Chapter 8 System Operation

PAGE 8- 35

[System Parameters – continued]

D-No. 200 Controller Setup Tool No.

Setting range: Tool No. registered for the model

The Tool No. of the connected tool is set with reference to “Tool Models” on Section 2-2-3. When the

controller tool No. is changed, initialization and automatic correction of the fastening parameter set

values are performed.

D-No. 201 Controller Setting Tool Information

The tool and motor model number setup in the parameter (at D-No. 200) are indicated.

(ex. “101rs1”)

D-No. 202 Parameter Setting File Version

The version of the parameter file set in the controller is indicated.

D-No. 203 Sequence Setting File Version

The version of the sequence file set in the controller is indicated.

D-No. 204 PLC Output Layout Setting File Version

The version of the PLC output layout file set in the controller is indicated.

D-No. 205 Fieldbus Setting File Version

The version of the fieldbus file set in the controller is indicated.

D-No. 206 Fieldbus Message Setting File Version

The version of the fieldbus message file set in the controller is indicated.

D-No. 207 RS232C Input/Output Setting File Version

The version of the RS232C input/output set in the Controller is indicated.

D-No. 208 Controller RS232C Communication Speed [bps]

The communication speed of the RS232C interface on the controller front panel is indicated.

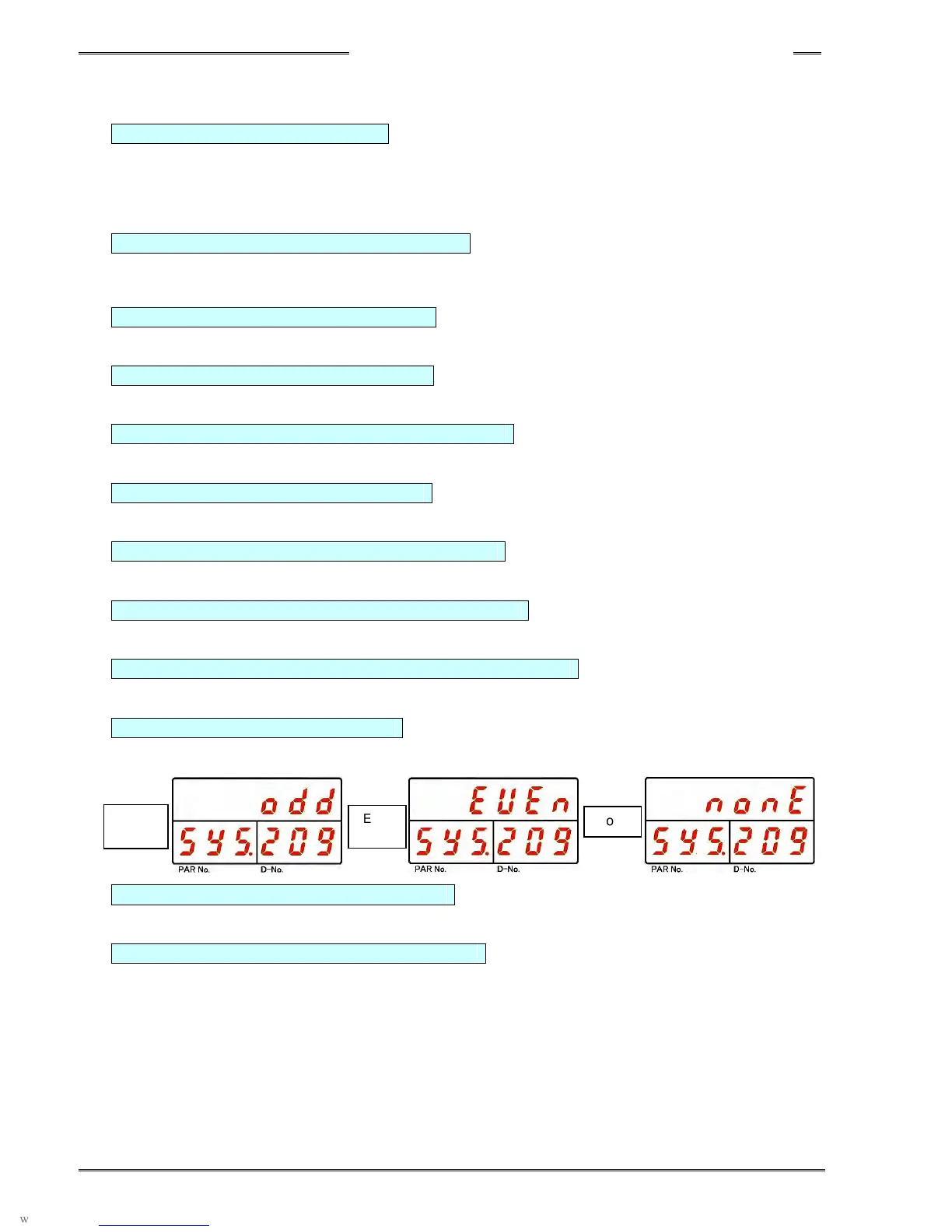

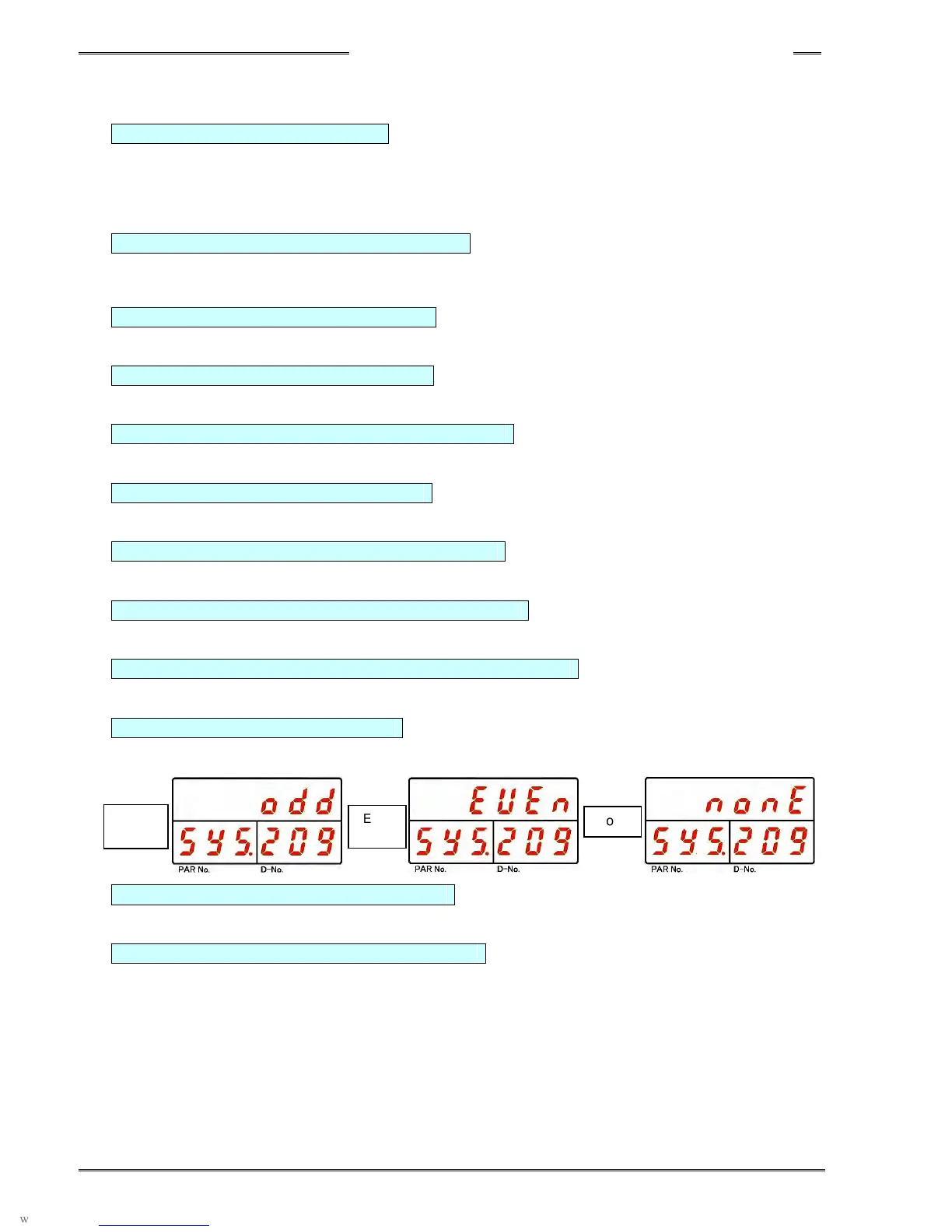

D-No. 209 Controller RS232C Parity

The parity of the RS232C interface on the controller front panel is indicated.

D-No. 210 Controller RS232C Stop Bit [bit]

The stop bit of the RS232C interface on the controller front panel is indicated.

D-No. 211 Controller RS232C Data Length [bit]

The data length of the RS232C interface on the controller front panel is indicated.

Odd

Even

None

Loading...

Loading...