49

Scanner

®

2000 microEFM Section 2

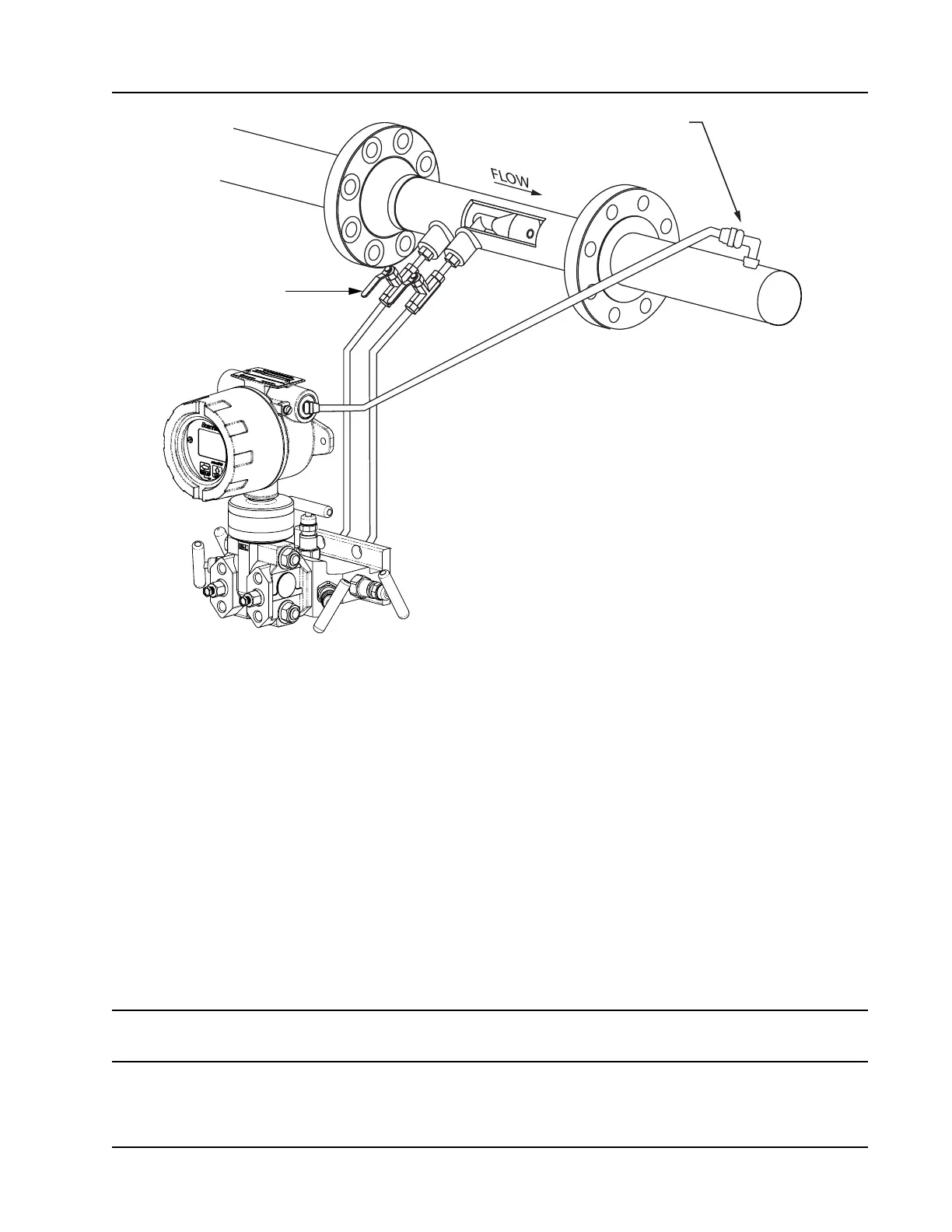

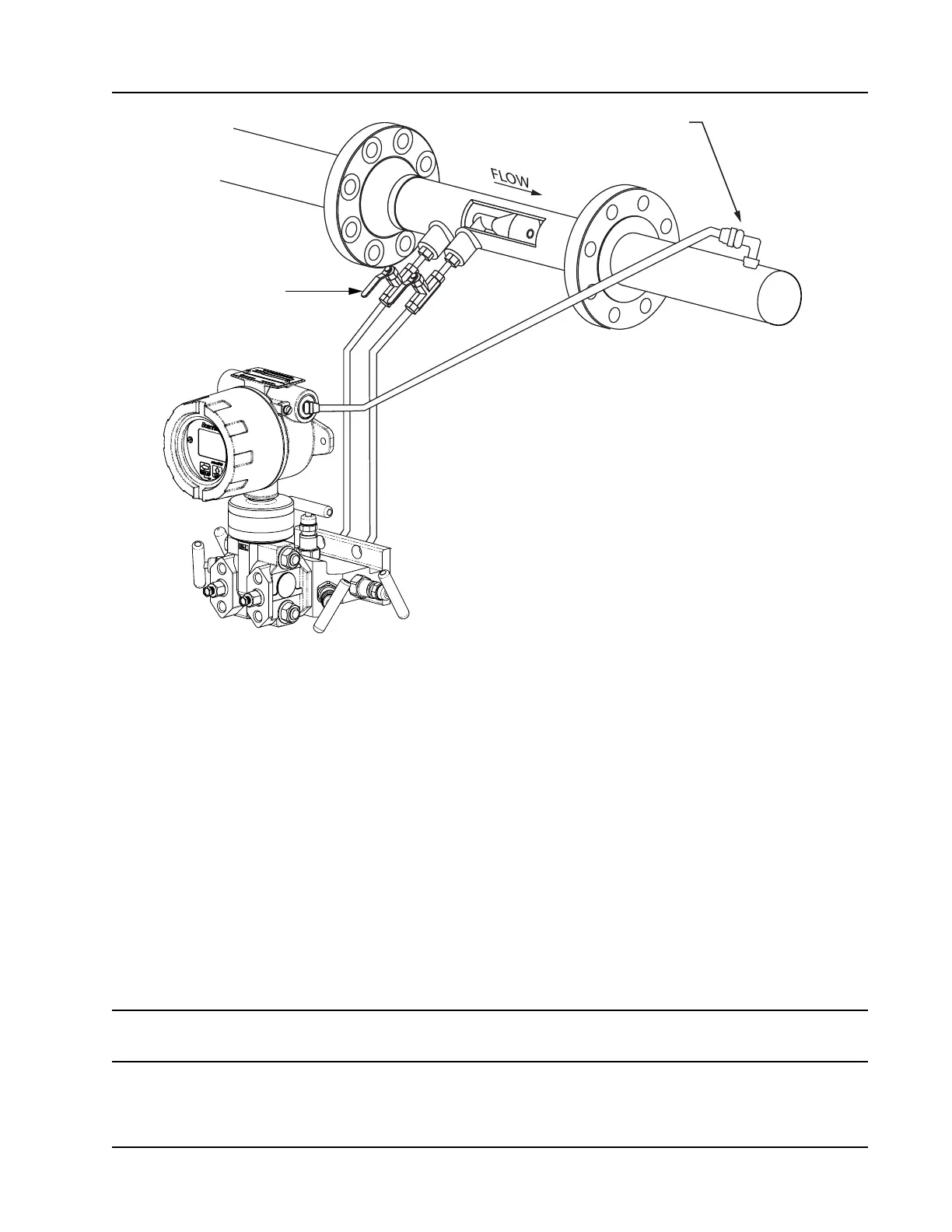

RTD assembly

Positioning of sensor below the

meter and slope of tubing helps

prevent gas bubbles from entering

the liquid

Shut-off valves

throttle flow to

the manifold

and MVT

Figure 2.11—Remote-mount liquid run installation (shown here with a cone meter). The remote-mount method

can be used with an orice meter as well.

1. Verify that the meter is properly installed in the ow line (per manufacturer’s instructions).

2. Mount the Scanner 2000 to a 2-in. pipe or to a at, vertical surface using bolts and the mounting holes in

the enclosure. A horizontal pipe is recommended, as additional hardware may be required for a vertical

pipe mount to provide clearance for the manifold block.

3. Install tubing and ttings to connect the high-pressure and low-pressure taps of the DP meter to the pro-

cess connections of the block manifold. Install a pair of shut-off valves near the high and low ports of the

DP meter. Use a suitable compound or tape on all threaded process connections.

4. Install the RTD assembly in the thermowell. Remove the plug from a conduit opening in the top of the

Scanner 2000 enclosure, route the RTD assembly cable through the conduit opening and connect it to the

main circuit board. A wiring diagram for the RTD assembly is provided in Figure 3.5, page 66. For hazard-

ous areas, review Hazardous Area Installations, page 27.

5. Route any additional inputs/outputs or COM connections, etc. through the conduit opening in the top of

the Scanner 2000. For hazardous areas, review Hazardous Area Installations, page 27.

Note To prevent ttings from turning and/or to avoid putting tension on stainless steel tubing, use a backup

wrench to attach stainless steel tubing to shut-off valves, or sensor ports.

6. To eliminate air bubbles in the MVT, manifold, and legs connecting them to the meter, ll the legs with

uid. Choose a uid that is safe for the environment, and stable when depressurized.

Loading...

Loading...