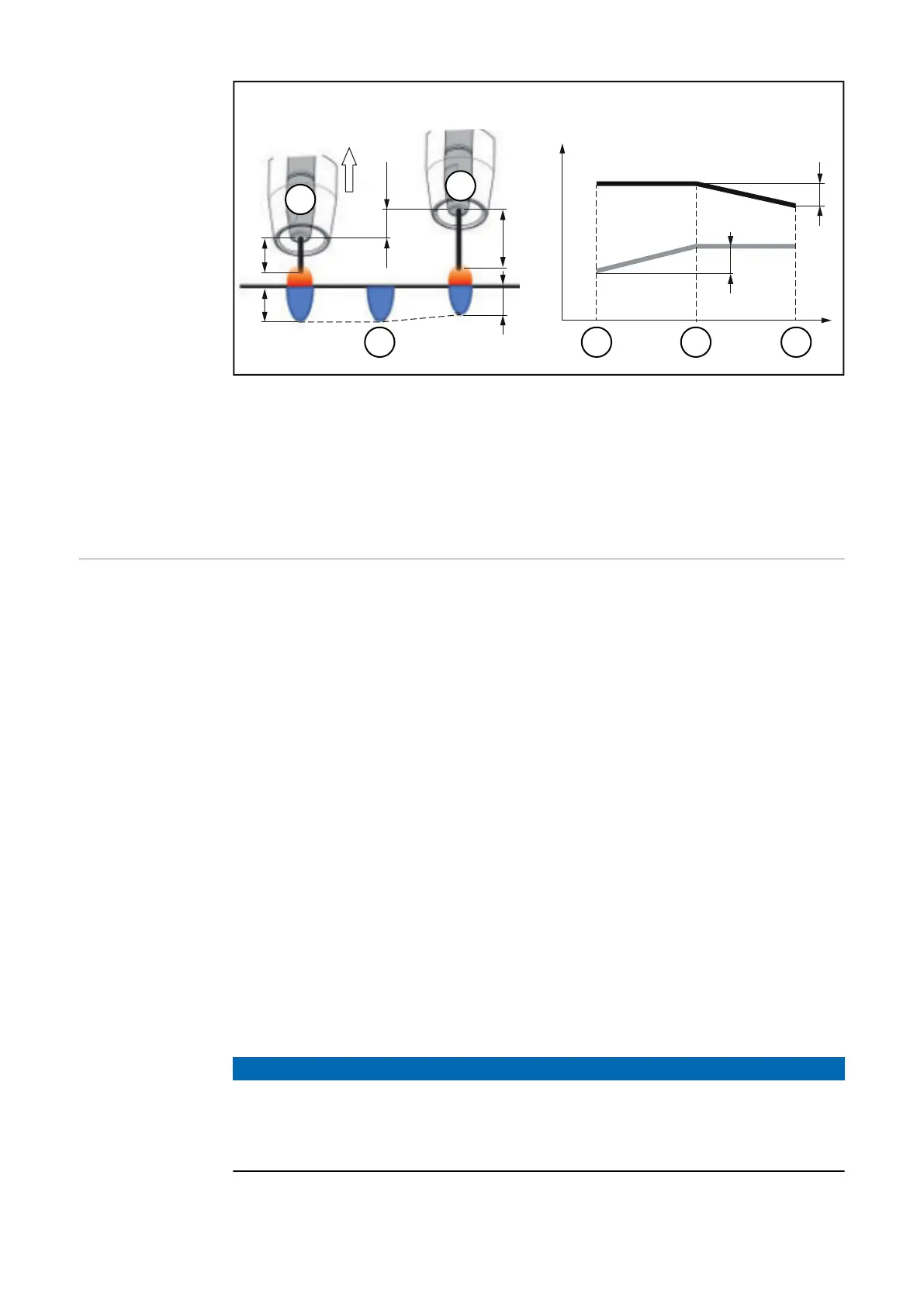

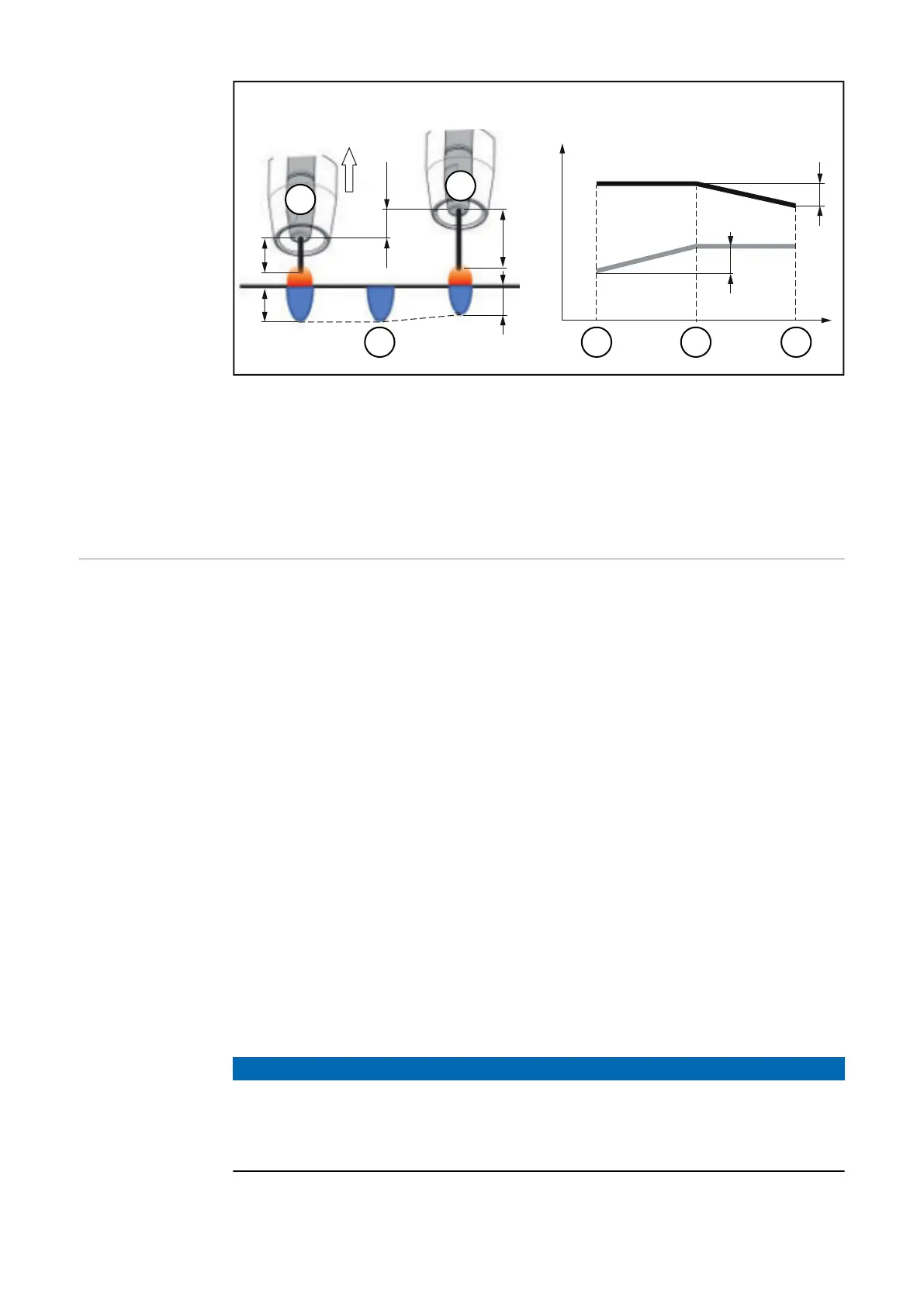

I [A]

v

D

[m/min]

1

3

1 2

3

h

s

1

s

3

x

1

x

3

t [s]

s

1

< s

3

x

1

> x

3

2

0,5 m/min

Penetration stabilizer = 0.5 m/min (activated)

To minimise the change in welding current if the stick out is changed (s

1

==> s

3

),

the wire speed is increased or reduced by 0.5 m/min.

In the example shown, the stabilising effect is obtained without a change in cur-

rent up to the set value of 0.5 m/min (Position 2).

I ... Welding current v

D

... Wire speed

Arc length sta-

bilizer

Arc length stabilizer

The arc length stabilizer forces short arcs, advantageous for welding, via a short

circuit current control and keeps them stable even with a variable stick out or ex-

ternal interference.

The arc length stabilizer welding parameter is only available if the WP PMC

(Welding Process Pulse Multi Control) option has been enabled on the power

source.

0.0 / auto / 0.1 - 5,0 (effect of stabilizer)

Factory setting: 0.0

0.0

The arc length stabilizer is deactivated.

auto

-

For inert gases (100% Ar, He, etc.) a value = 0 is stored.

-

For the remaining materials / gas combinations, a characteristic-dependent

value between 0.2 - 0.5 is stored.

-

From a wire speed of 16 m/min a value = 0 is deposited

0.1 - 5.0

The arc length stabilizer is activated.

The arc length is decreased until short circuits start to occur.

NOTE!

If the arc length stabilizer is activated, the normal arc length correction is only

effective at the start of welding.

▶

The arc length correction is then no longer displayed in the welding paramet-

ers.

112

Loading...

Loading...