58

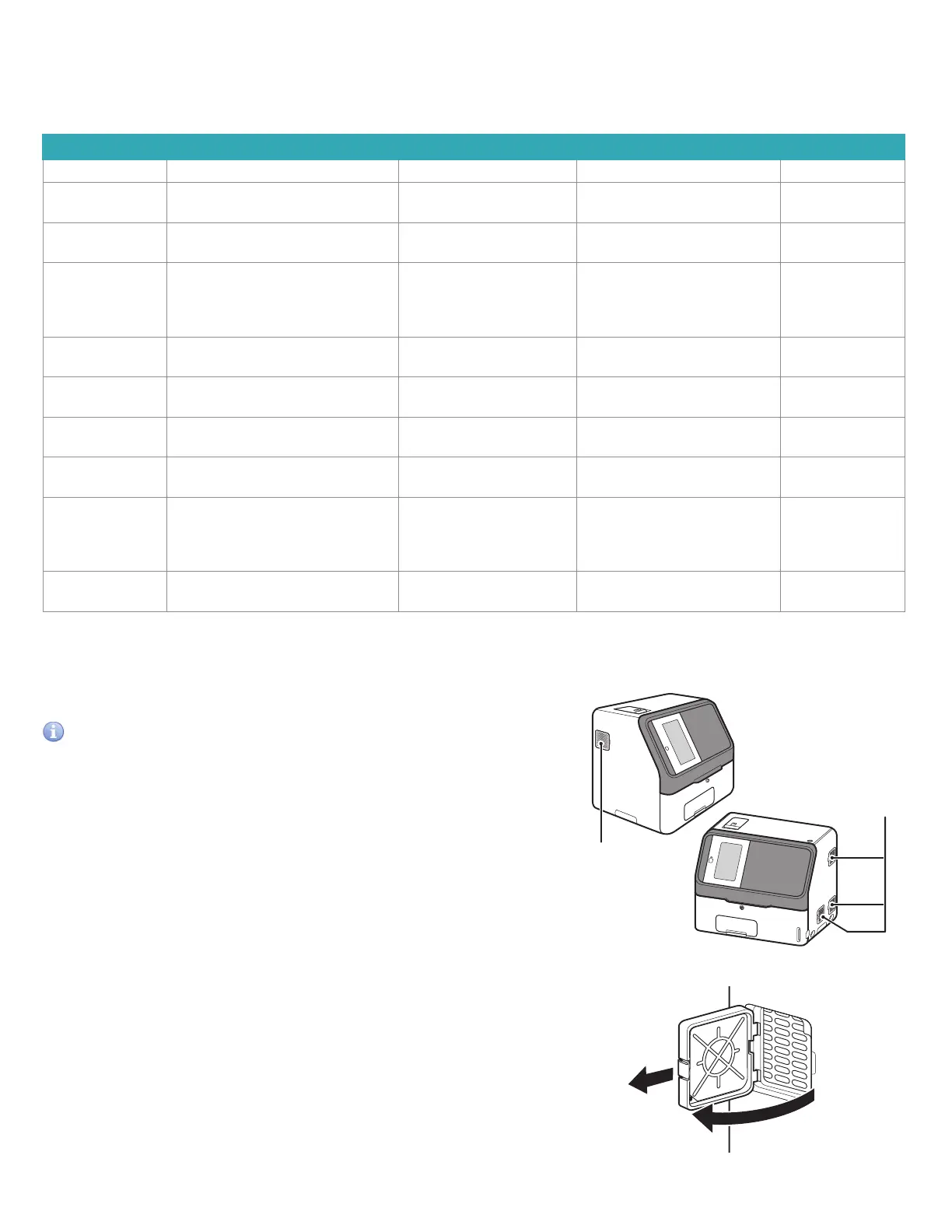

6.1 Periodic Maintenance Items

6.1.1 Items for daily and periodic inspection by the user

Users must perform the daily and periodic maintenance and replacement of parts in the following table.

Location Cleaning Interval Inspection Interval Replacement Interval Procedure

Air filter Once a month. - - Refer to Section 6.2

Transfer bar

Once every 3 months if inaccurate test

results occur, or if slide transfer error.

- - Refer to Section 6.3

Incubator

Once every 3 months or if inaccurate

test results occur.

- - Refer to Section 6.3

Spotting part

Once every 3 months along with

the incubator and ISE unit or if slide

transfer error or contamination with

sample occurs.

- - Refer to Section 6.3

ISE unit

Once every 3 months if inaccurate test

results occur.

- - Refer to Section 6.3

Slide reading

section

Once every 3 months or if frequent

reading errors occur.

- - Refer to Section 6.7

Sampler O-ring -

Perform leak check

procedure every 3 months.

