Rack Installation - Overview

56 HC900 Process Controller Installation and User Guide Revision 19

06/14

Equipment Preparation

A checklist for site preparation is given in Table 7.

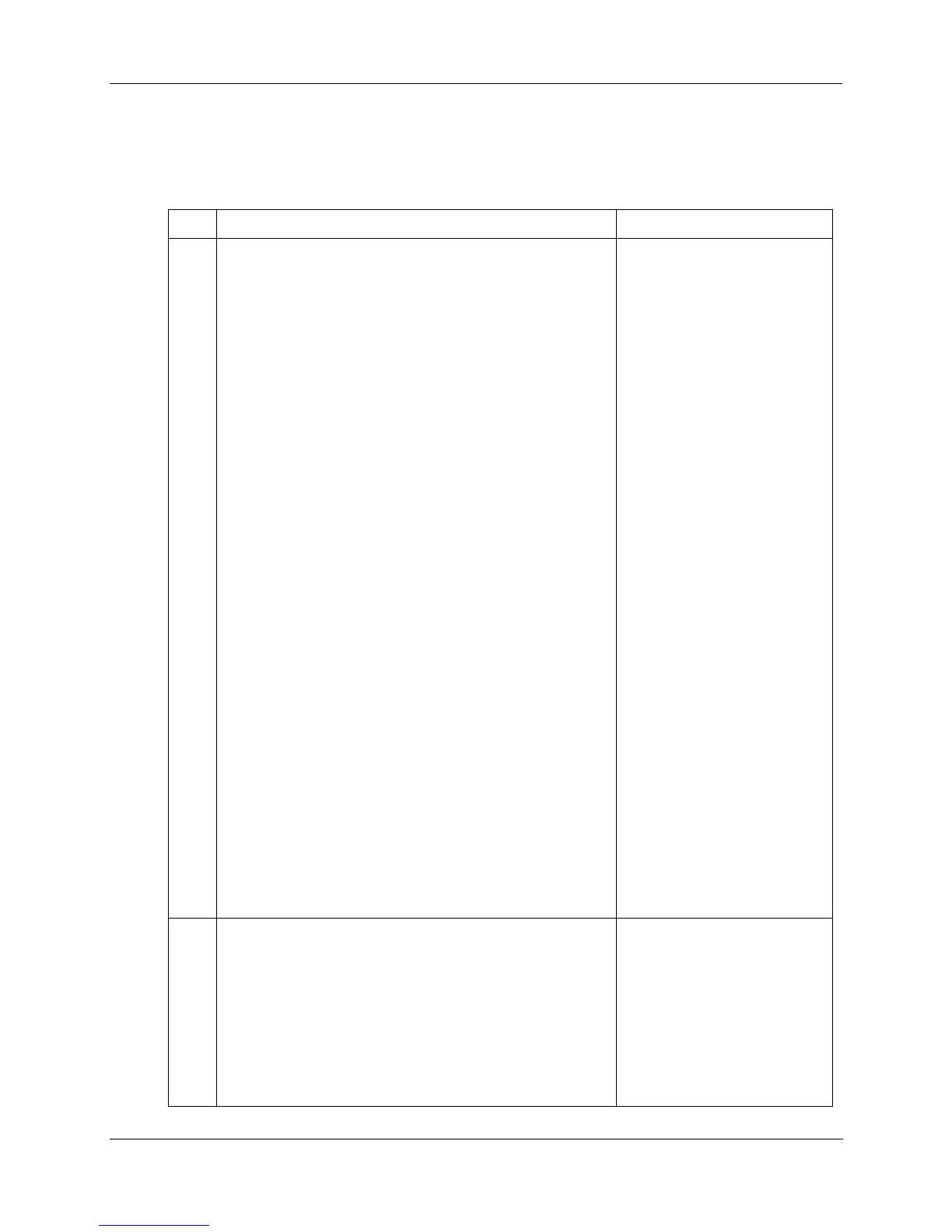

Table 7 – Site and Equipment Preparation

Step Procedure Reference

1 Verify that sufficient numbers of the following items are on

hand:

• Racks (4-, 8- and 12-slot)

• Power Supplies: 1 per rack

• C30/C50/C70 Controller Module or Scanner 1 port (1 per

rack)

• Redundancy:

− Each Controller Rack: 2 Power Supplies, 2 C75 CPUs,

1 Redundancy Switch Module.

− Each I/O Rack: 1 Scanner dual-port module, 1 Power

Supply, 1 reserve Power Supply (optional), 1 Power

Status Module (optional)

• I/O Modules (correct type for each configured slot)

• Terminal Blocks, Barrier or Euro style, (1 for each I/O

Module)

• Jumpers 2-position or 10-position, (for designated

Terminal Blocks)

• Tie Wraps (1 or 2 for each Terminal Block)

• I/O Label (one per terminal block, by module type)

• Filler Block Cover (1 for each slot not occupied by an

I/O Module)

• Blank label (1 for each Filler Block Cover)

• Grounding Bars for I/O wiring shields (1 or 2 for each 4-

slots in each rack)

• Wiring terminal lugs (for connecting I/O shields to

grounding bars)

• Sheet metal screws, steel #10 or M4, for mounting racks

in enclosures (4 screws for 4-slot racks, 8 screws for 8- or

12-slot racks)

• Section on Pre-Installation

Planning.

