10. Navigation

◦ Stop the cycle

◦ Back to the main edging screen

◦ Start the edging cycle

c. Customised grooving

The use of the customized groove depends on two parameters: the frame and the lens. Before starting your

job, identify the major constraint.

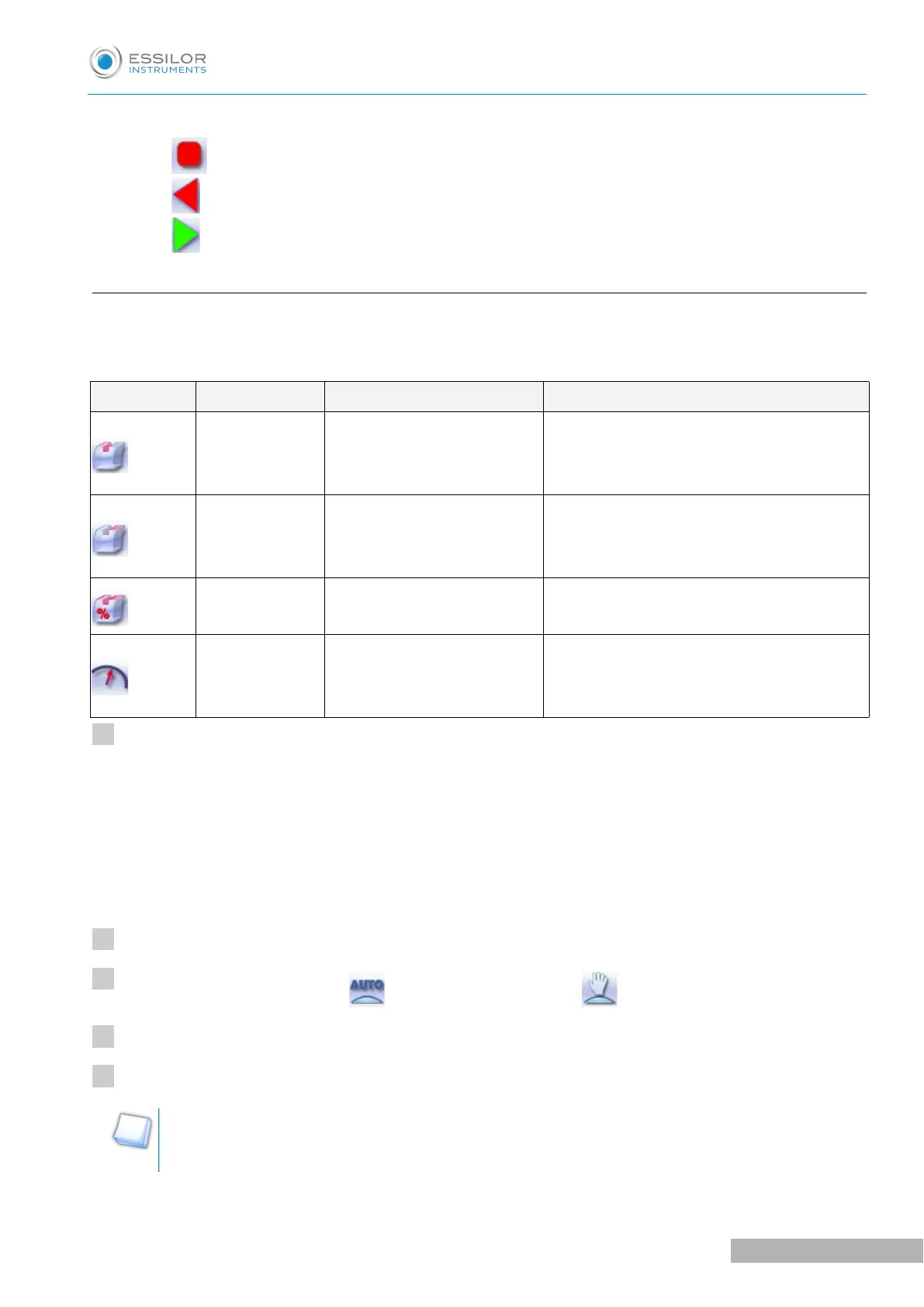

GROOVE FRAME LENS ADVANTAGES

Standard groove

Lens for which the front

surface base is approximately

equal to the frame base.

Makes it possible to do an aesthetically

pleasing job. The lens material does not

protrude beyond the front of the frame.

Standard groove

Lens for which the rear

surface base is not as high as

the front surface base.

Minimises the risks of the nylon thread

coming out.

Standard groove Thin lens

Makes it possible to balance out the groove

when thin lenses are used.

Flat base

Cambered base

Thin lens for which the front

surface base is approximately

equal to the frame base.

In the event of pattern tracing (base = 0),

makes it possible to retrieve the frame base.

Call up the desired shape located on the tracer.

The shape is displayed on the edger work screen.

After tracing a pattern, demo lens or recut lens, without any drilling settings:

• the groove finish is selected by default.

• The automatic mode is selected by default.

Select lens material.

Change the edging mode. Press to select customized mode .

Select the type of cycle.

Choose whether or not to polish and/or chamfer your lens.

For more information, consult the section Edging a lens > Perform a polishing (F p.121) and Edging

a lens > Perform a chamfering (F p.121).

Loading...

Loading...