Chapter 8 System Operation

PAGE 8- 32

8-7-2 System Parameters

D-No.000

Torque Unit

All fastening parameters within the Controller will have the same torque unit.

Unit

N

・

m

kgm kgcm Ftlbs Inlbs

D-No.001

Firmware Version

Version of the controller Firmware

D-No.002

Amplifier Version

Version of servo amplifier Firmware

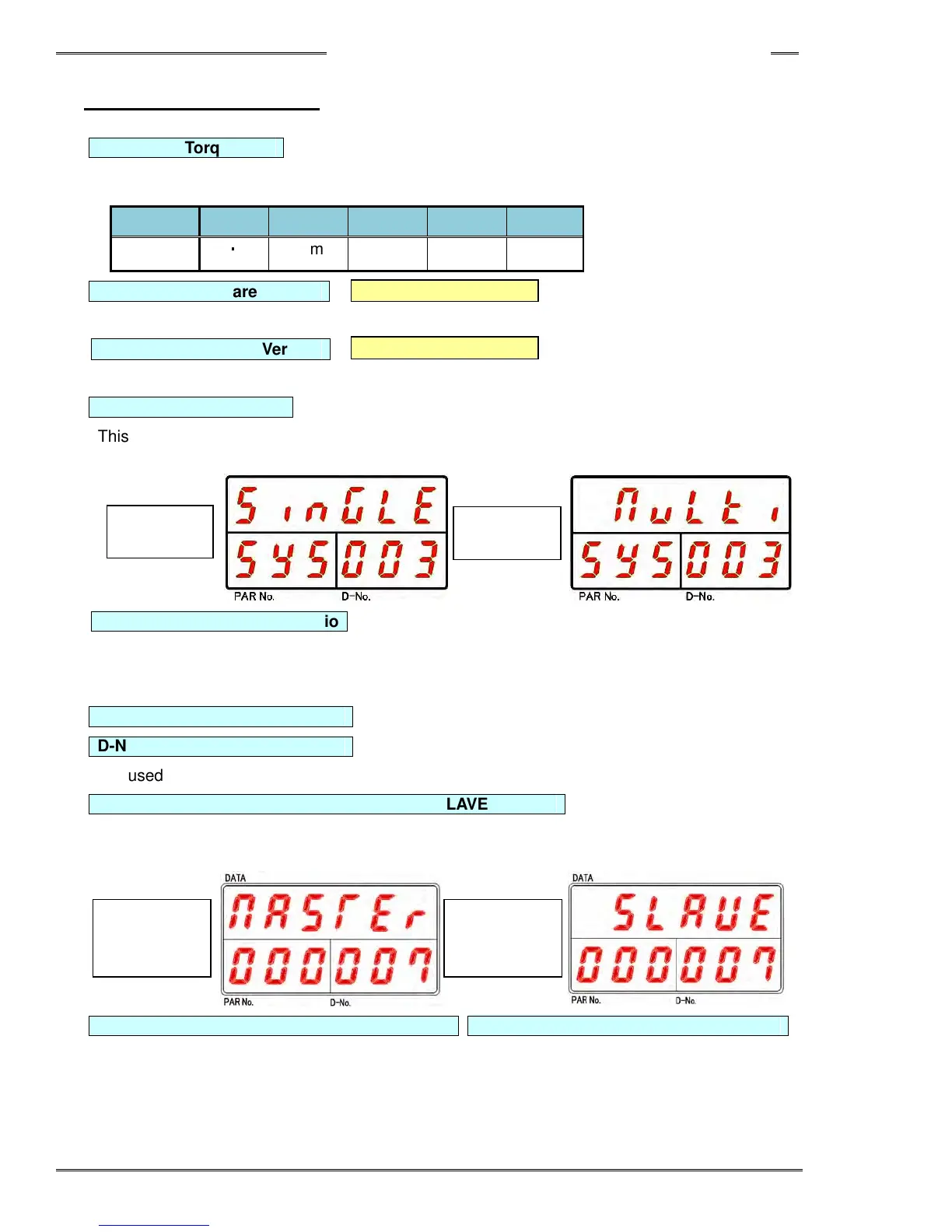

D-No.003

System Type

This is used for switching between the multi system and single system.

Refer to Section 8-5 “System Change-Over” for more details.

D-No.004

External Gear Ratio Standard setting: 1.000, Setting range: 0.300 to 3.000

Used to adjust the gear ratio when an external head (that has a gear ratio other than 1:1) is connected to

the output shaft of the tool. Do not use a value other than the standard setting (1.000) unless an external

offset gear is attached.

