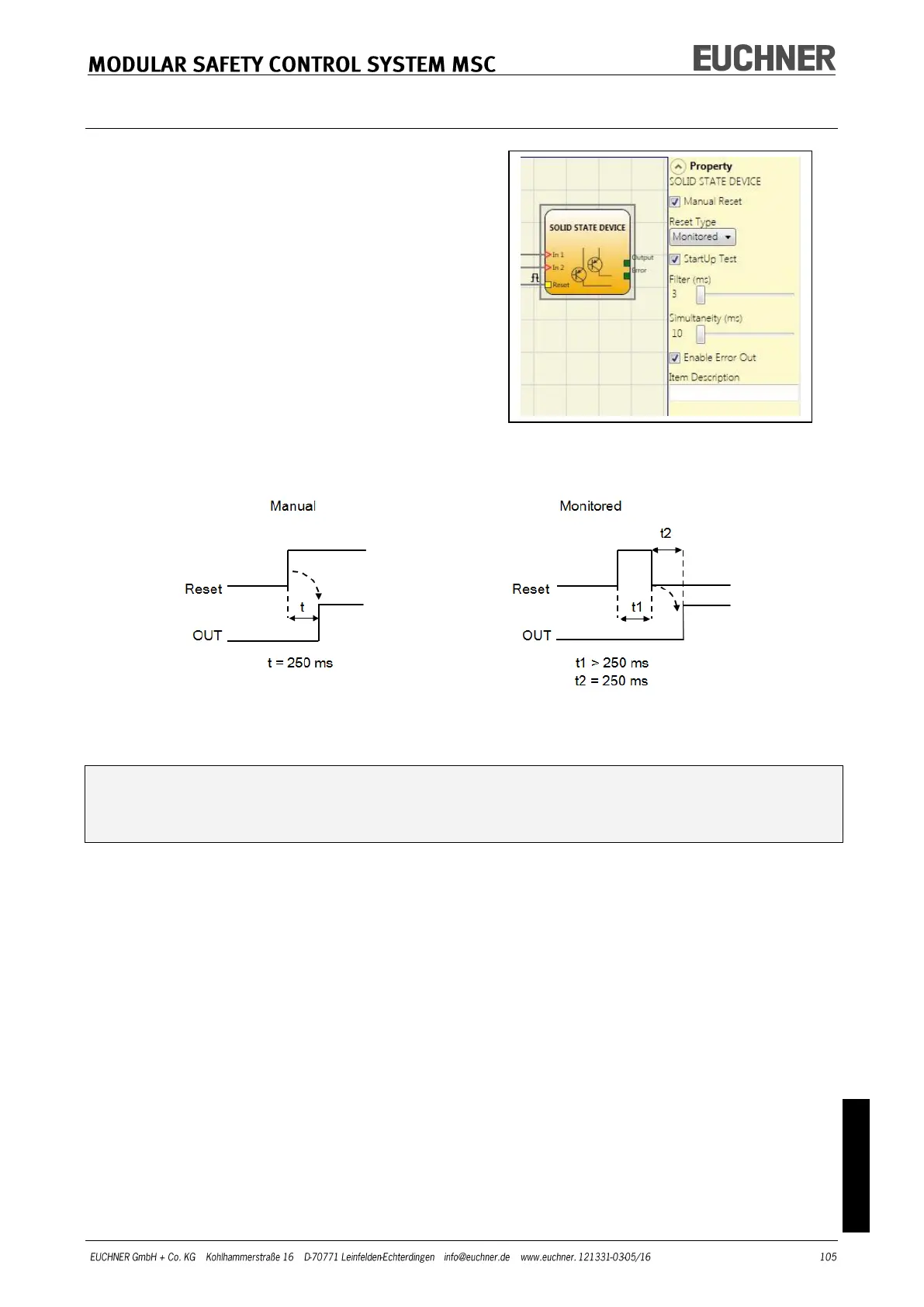

SOLID STATE DEVICE

Using the SOLID STATE DEVICE function block

the status of the inputs is checked. If 24 VDC

are present on the inputs, the OUTPUT output

switches to "1" (TRUE), otherwise the OUTPUT

output is "0" (FALSE).

Parameters

Manual Reset: If selected, a reset can be re-

quested on every activation of the safety func-

tion. Otherwise the activation of the output will

correspond directly to the input conditions.

