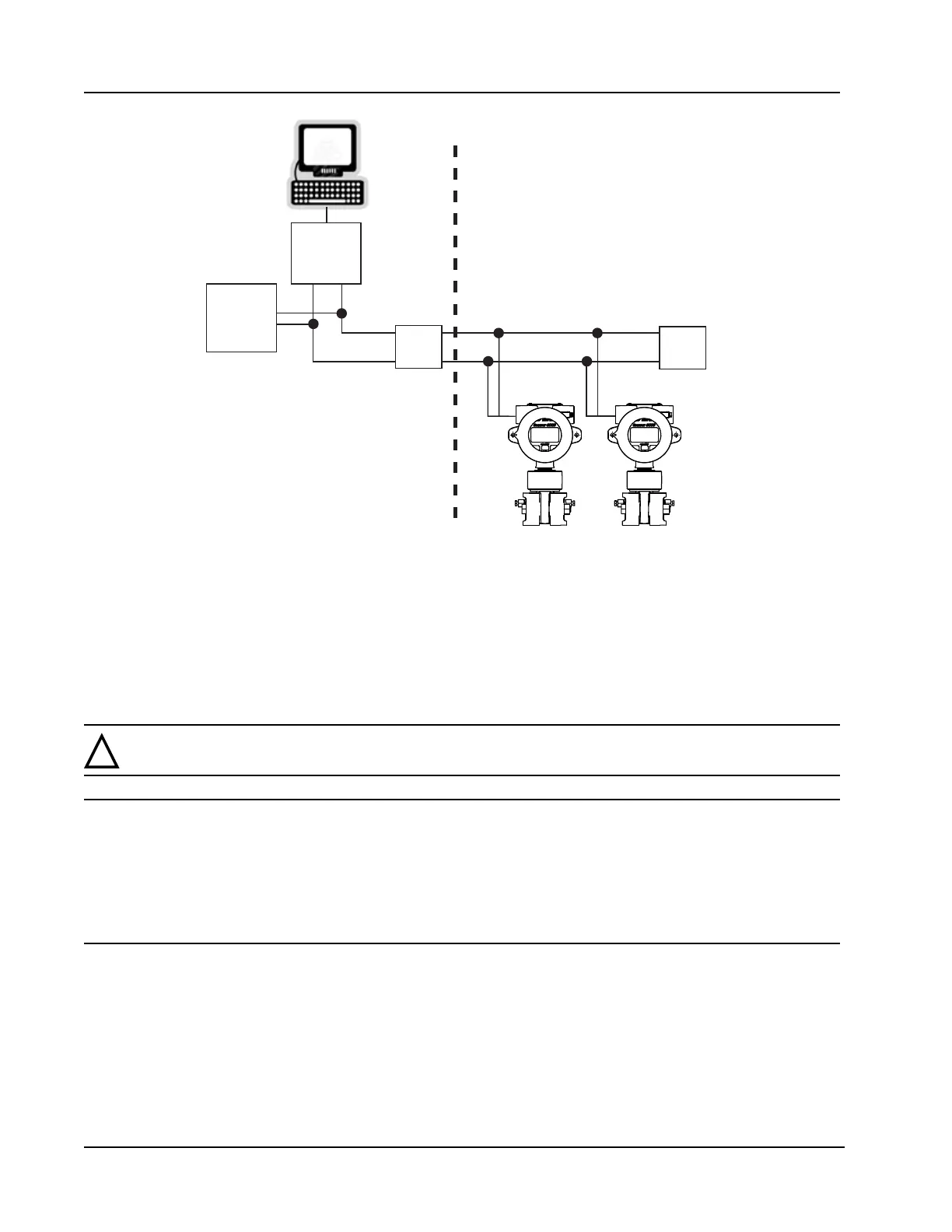

HOST

SAFE AREA

HAZARDOUS AREA

TERM

TERM

POWER

SUPPLY

LINKING

DEVICE

Figure C.2—Basic installation

Mounting Options

For instructions on mounting the Scanner 2000, see Mounting Options, page 30.

Field Wiring Connections

!

WARNING: To prevent ignition of hazardous atmospheres, do not remove the cover while cir-

cuits are alive. The Scanner 2000 poses no hazard when opened in a safe area.

CAUTION All eld wiring must conform to the National Electrical Code, NFPA 70, Article 501-4(b)

for installations within the United States or the Canadian Electric Code for installations

within Canada. Local wiring ordinances may also apply. All eld wiring must be rated for

temperatures of 90°C or higher, and have a wire range of 22 to 14 AWG. Terminal block

screws must be tightened to a minimum torque of 5 to 7 in-lbs. to secure the wiring

within the terminal block. Only personnel who are experienced with eld wiring should

perform these procedures.

The Scanner 2000 is bus-powered by a two-conductor eldbus cable that provides both power and

communications. A Scanner may be added to the network or removed from the network while the bus is

running.

Field wiring is connected to two integral circuit boards inside the Scanner 2000.

• The main board includes terminals for a communications port, a turbine input, a process temperature

(RTD) input, a digital output, and a lithium battery connector (for backup power). Use only the Model 21

explosion-proof RTD or equivalent.

Loading...

Loading...