• Sections on installation

2 Install (or verify correct installation of) enclosures for HC900

Controllers and ancillary equipment:

• Mounting rails or flat-panels

• (for cabinet with multiple HC900 Chassis):

− grounding bus

− barrier strip for AC power

• Master control Relay

Mount Racks

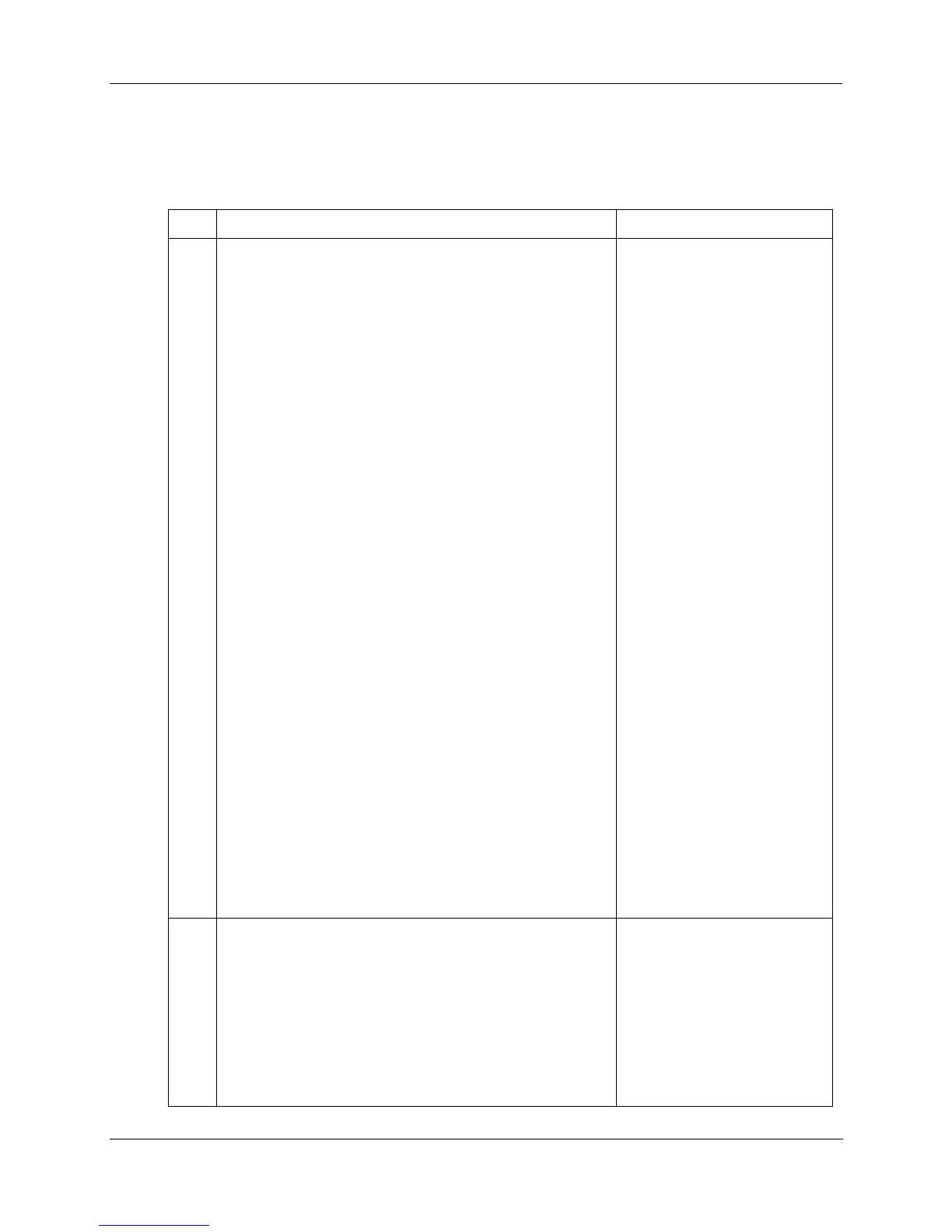

Table 8 – Mount Rack

Loading...

Loading...