Revision 19 HC900 Process Controller Installation and User Guide 1

06/14

Introduction

Purpose

This publication describes the installation, operation, and maintenance of the Honeywell HC900 Process

Controller. This publication includes the following sections.

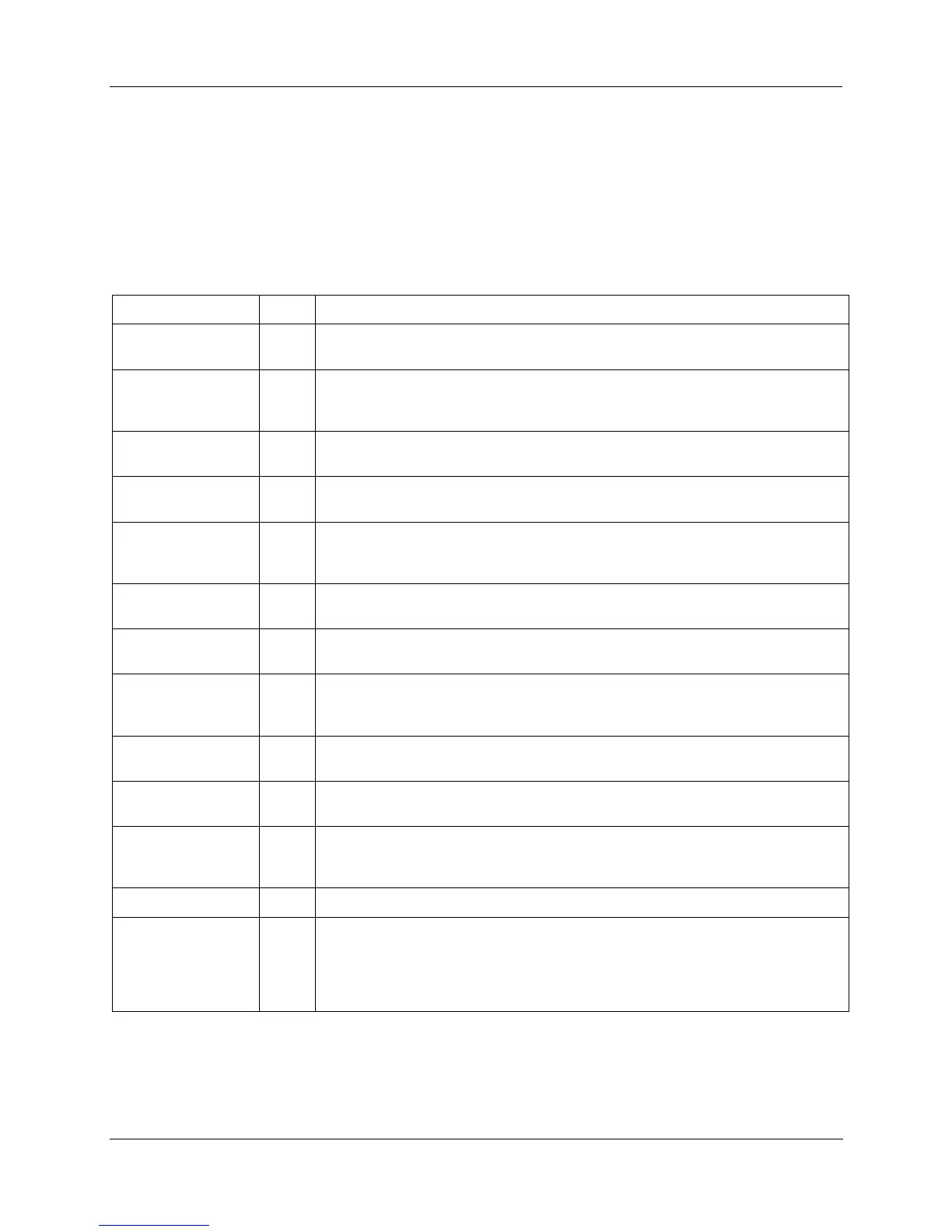

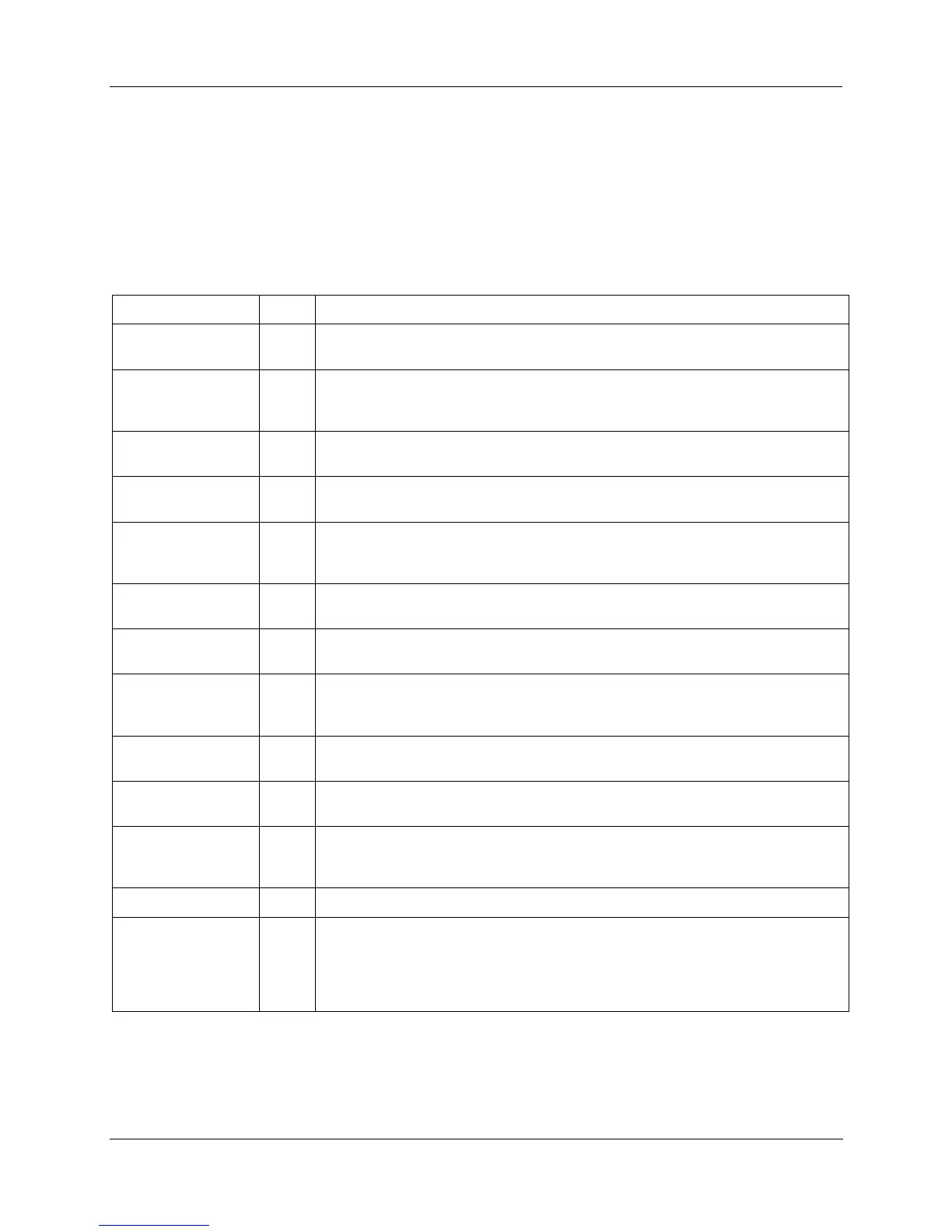

Chapter Title Page Content

Introduction 1 Model numbers, how to verify component compatibility, function description of

components, feature summary.

Components and

Architecture

13 Functional features and physical characteristics of the system and of each major

component of the HC900 Process Controller. Networking components and

methods of interconnection.

Pre-Installation

Planning

37 Pre-planning considerations and procedural guidelines for planning an installation.

Rack Installation 55 Procedures for installing the major components of the system: controller rack, I/O

expansion racks, and communication interconnections.

I/O Module

Installation and

Wiring

66 Procedures for installing I/O modules in the controller rack and I/O expansion

racks, and for wiring field devices to the terminal block associated with each

I/O module.

Communications

Installation

117 Guidelines for installing RS-232, RS-485 TO USB CABLE, RS-485,and Ethernet

cabling and associated components.

Operating

Characteristics

145 Characteristics of the HC900 Process Controller as they relate to configuration of

a control strategy, and to operation of an installed and running system.

Redundant

Operating

Characteristics

155 Characteristics of redundant operation.

Diagnostics and

Troubleshooting

161 Mechanisms that detect and react to faults in the operation of HC900 Process

Controller hardware and/or software components.

Analog Calibration 180 Hardware configuration required for calibrating AI and AO modules from the

configuration software.

Removal and

Replacement

Procedures

184 Guidelines for replacing system components; includes Cautions and Warnings as

applicable.

Specifications 194 Details of HC900 Process Controller design and functioning.

Appendix -

Installation of

Remote

Termination Panels

(RTPs)

207 The Remote Termination Panel (RTP) provides an easy way to connect the

HC900 controller to the field wiring. The RTP integrates some of the typical

externally connected components, reducing wiring and setup time. It also

minimizes the need for multiple wires under a single screw connection by

expanding the connectivity of the shared terminals of the I/O modules.

Loading...

Loading...