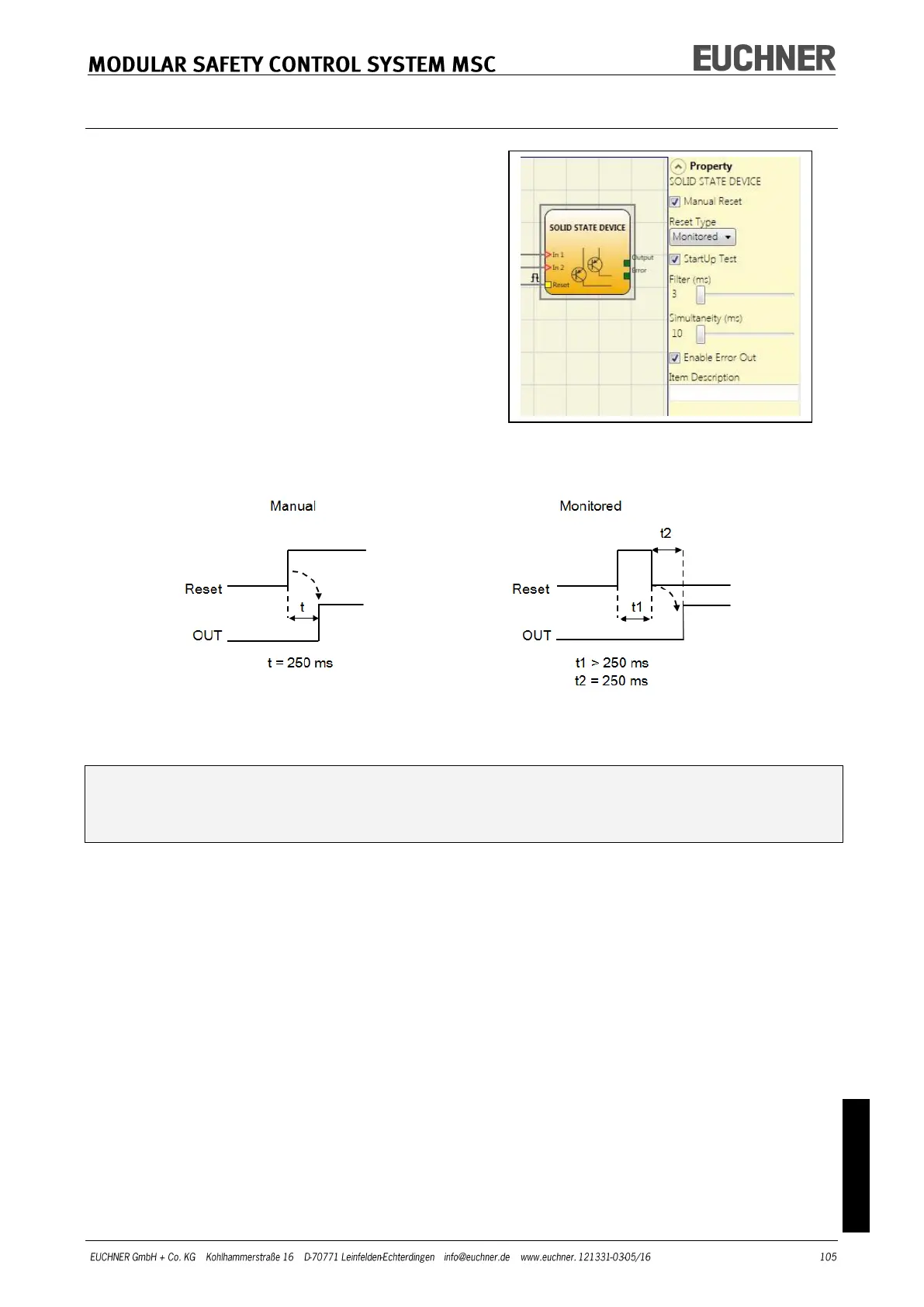

There are two types of reset: "Manual" and "Mon-

itored". On the selection of the manual reset, the

system only checks the signal transition from 0 to 1. With the monitored reset the double

transition from 0 to 1 and then back to 0 is checked.

WARNING: If reset is activated, the input after the inputs used by the function block

must be used. Example: If Input1 and Input2 are used for the function block, Input3

must be used for the reset.

StartUp Test: If selected, the test is undertaken on switching on the safety device. This

test requires the activation and deactivation of the device to carry out one complete func-

tion test and to activate the output. This test is only requested on starting the machine

(switching on the module).

Filter (ms): This parameter makes it possible to filter the signals from the safety device.

The filter can be set to between 3 and 250 ms and removes any contact bounce. The time

set for the filter affects the calculation of the total response time of the module.

Simultaneity (ms): Defines the maximum permissible time (ms) between the switching of

the two different signals that are received from the device.

Enable Error Out: If selected, an error detected by the function block is signaled.

Item Description: Makes it possible to add a functional description of the component.

This text is displayed in the upper part of the symbol.

Loading...

Loading...