Components and Architecture - I/O Network

28 HC900 Process Controller Installation and User Guide Revision 19

06/14

I/O Network

I/O Expansion Network (C50 and C50S/C70 and C70S CPU only)

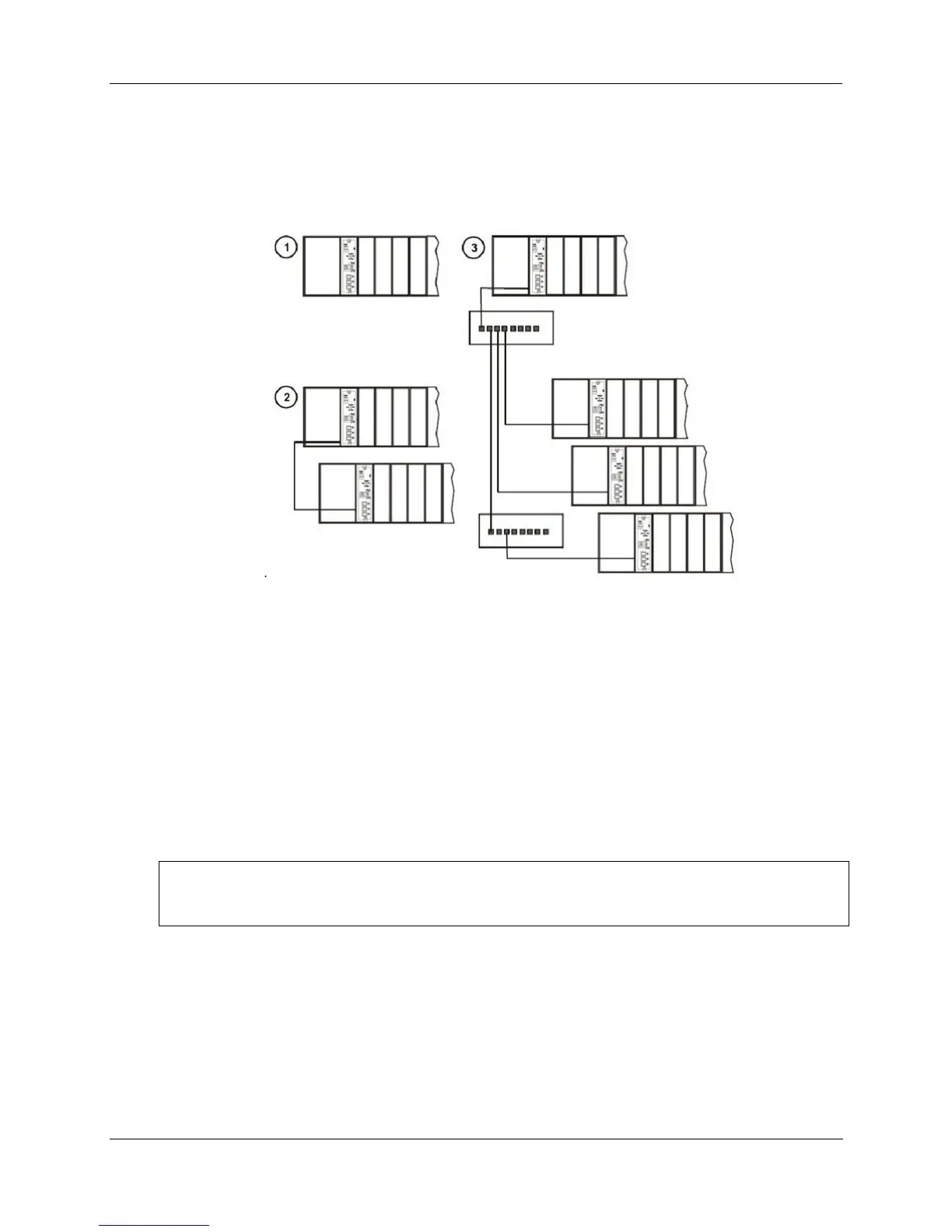

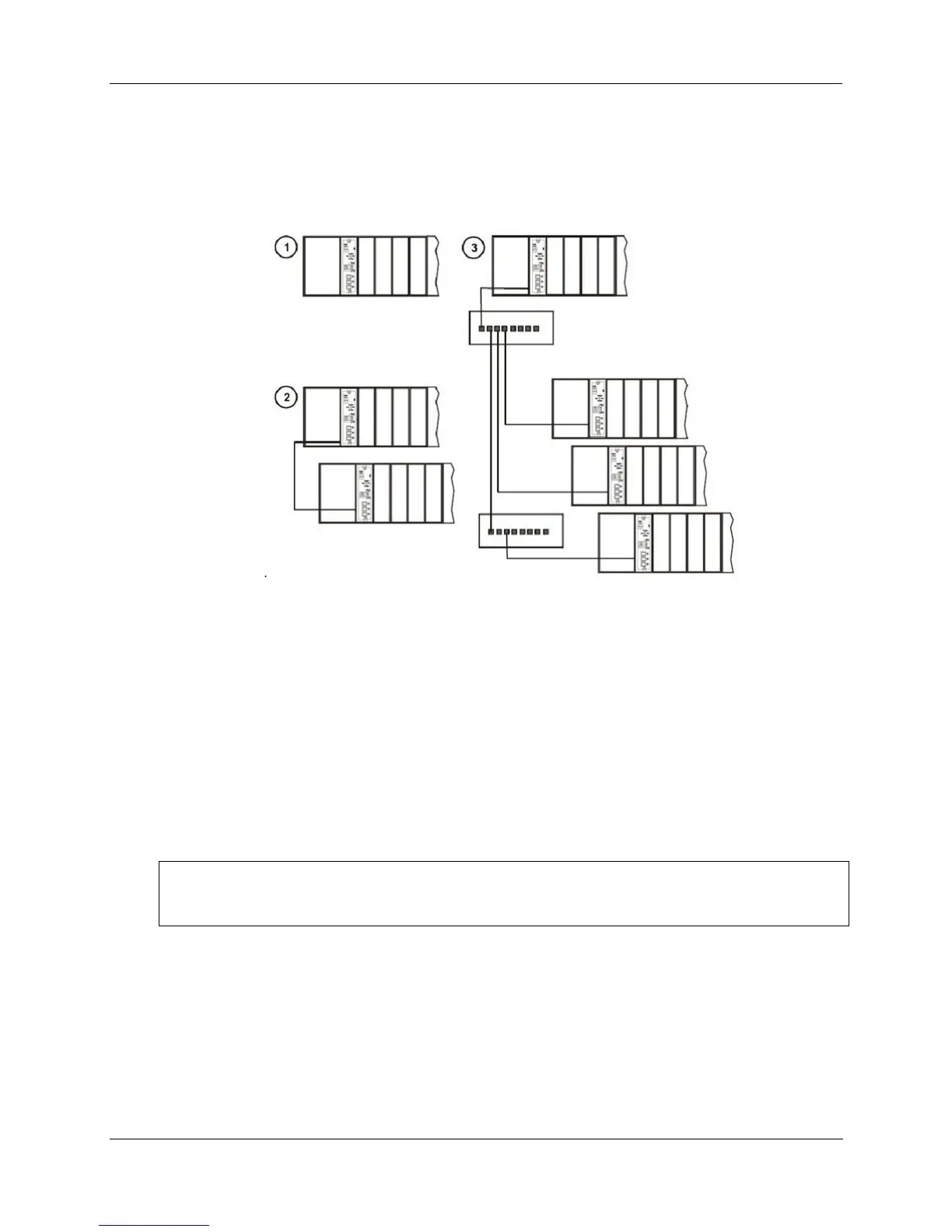

Examples of HC900 Controller I/O expansion configurations are shown in Figure 18.

.

Figure 18 – HC900 Controller Configurations

In any of the racks shown in each controller configuration can be 4-, 8-, or 12-slot versions.

The Ethernet cables for the I/O expansion links are standard shielded Cat 5 IO cables, with standard RJ45

connectors. Each cable segment can be up to 100 meters (328 feet) long.

You can also use fiber optic cable for connections between the controller and a remote rack. Distances up

to 750m (2460 ft.) are possible with one fiber cable. Distances up to 1500m (4920 ft.) are possible with a

fiber switch used as a repeater at the midpoint. (See page 204)

Configuration 1 is the C50/C70 CPU with I/O but no I/O expansion racks.

Configuration 2 shows the C50/C70 CPU with 1 I/O expansion rack. The Ethernet cable connects directly

between the 10Base-T connectors on the C50 CPU Controller Module and the Scanner Module.

ATTENTION:

For 2 or more I/O expansion racks a switch is required. Use only Honeywell recommended switches (part

no. 50008930-001). The total number of switches is limited to 2 in series between a CPU and its scanners.

Configuration 3 shows the C50/C70 CPU with 3 I/O expansion racks. Since there are at least 2 I/O

expansion racks a switch is required. When an Ethernet switch is used to connect to expansion I/O, a cable

goes between the I/O port on the controller to the switch. Two cables go from the switch to 2 scanners. A

third cable goes from the switch to a second switch, which connects to a third remote scanner.

I/O implementation requirements include:

Constructing a configuration file, and loading it into the Controller Module. This file includes I/O

numbering assignments for each I/O Function Block regarding Rack Number, Module Number ("slot"

number, or position in the rack, starting from the left), and Channel Number.

Loading...

Loading...