- Refer to Section 6.6

Recording paper - -

Appearance of red lines on both

sides of paper.

Refer to Section 6.4

Light source lamp - -

When a photometer gain setting

error occurs or the lamp's

cumulative illumination time

exceeds 1,000 hours.

Refer to Section 6.5

Reference fluid cap

packing

When replacing reference fluid. - If it becomes cracked. Refer to Section 6.8

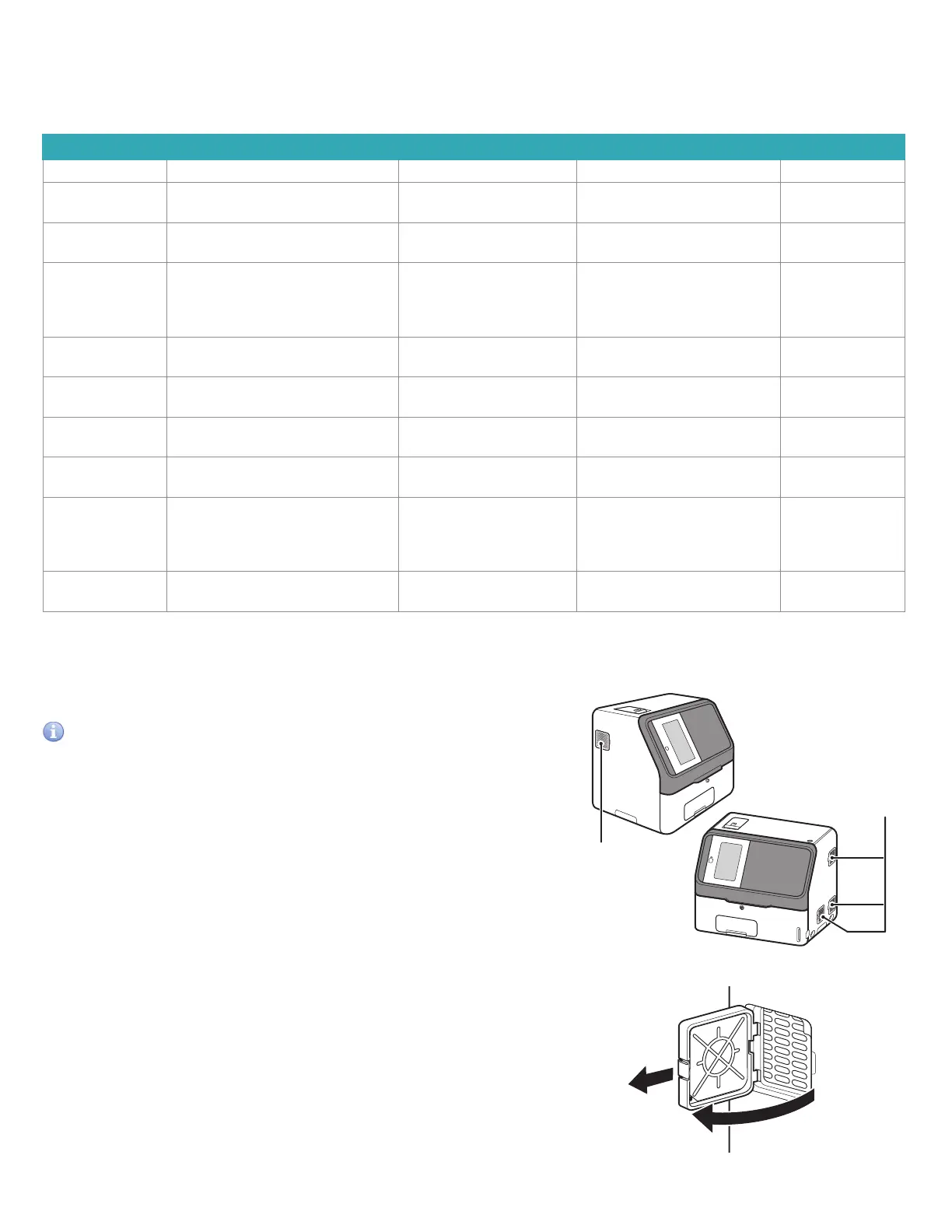

6.2 Cleaning the Air Filters

The air filters should be checked and cleaned once a month.

IMPORTANT

If the air filters are not cleaned, an increase in the temperature inside the

analyzer may negatively affect the measurement values.

NOTE: Clean all 4 filters.

1. Switch off the analyzer power.

Louver

Louver

1

2

2. Remove the four louvers and pull out the air filters located inside

of the louvers. Lift the louver upward #1, then pull forward #2 to

remove.

Loading...

Loading...