•

•

•

•

•

•

•

•

Troubleshooting

Remove the option board.

12.4 Total and Trip Counters

The AC drive has different counters based on the operation time of the drive and the energy consumption. Some of the counters

measure total values and some can be reset.

The energy counters measure the energy that is taken from the supply network. The other counters are used to measure, for exam-

ple, the operation time of the drive or the run-time of the motor.

It is possible to monitor all the counter values from the PC, control panel, or fieldbus. When using the PC or the control panel, it is

possible to monitor the counter values in the Diagnostics menu. When using fieldbus, it is possible to read the counter values with

the ID numbers.

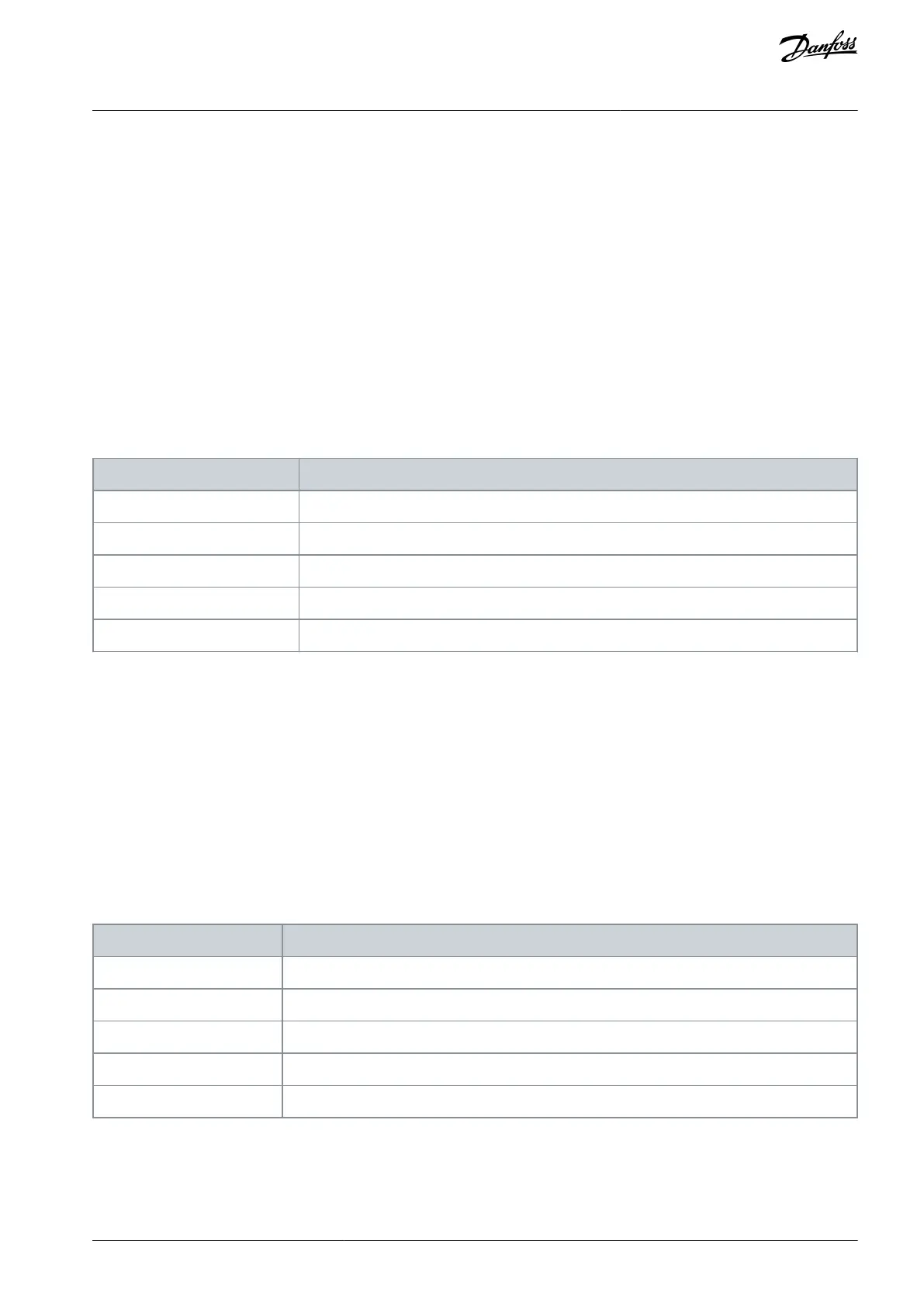

12.4.1 Operating Time Counter

Resetting: not possible

Location: submenu Total counters

The value of the counter has 5 different 16-bit values. To read the value of the counter through fieldbus, use these ID numbers.

Operating Time Counter (years)

Operating Time Counter (days)

Operating Time Counter (hours)

Operating Time Counter (minutes)

Operating Time Counter (seconds)

Example

The value 1a 143d 02:21 is received from the operating time counter from the fieldbus.

