Establishing a

ground earth

connection

NOTE!

When establishing a ground earth connection, observe the following points:

▶

Use a separate return lead cable for each power source

▶

Keep the plus cable and return lead cable together as long and as close as

possible

▶

Physically separate the welding circuits of individual power sources

▶

Do not route several return lead cables in parallel;

if parallel routing cannot be avoided, keep a minimum distance of 30 cm

between the welding circuits

▶

Keep the return lead cable as short as possible, provide a large cable cross-

section

▶

Do not cross return lead cables

▶

Avoid ferromagnetic materials between the return lead cable and the inter-

connecting hosepack

▶

Do not wind up long return lead cables - coil effect!

Lay long return lead cables in loops

▶

Do not route return lead cables in iron pipes, metal cable conduits or on

steel rails, avoid cable ducts;

(routing of plus cables and return lead cables together in an iron pipe does

not cause any problems)

▶

If there are several return lead cables, separating the grounding points on

the component so that they are as far away from one another as possible is

recommended, as well as preventing crossed current paths from occurring

underneath the individual arcs.

▶

Use compensated interconnecting hosepacks (interconnecting hosepacks

with integrated return lead cable)

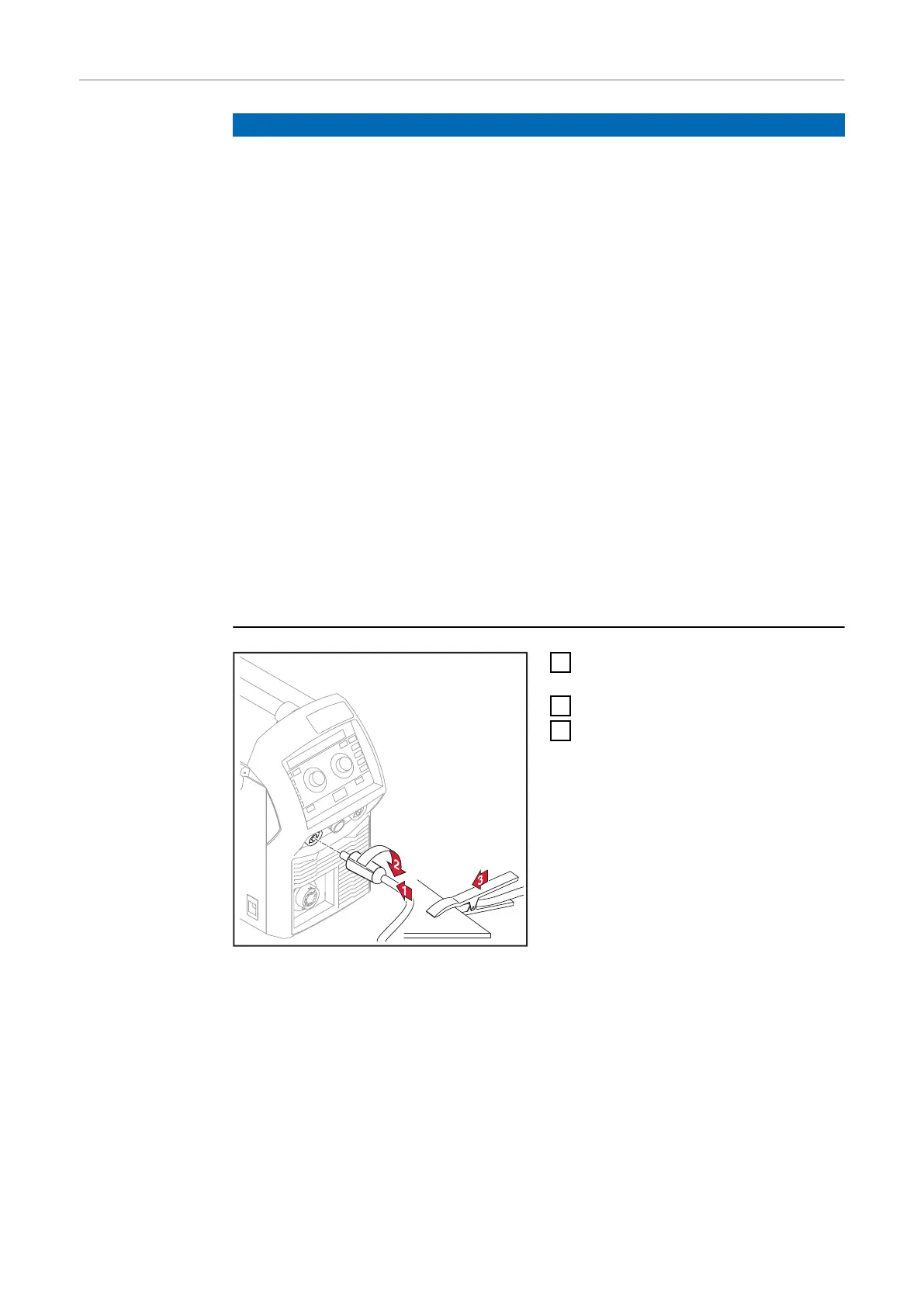

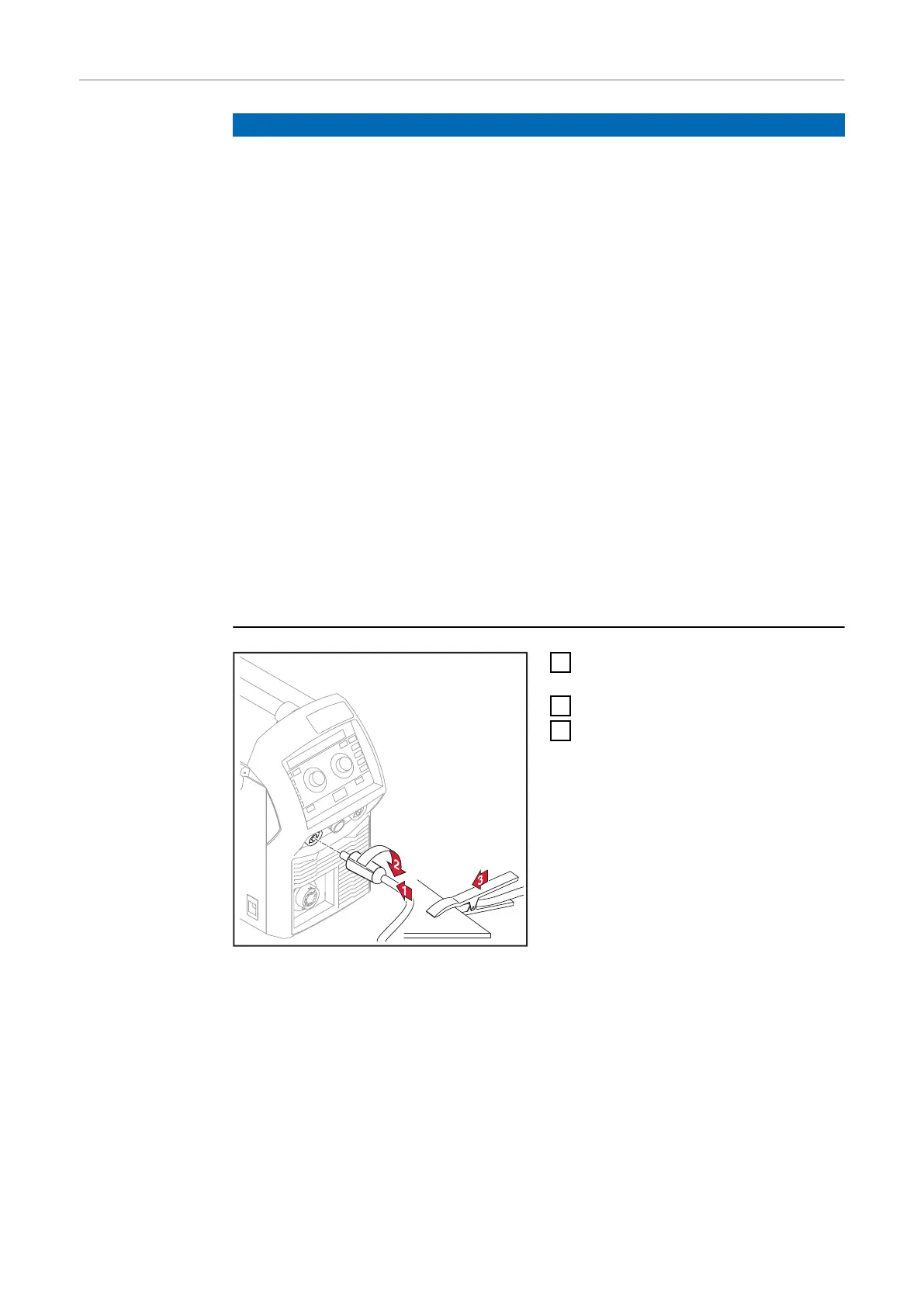

Connecting the return lead cable

1

Plug the return lead cable into the

(-) current socket

2

Lock the return lead cable in place

3

Use the other end of the return

lead cable to establish a connec-

tion to the workpiece

66

Loading...

Loading...