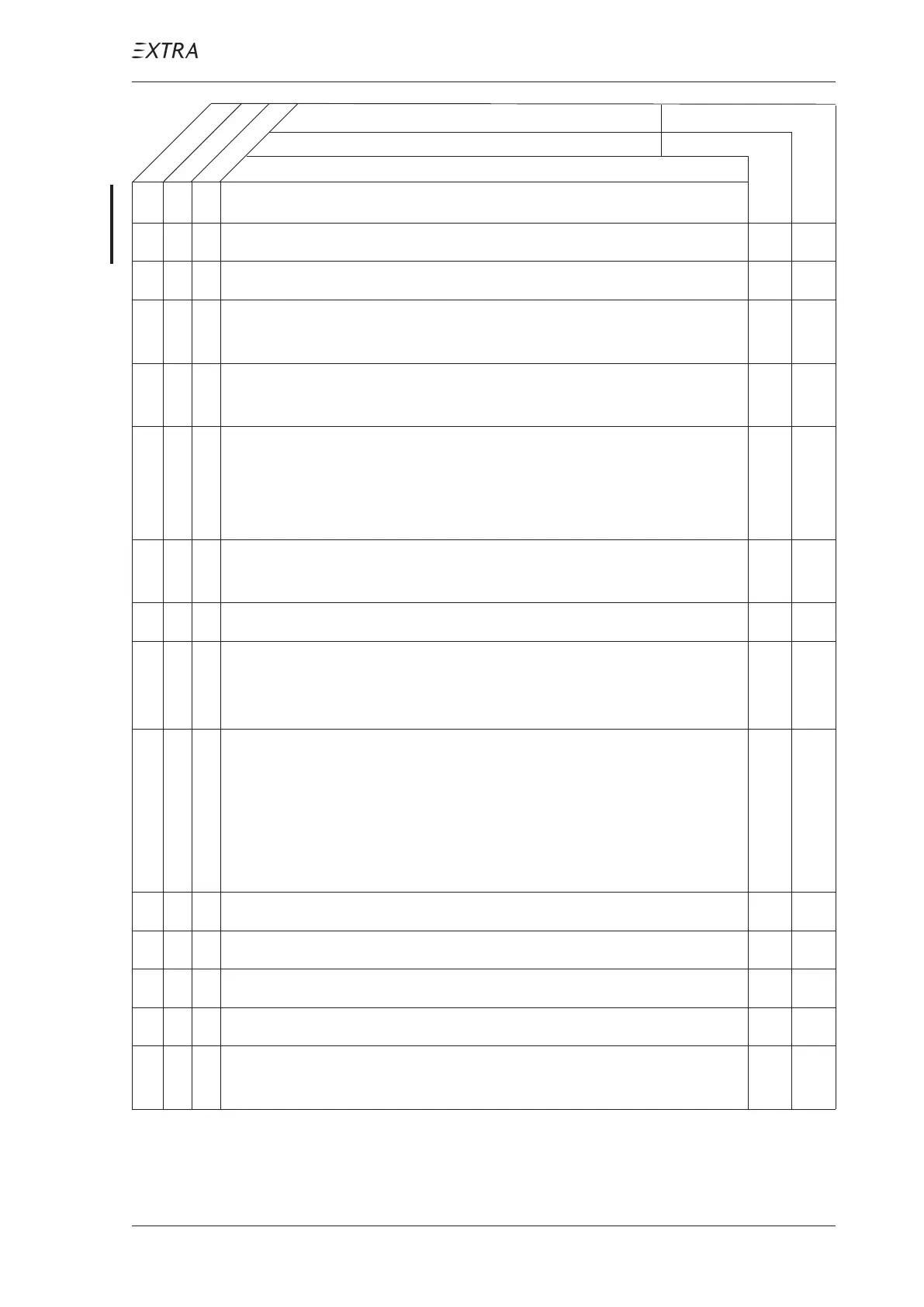

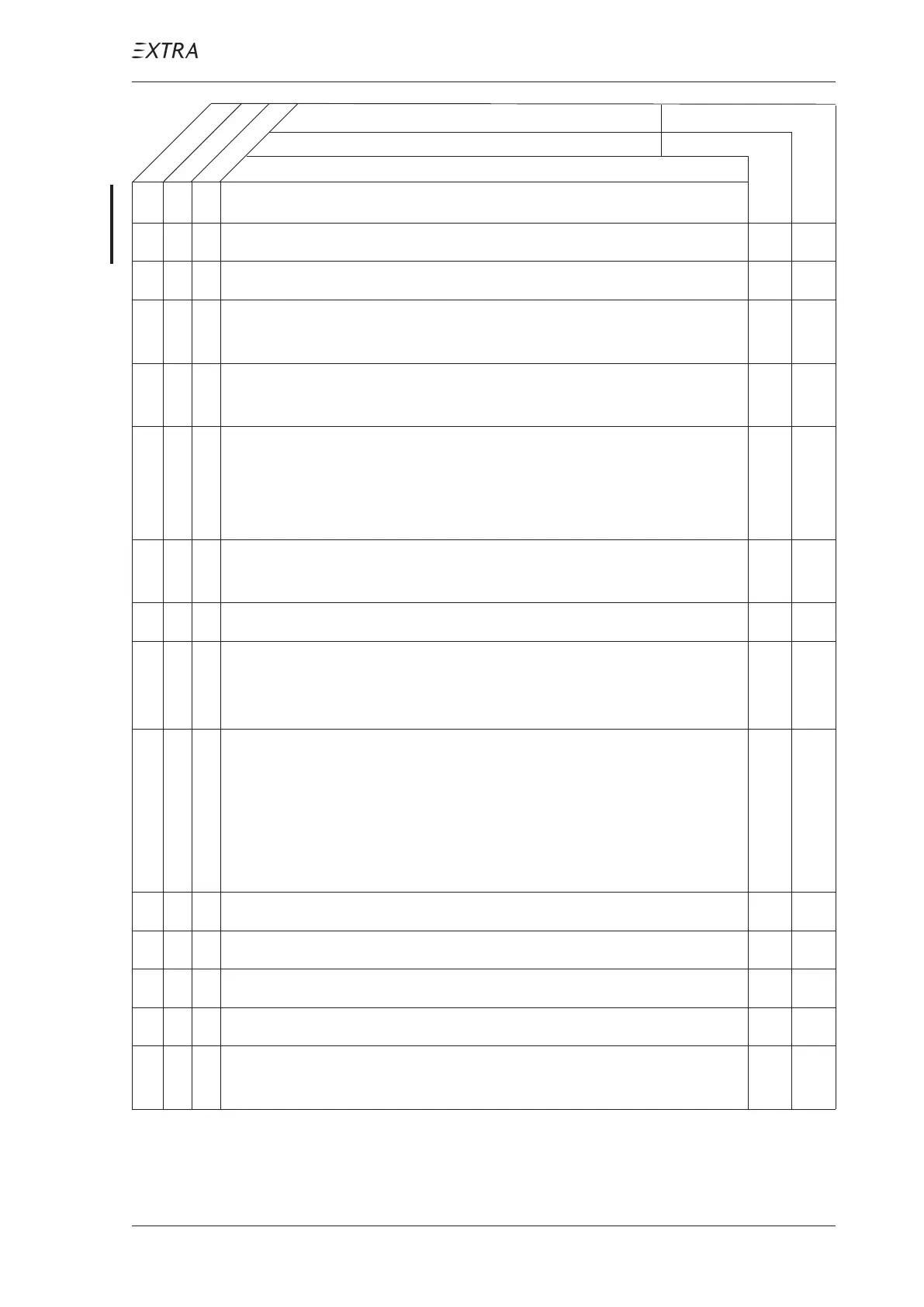

CHAPTER 5

PAGE 18

PAGE DATE: 14. August 2015

MAINTENANCE MANUAL EXTRA 330LX

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 50 hours

each 100 hours

O

1

56 Overhaul or replace propeller governor as required.

O

2

57 Complete overhaul of engine or replace with factory rebuilt

Fuselage

O O 1 Remove tail fairing, tail side skins, main fuselage cover and

landing gear cuffs per chapters 51 and 53.

O 2 Remove bottom fuselage cover including exhaust area

covering sheet per chapter 53.

O O 3 Inspect main and bottom fuselage cover including exhaust

area covering sheet, tail fairing, tail side skins and landing

gear cuffs for general condition, dents, cracks and loose

screws.

O O 4 Check installed parts for general condition and security of

attachment.

O O 5 Inspect fuselage for foreign objects.

O 6 Inspect steel tube construction for general condition, cor-

rosion and cracks, above all in areas of load stress (e.g.

wing, stabilizer, engine and seat attachments).

O O 7 Visually inspect steel tube construction in the area of hori-

zontal stabilizer attach brackets for cracks. In case of doubt

remove horizontal stabilizer and use a dye check penetrant.

In case cracks are found contact EXTRA-

Flugzeugproduktions- und Vertriebs- GmbH for repair

advice.

O O 8 Inspect fabric cover for general condition.

O 9 Inspect wooden longerons for damage.

O 10 Clean and lubricate canopy hinges and latching mechanism.

O 11 Inspect breather line for obstructions and security.

O 12 Inspect main and auxiliary wing spar connector for general

condition.

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

1 refer to Woodward Service Bulletin No. 33580 or applicable MT-Propeller Instructions

2 refer to Lycoming Service Instruction No. 1009

Loading...

Loading...