ID1754: 1 (years)

ID1755: 143 (days)

ID1756: 2 (hours)

ID1757: 21 (minutes)

ID1758: 0 (seconds)

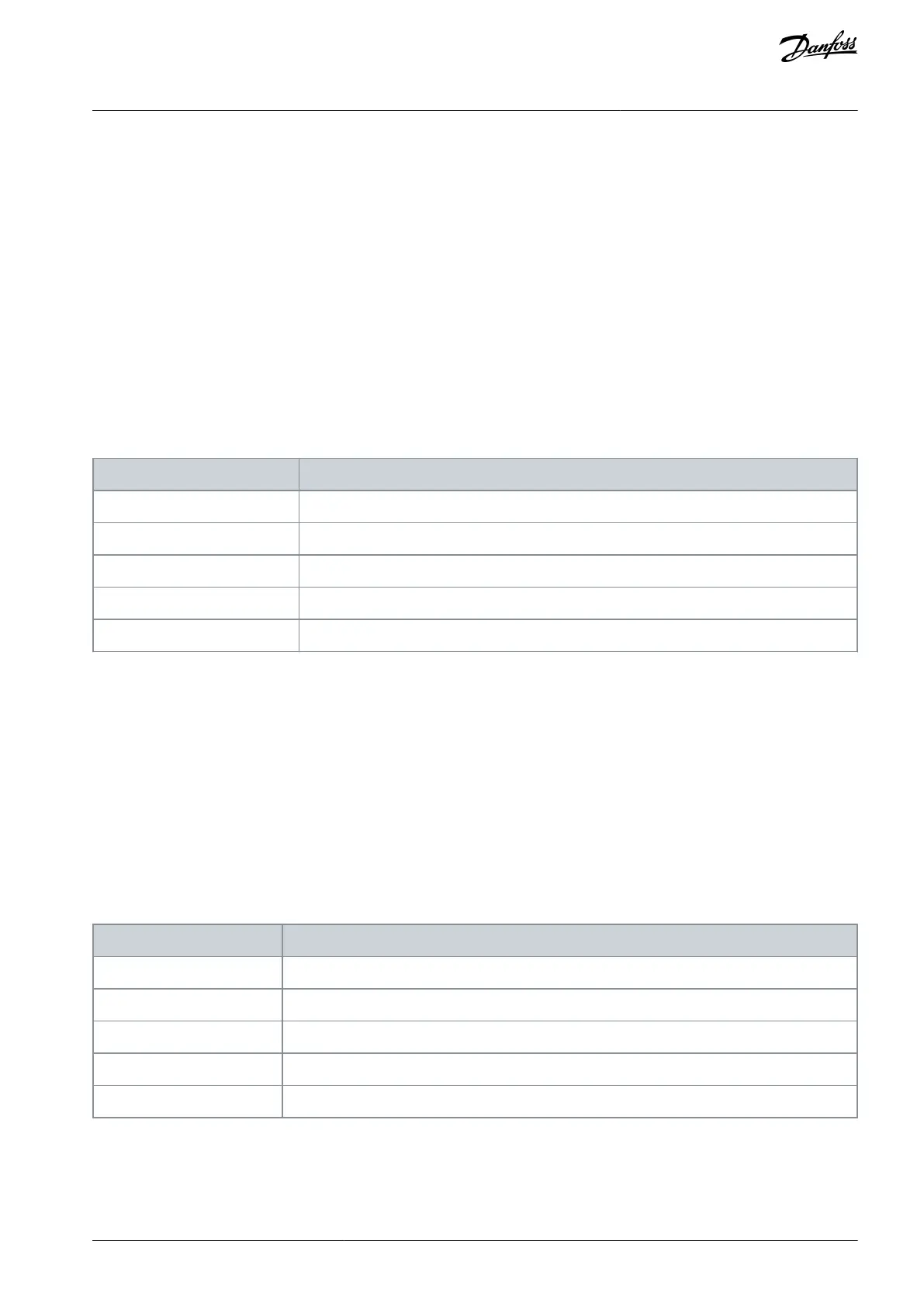

12.4.2 Operating Time Trip Counter

The operating time trip counter of the control unit can be reset. It is in the submenu Trip counters. It is possible to reset the counter

with the PC, the control panel, or the fieldbus. The value of the counter has 5 different 16-bit values. To read the value of the coun-

ter through fieldbus, use these ID numbers.

Operating Time Trip Counter (years)

Operating Time Trip Counter (days)

Operating Time Trip Counter (hours)

Operating Time Trip Counter (minutes)

Operating Time Trip Counter (seconds)

Example

The value 1a 143d 02:21 is received from the operating time trip counter from the fieldbus.

ID1766: 1 (years)

ID1767: 143 (days)

AB298035655957en-000201 / DPD01083 | 321Danfoss A/S © 2023.08

Fault Tracing

VACON® 100 FLOW

Application Guide

Loading...

Loading...