D-No.005

In-house adjustment

D-No.006

In-house adjustment

Not used.

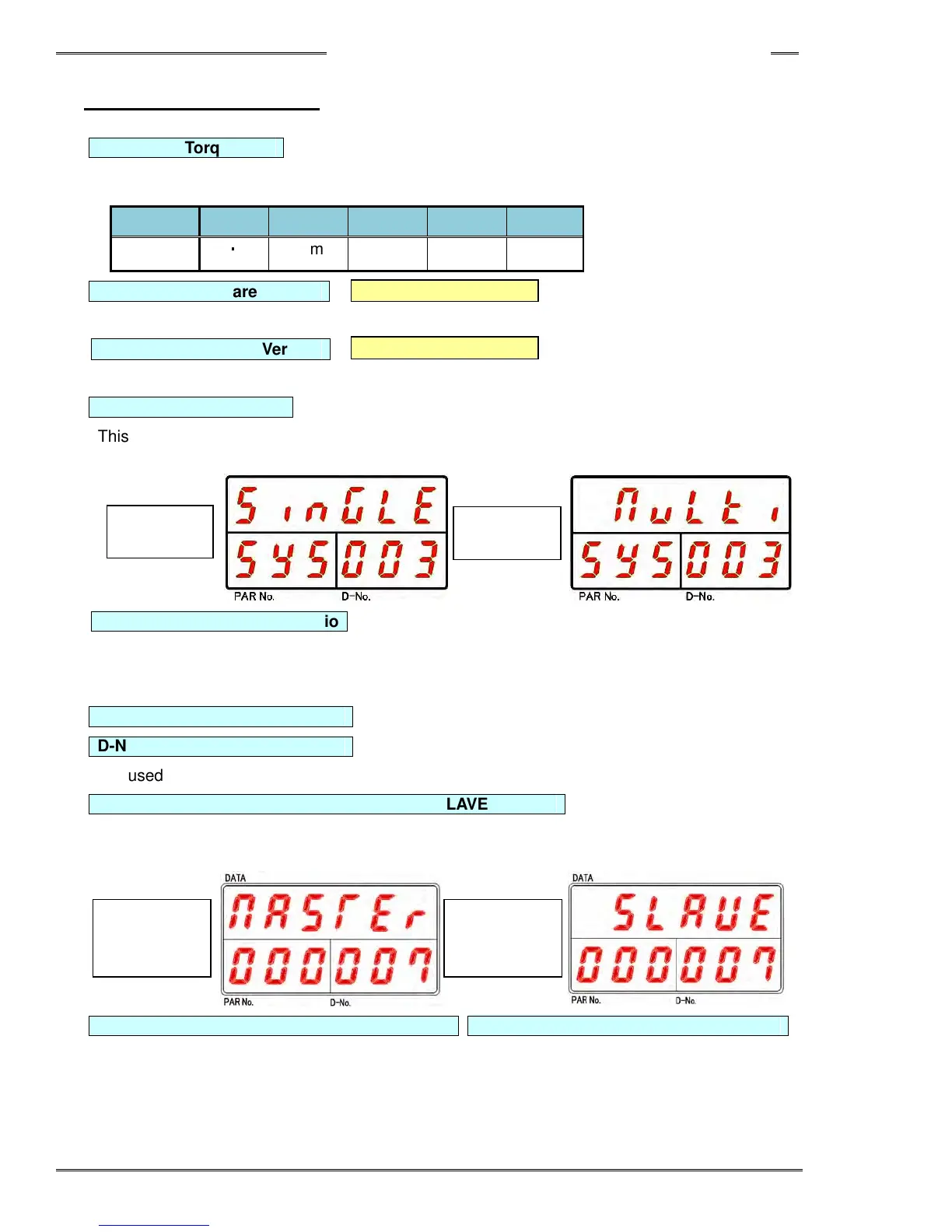

D-No.007

Axis Communication (MASTER, SLAVE) Display

This indicates whether the controller is the MASTER (for (PC) communication and I/O (PLC)

communication) or SLAVE spindle.

D-No. 008 Controller Cycle Count (×1 million) D-No. 009 Controller Cycle Count (×1)

Indicates the number of fastening cycles the controller has performed.

* When the count is less than 1 million, [------] is indicated for D-No. 008.

MASTER

(Master

Spindle)

SLAVE

(Slave

Spindle)

Single

System

Multi

System

Loading...

Loading...