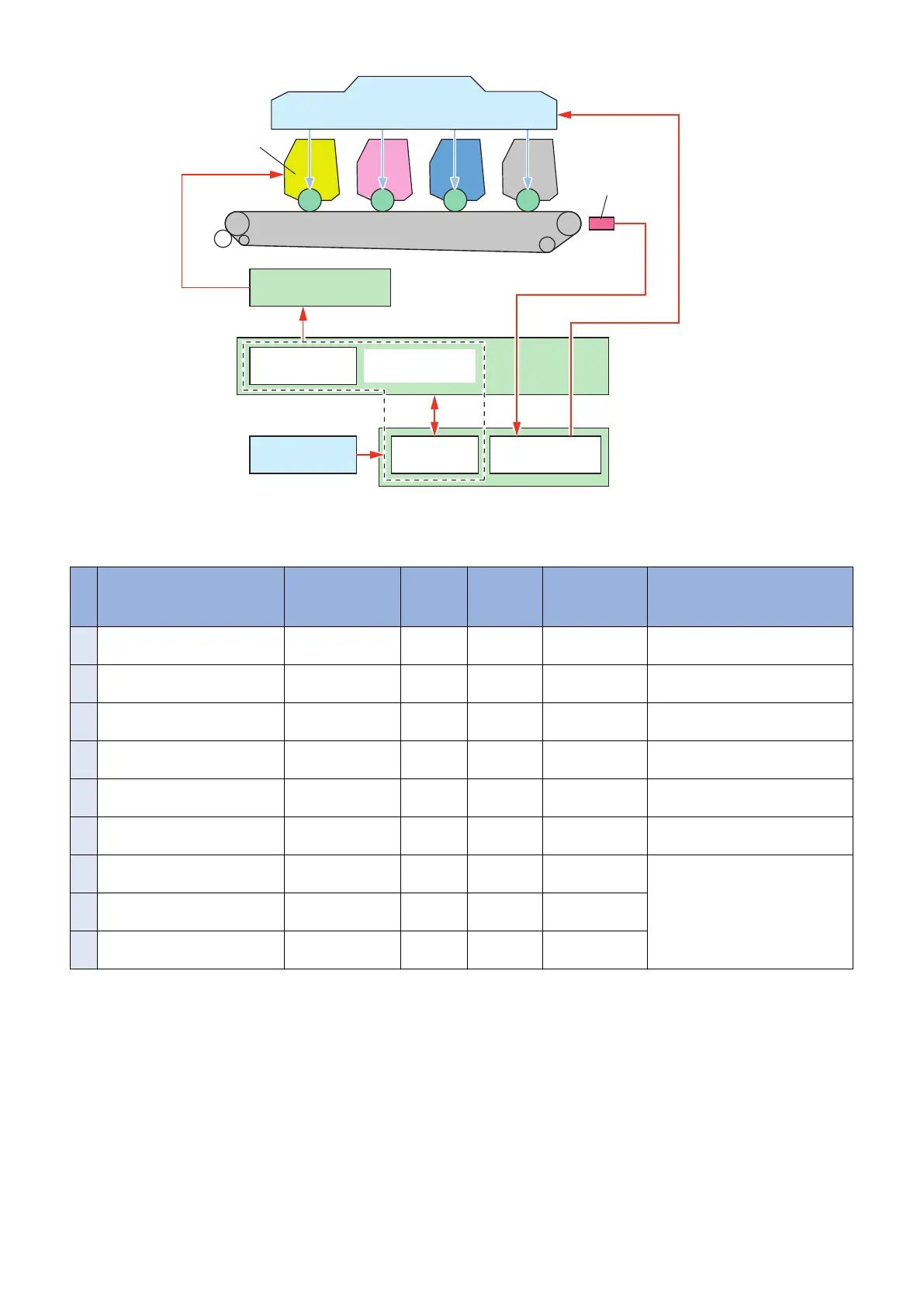

High-voltage

power supply PCBs

Reader unit

D-max

D-half

Color displacement

correction control

Toner cartridge

Laser scanner unit

ITB unit

Color

displacement/density

sensor

Signal from color

displacement/density signal

Bias

Video signal

Auto-gradation

correction control

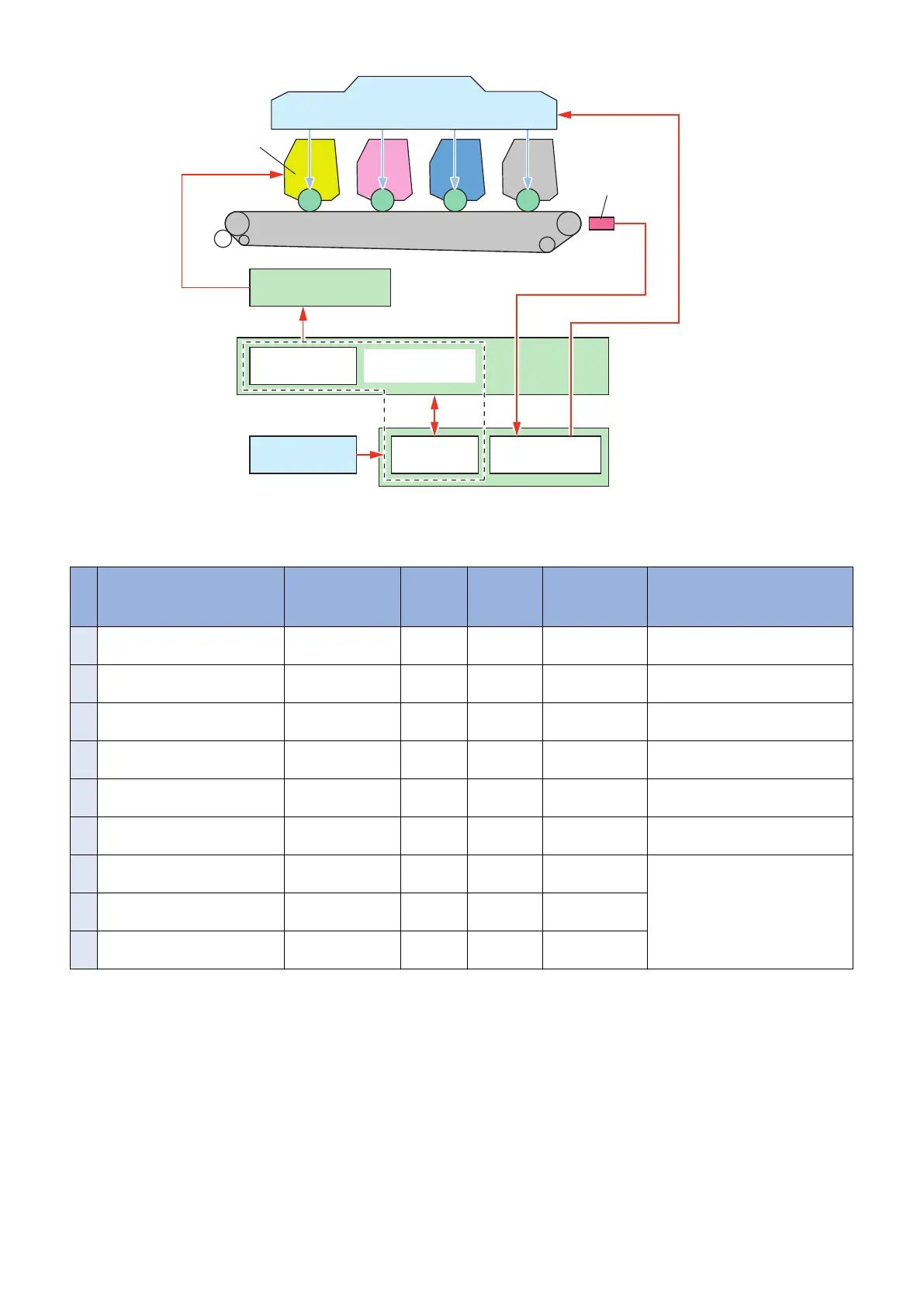

● Execution timing

The table below lists the execution timing and duration of each control.

No

.

Executiontiming Duration D-max D-half Color dis-

placement

correction

Remarks

1 Power-ON Approx.195sec-

onds

Yes Yes Yes Executed at initial rotation

2 Toner cartridge replacement Approx.195sec-

onds

Yes Yes Yes Executed at initial rotation

3 Environmentalchanges Approx.195sec-

onds

Yes Yes Yes Executed after job completionDe-

tected by the environment sensor

4 After the pre-defined counts

printed

Approx.195sec-

onds

Yes Yes Yes Executed after job completion

5 After the pre-defined time

elapsed

Approx.195sec-

onds

Yes Yes Yes Executed after job completion

6 Resumed from sleep (after 8

hours or more)

Approx.100sec-

onds

Yes Yes - Executed after job completion

upon resumed

7 Full correction Approx.100sec-

onds

Yes Yes - Executed by users

8 Quick correction Approx.100sec-

onds

Yes Yes -

9 Copy image correction Approx.100sec-

onds

Yes Yes -

● Image density correction control (D-max control)

This control is to stabilize the print image density.

The DC controller PCB triggers D-max control under the pre-defined conditions.

1. Measure the density detection patterns for each color on the ITB.

2. Technical Explanation

37

Loading...

Loading...