UMG70XV3-4EN 12.01.2009 31

5 Selection of the Measuring Point

The following conditions have to be observed at the measuring point:

• no material deposits in the pipe

• no accumulation of liquid (condensate), e.g. before orifice plates or at pipe sections lo-

cated lower

If liquid or solids accumulate on the bottom of the pipe, the transducers have to be fixed

on the sides of the pipe (see Fig. 5.1).

Fig. 5.1: Positioning of the transducers on the pipe

5.2 Undisturbed Flow Profile

Many flow elements (elbows, slide valves, valves, control valves, pumps, reducers, dif-

fusers, etc.) distort the flow profile in their vicinity. The axisymmetrical flow profile needed

for correct measurement is no longer given. A careful selection of the measuring point

helps to reduce the impact of disturbance sources.

It is most important that the measuring point is chosen at a sufficient distance from any

disturbance sources. Only then it can be assumed that the flow profile in the pipe is fully

developed. However, measuring results can be obtained even if the recommended dis-

tance to disturbance sources can not be observed for practical reasons.

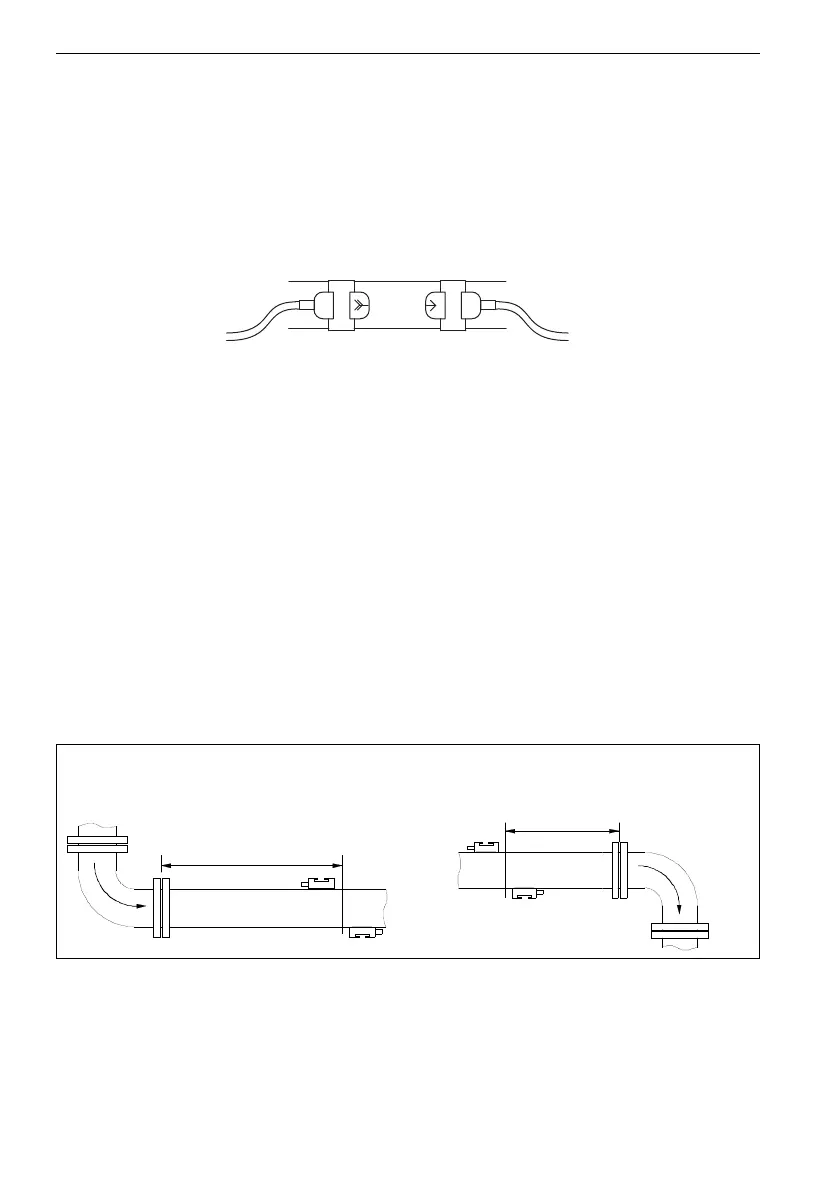

Recommended straight inlet and outlet pipe lengths are given for different types of flow

disturbance sources in the examples in Table 5.1.

Table 5.1: Recommended distance from disturbance sources

D = nominal pipe diameter at the measuring point, l = recommended distance

disturbance source: 90° elbow

supply: l 20D return: l 10 D

Loading...

Loading...